Safe pipeline digging system and its digging method

A safety and pipeline technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve problems such as not yet practical, difficult to apply optical cable, etc., to improve safety and efficiency, The effect of high efficiency and safety, safe excavation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

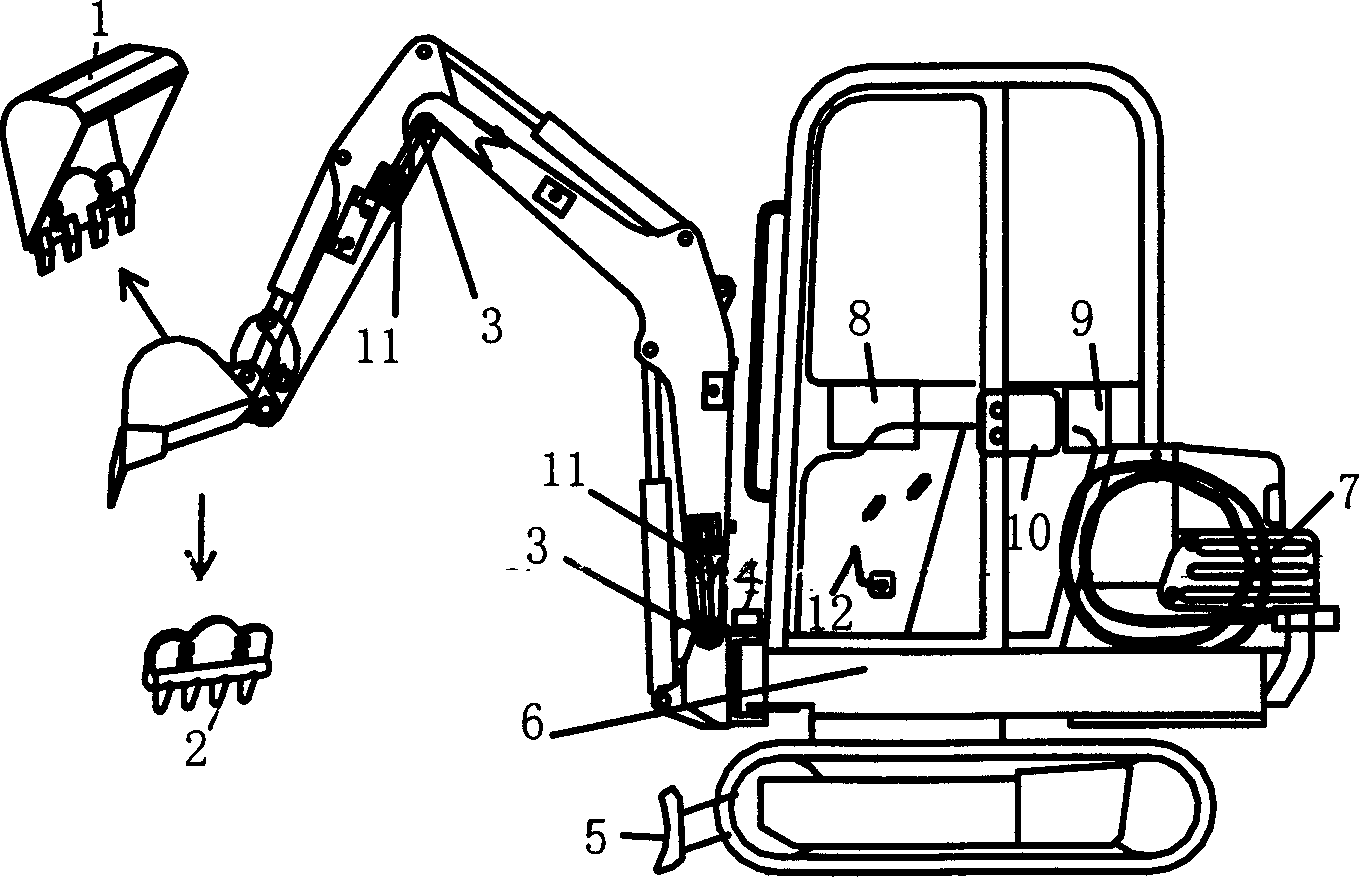

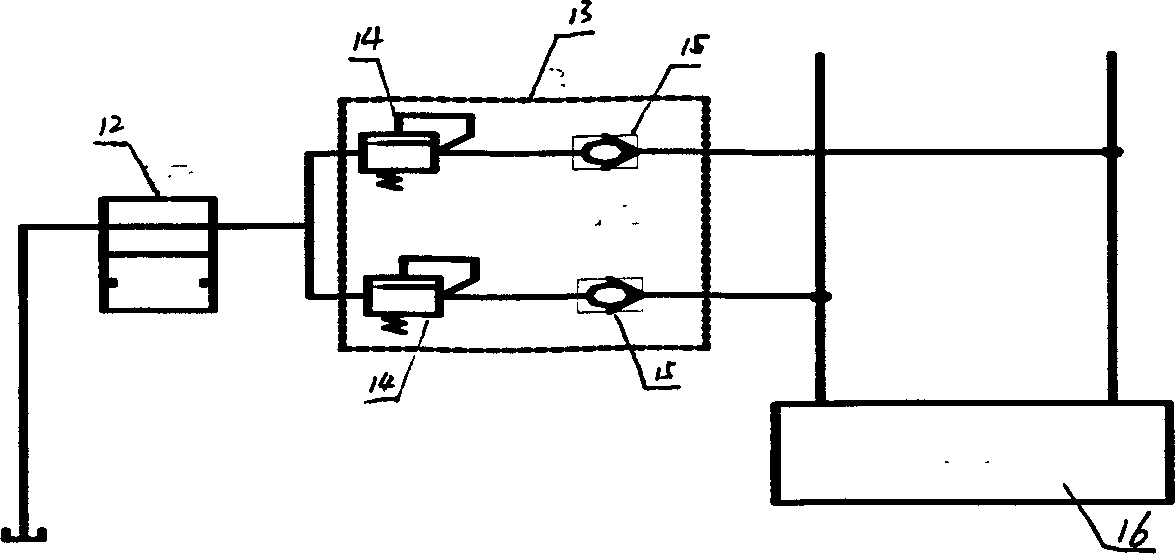

[0040] Reference attached Figure 1~6 , The pipeline safety excavation system includes an excavator, a special precision excavation blunt tooth, a pressure regulating device, a safety excavation sounding alarm device, and a high-pressure jet device.

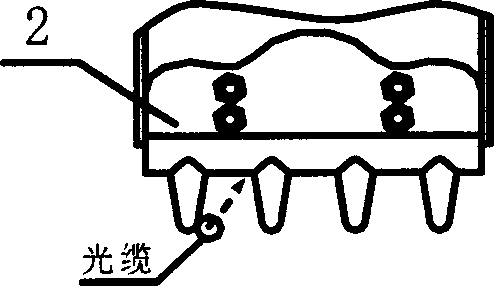

[0041] The special bucket 1 is installed on the forearm of the excavator's arm, and the blunt teeth are excavated. 2 The excavator's bucket is equipped with an angle sensor 3 on the excavator's arm shaft, and a level sensor 4 is installed on the excavator's arm. On the underframe platform, the bulldozing device 5 is installed on the front of the excavator chassis, the jet cylinder 6 is installed on the side of the excavator, the jet pipe 7 is on the side of the excavator, and the excavator operating room is equipped with a depth sounding controller 8. The connector 9, the jet controller 10, the switching valve 11, and the manipulator 11 are fixed on the excavating arm of the excavator.

[0042] The excavator bucket is equipped with sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com