Field maintenance tool with improved device description communication and storage

A technology for equipment description and maintenance tools, which is applied in the direction of comprehensive factory control, comprehensive factory control, signal transmission system, etc., and can solve problems such as defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An improved field maintenance tool is used to maintain two-wire and four-wire (ie, external power) field devices using one or more process measurement and control protocols. Configuration and calibration are preferably supported by DDL techniques. DDL technology is well known and additional reading on Device Description Language can be found in US Patent 5,960,214 to Sharp Jr. et al.

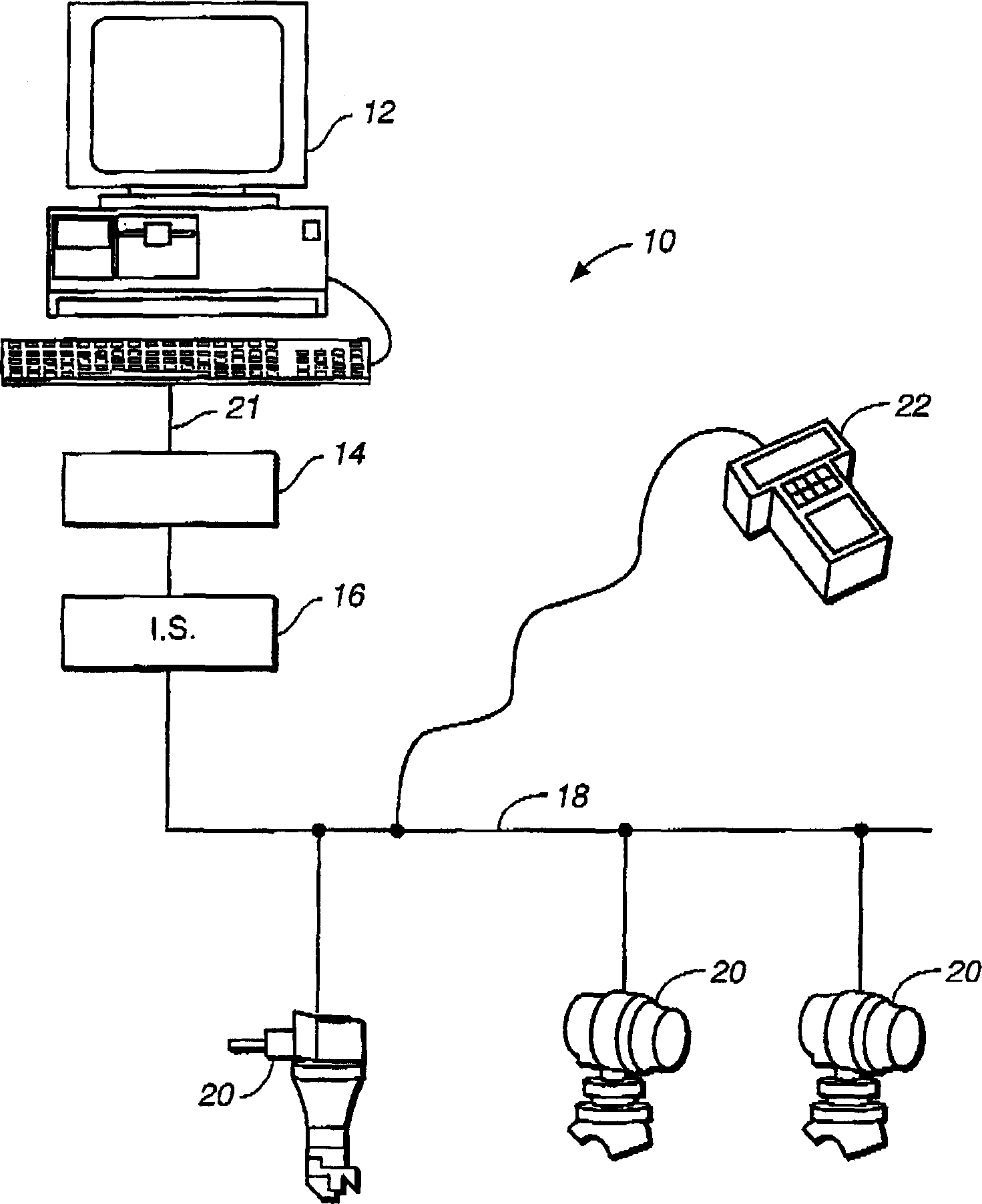

[0016] figure 1 A typical system in which embodiments of the invention are useful is shown. System 10 includes controller 12 , I / O and control subsystem 14 , intrinsically safe (IS) barrier 16 , process communication loop 18 , and field devices 20 . Controller 12 is connected to I / O and control subsystem 14 by link 21, which may be any suitable link such as a local area network (LAN) operating according to an Ethernet signal control protocol or any other suitable protocol. I / O and control subsystem 14 is connected to intrinsically safe barrier 16, which in turn is connected to process ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap