Method for making metal die part for plate-processing machine tool

A technology for metal mold and sheet metal processing, which is applied in the field of metal mold parts for manufacturing machine tools for sheet metal processing, and can solve the problems of long time, time-consuming, and inability to fully and effectively exert the production potential of the manufacturing plant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

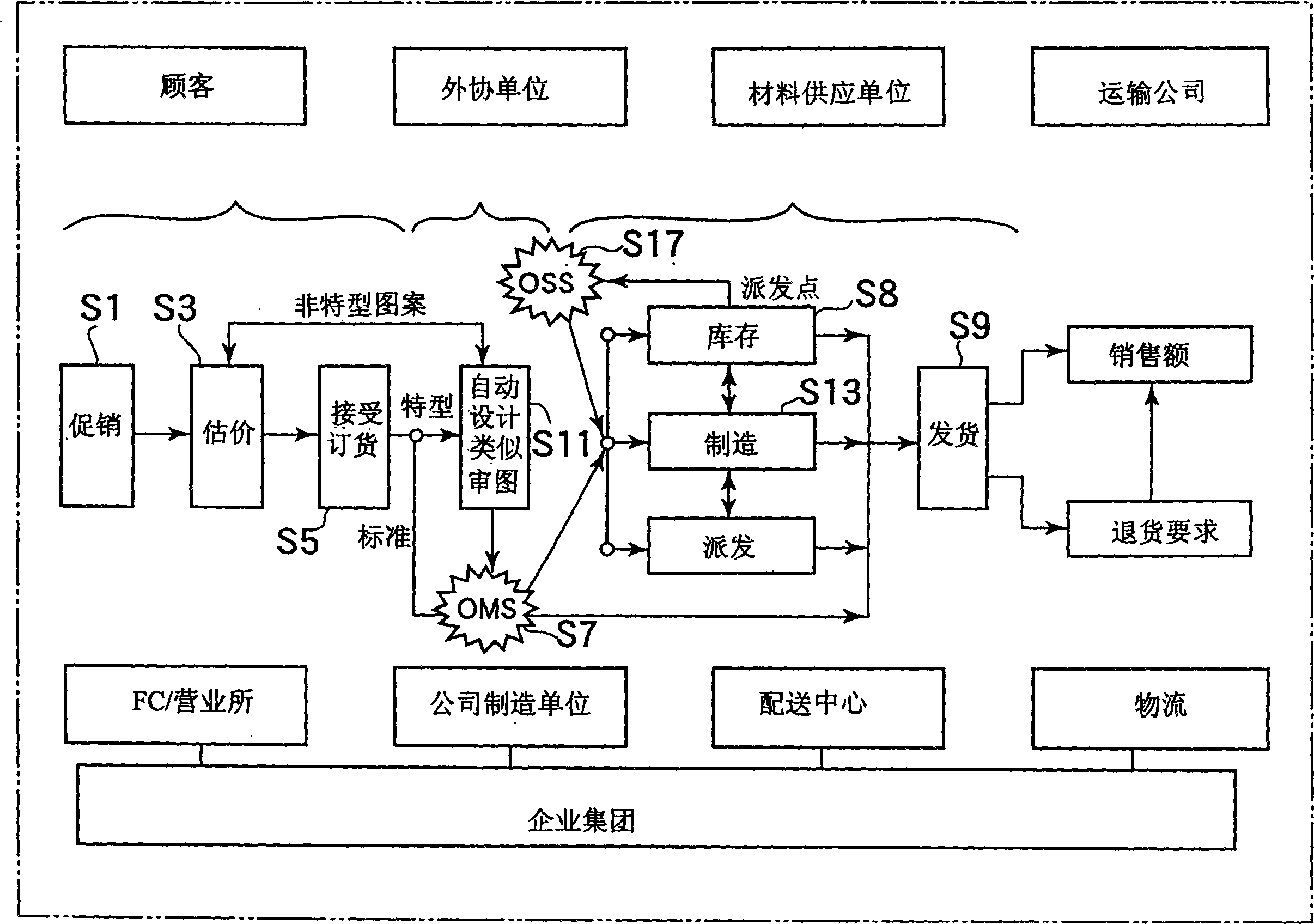

