Static countermeasure parts

A countermeasure and component technology, applied in the field of electrostatic countermeasure components, can solve problems such as the inability to use high-speed transmission circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

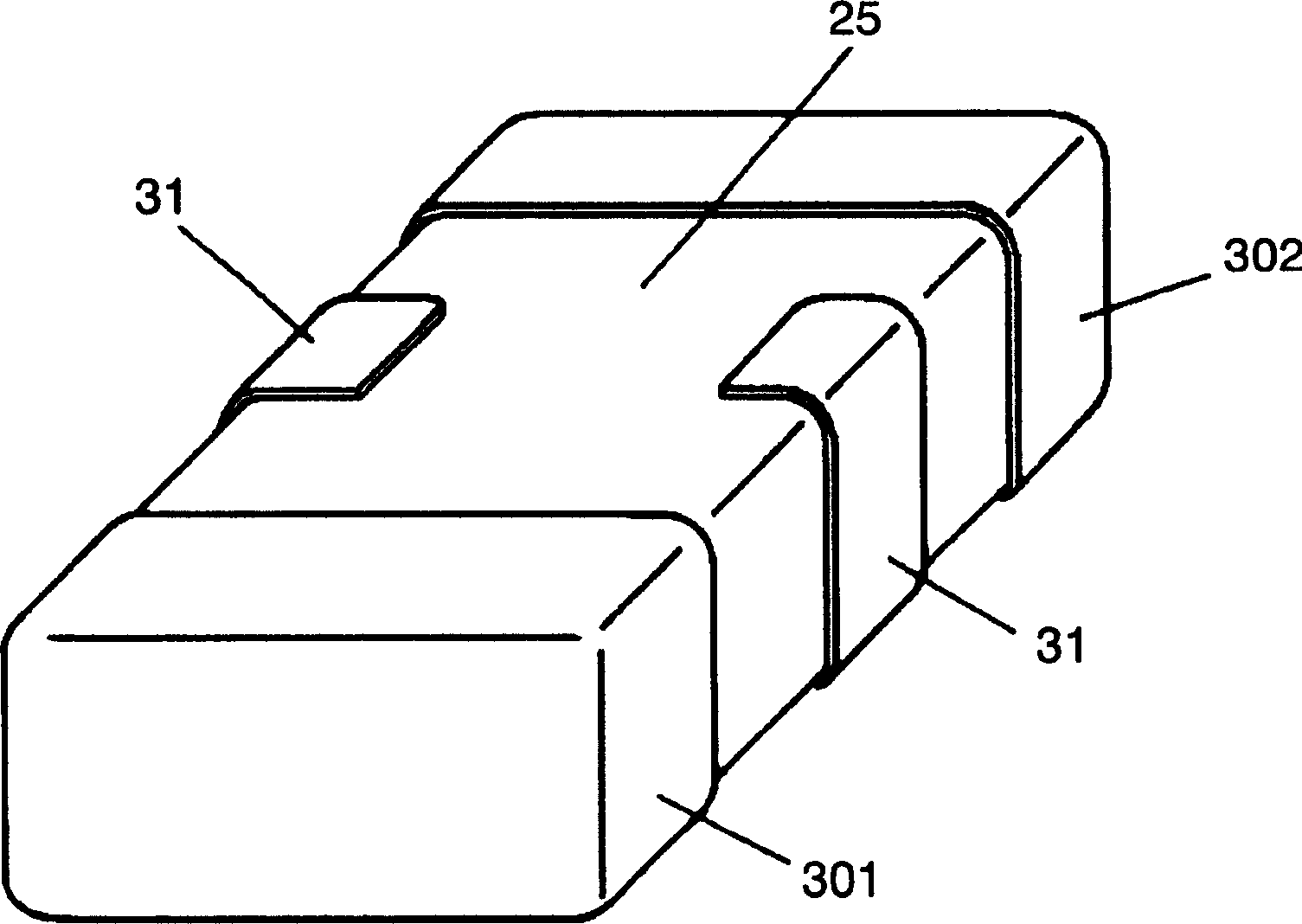

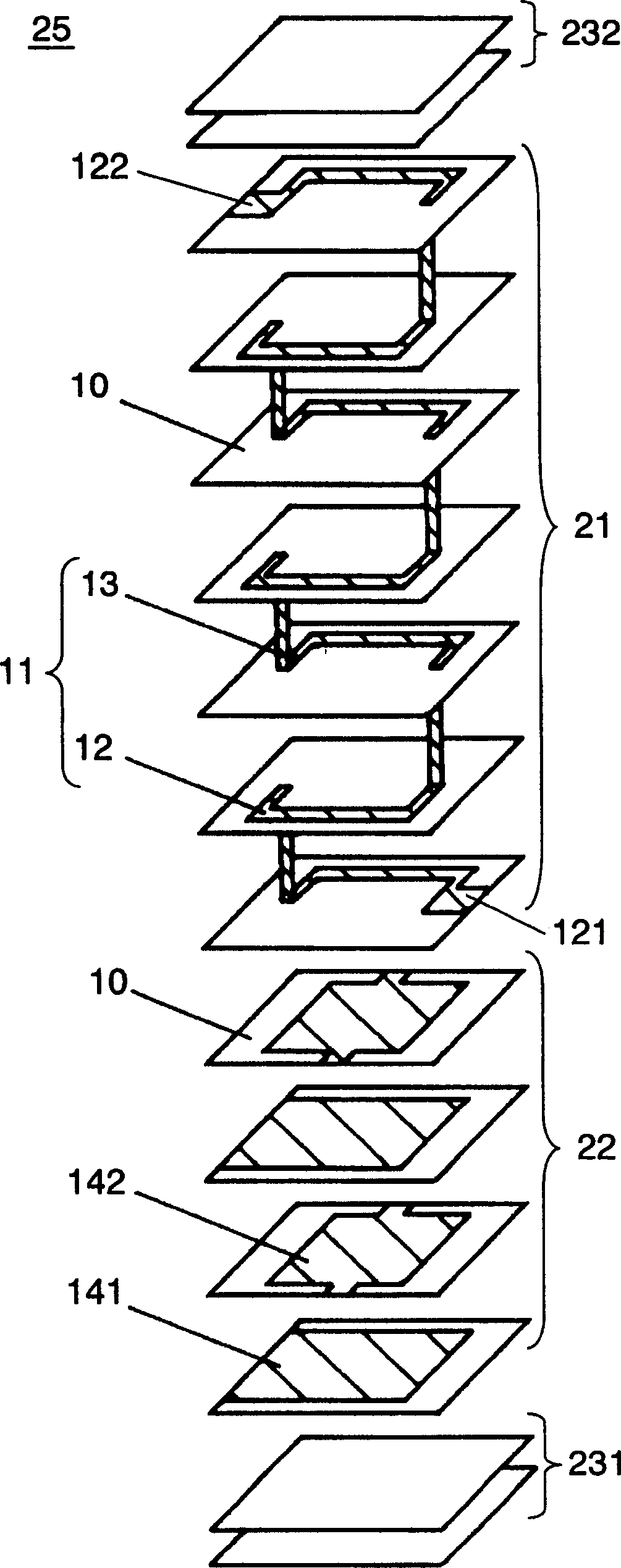

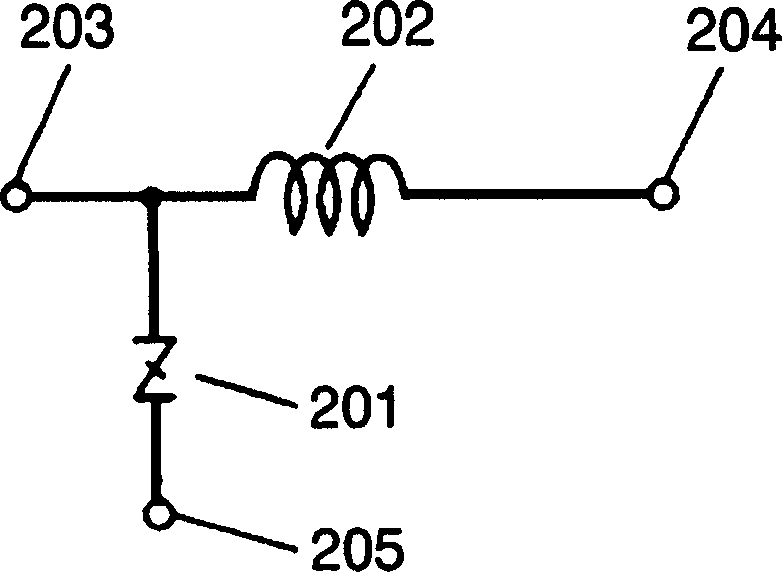

[0037] figure 1 It is a perspective view of the appearance of the static electricity countermeasure component according to Embodiment 1 of the present invention, figure 2 It is a schematic exploded perspective view showing disassembled ceramic sintered compacts constituting the static electricity countermeasure component. image 3 It is an equivalent circuit diagram of this static electricity countermeasure component.

[0038] The static electricity countermeasure component of the present invention is configured by providing input external electrodes 301 and output external electrodes 302 on both short sides of ceramic sintered body 25 and providing grounding external electrodes 31 on both long sides. figure 2 The inner structure of the ceramic sintered body 25 is shown in . The ceramic sintered body 25 is integrally formed by stacking a varistor part 22 , an inductor part 21 , and inactive layers 231 and 232 as surface protection layers.

[0039] The shape of the inducto...

Embodiment 2

[0062] Figure 10 It is a schematic exploded perspective view of the ceramic sintered body 40 constituting the static electricity countermeasure component in Example 2 of the present invention. Figure 11 This is an equivalent circuit diagram of the static electricity countermeasure component. The static electricity