Process for producing transfer printing films having a dull surface and a bright surface, and product made thereby

A production method and technology of transfer film, applied in transfer printing, rotary printing machine, copy/marking method, etc., can solve the problems of slightly matte surface and inapplicability of the product, so as to increase the decoration and the hand feeling. , the effect of reducing trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

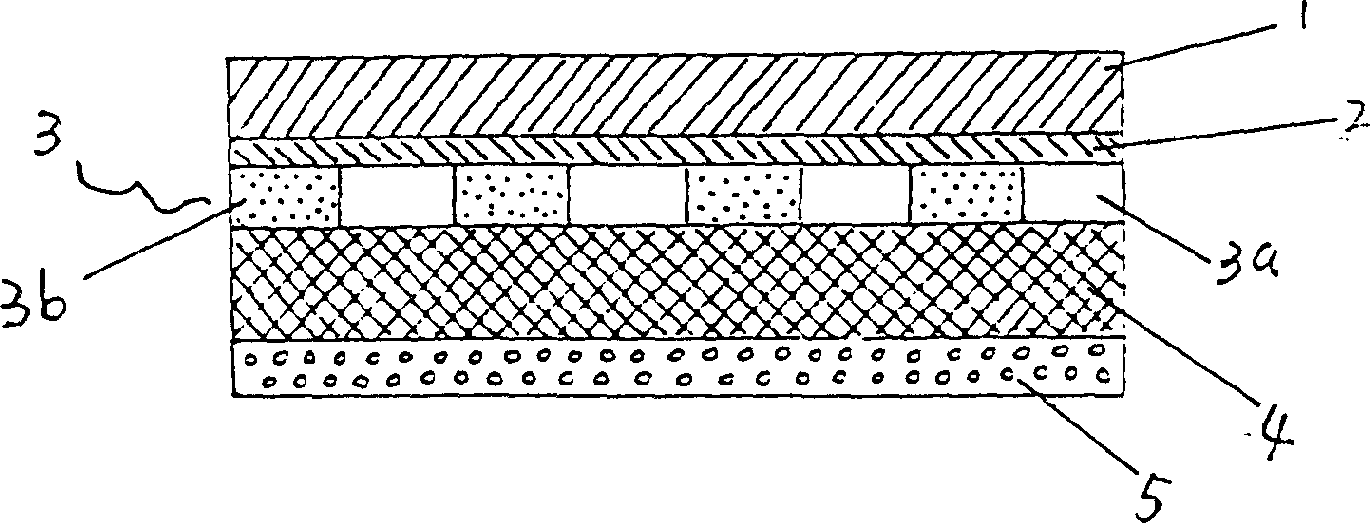

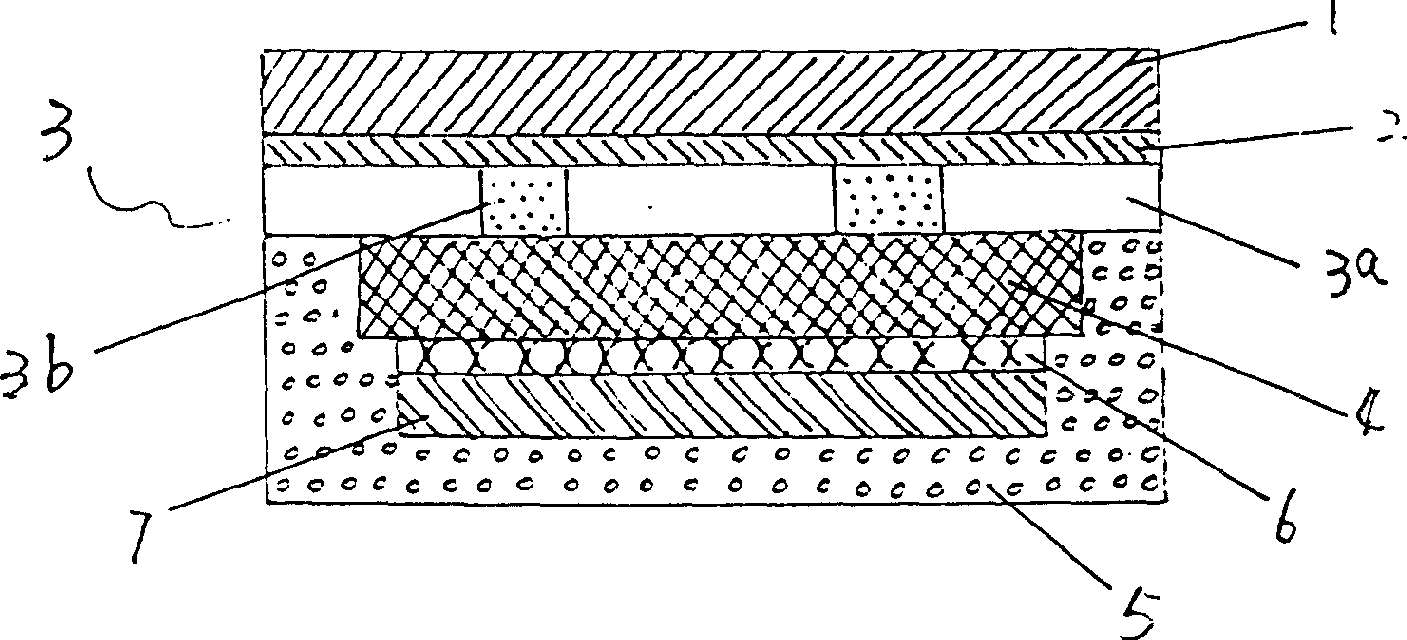

[0040] Such as figure 1 , 2 As shown, the top layer of the transfer film is a transparent PET film 1, the second layer is a wax layer 2, and the third layer is a protective layer 3. This layer is divided into two regions 3a and 3b, and they are arranged alternately. The surface of 3a is smooth. It has a high reflectivity to light and presents a bright surface. The surface of 3b is relatively rough, which produces diffuse reflection to light and presents a matte surface; the fourth layer is the ink graphic layer 4; the fifth layer is the glue layer 5. The production method is: (1) first coat a continuous wax layer on the PET film, that is, step A, (2) on the wax layer, use a printing machine to print a wax layer added with carbonic acid at a certain distance. Salt acrylic resin layer (the amount of carbonate depends on the roughness of the matte layer, its content in the resin layer can be 1%-60%, the same below), and then print an acrylic layer on the remaining area Resin la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com