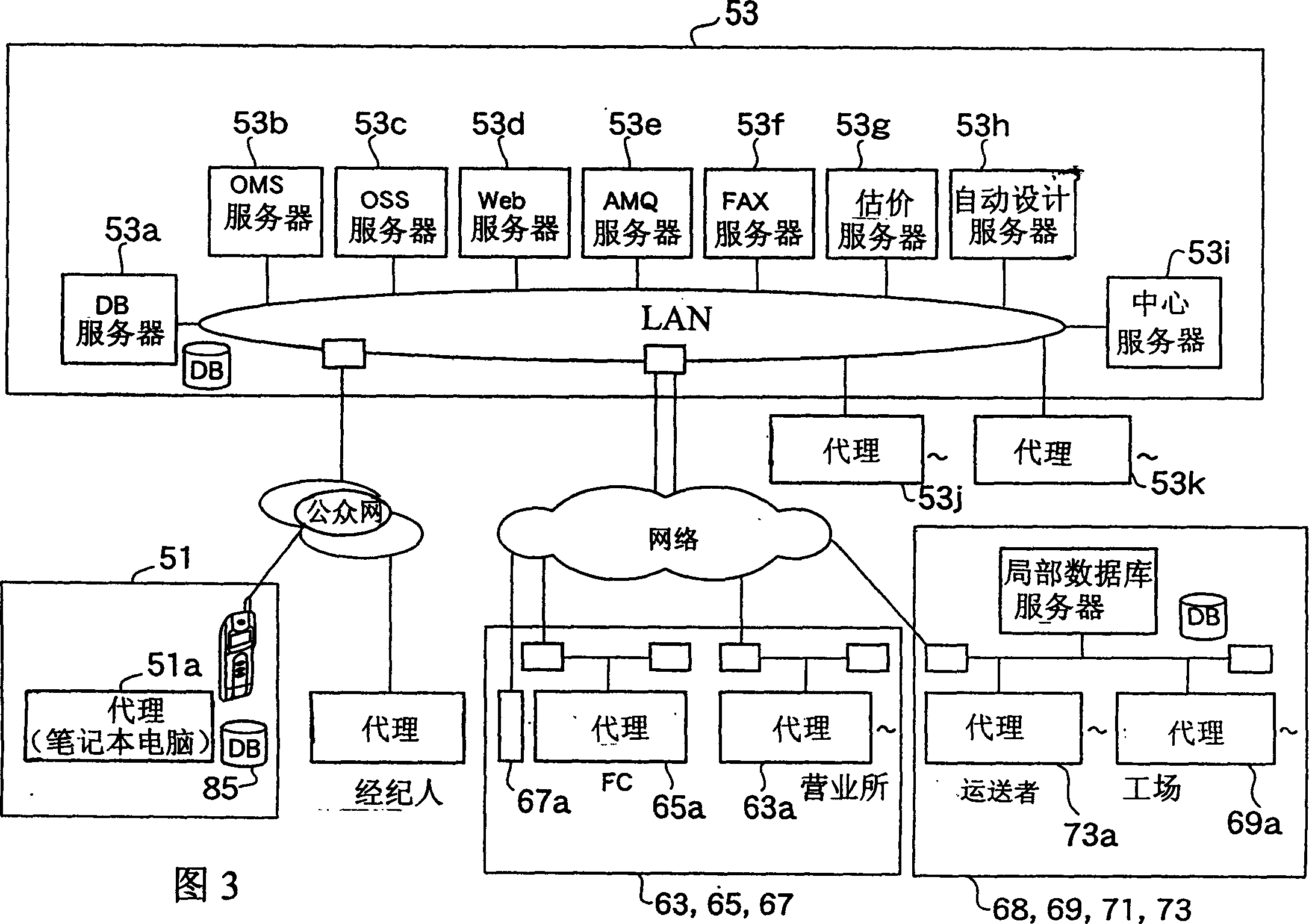

[0088] Embodiments of the sales support system and the method of manufacturing metal mold parts of a machine tool for sheet metal processing according to the present invention will be described below with reference to the drawings.

[0089] The sales support system of this embodiment is a sales support system for selling tools as commodities or products. (These tools are especially punches and dies of turret punch presses or punches and dies of plate bending machines, etc.).