countermeasure component of this example differs from the static electricity countermeasure component of Example 1 in the structure of the ceramic sintered body. That is, the present embodiment is characterized in that one inductor portion and two varistor portions are formed in a ceramic sintered body. The appearance and shape of the electrostatic countermeasure parts of this embodiment are the same as those of Embodiment 1, so use figure 1 Be explained. Also, the same symbols are assigned to the same components.

[0063] The ceramic sintered body 40 constituting the electrostatic countermeasure component of this embodiment is integrally formed by stacking the...

Embodiment 3

[0082] Hereinafter, a static electricity countermeasure component according to Embodiment 3 of the present invention will be described in detail with reference to the drawings. Figure 14 It is a schematic exploded perspective view of the ceramic sintered body 50 constituting the static electricity countermeasure component of this embodiment. Figure 15 This is an equivalent circuit diagram of the static electricity countermeasure component.

[0083] The static electricity countermeasure component of this example differs from the static electricity countermeasure components of Example 1 and Example 2 in the structure of the ceramic sintered body. The present embodiment is characterized in that two inductor parts and three varistor parts are formed in a ceramic sintered body. However, the appearance of the static electricity countermeasure components of this embodiment is the same as that of the static electricity countermeasure components of Embodiment 1 and Embodiment 2, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com