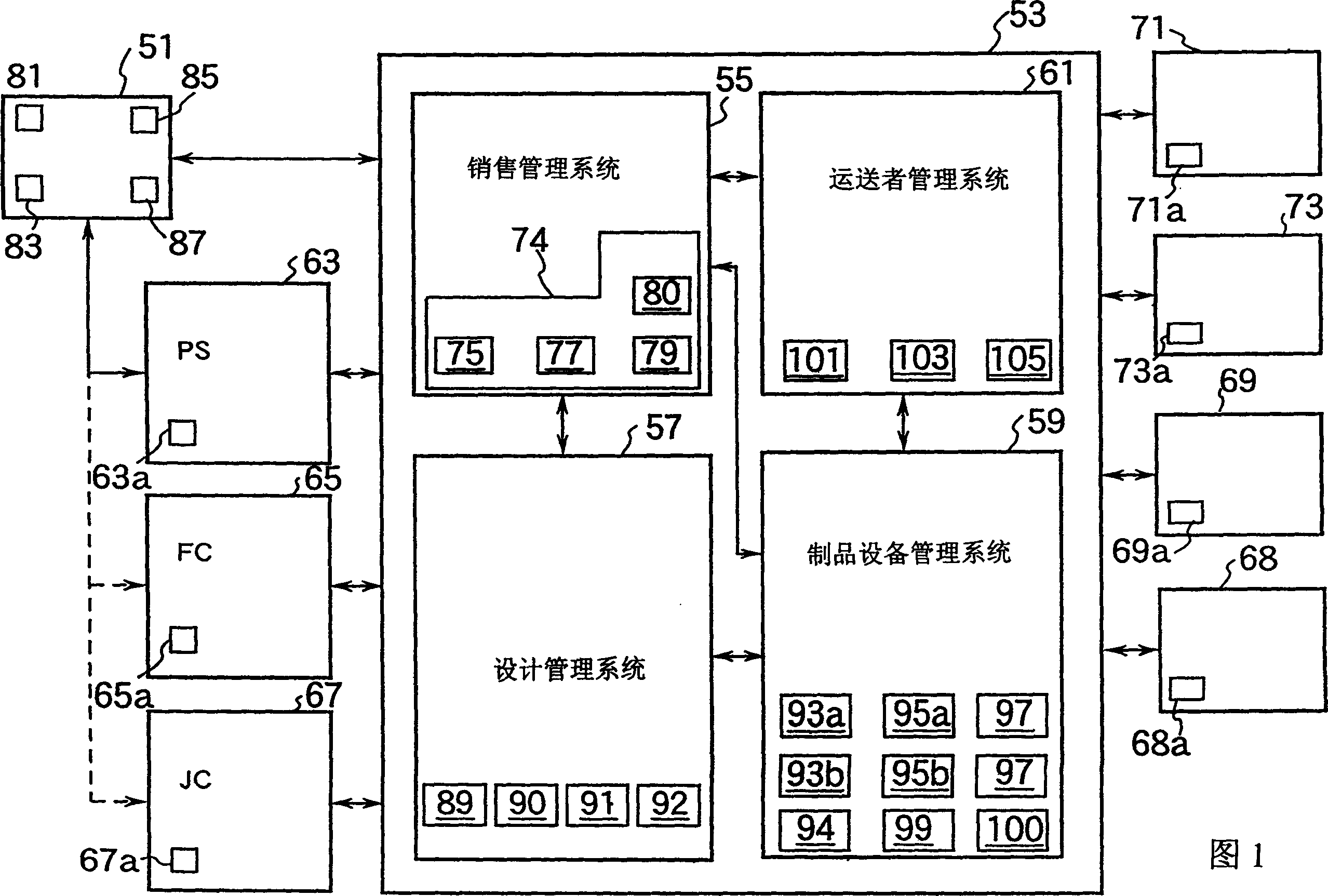

[0090] Fig. 1 is a block diagram showing the outline of this embodiment.

[0091] As shown in FIG. 1, this sales support system has a terminal system 51 equipped with an input device 81 for inputting product-related information desired by customers and a display device 83 for displaying product-related information to customers. Here, the product information required by the customer includes a purchase order for the product.

[0092] In addition, the sales system includes an information management syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com