Construction method for river crossing pipeline

A construction method, technology for crossing rivers, applied in the direction of laying and repairing pipes, pipes/fittings/fittings, machinery and equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

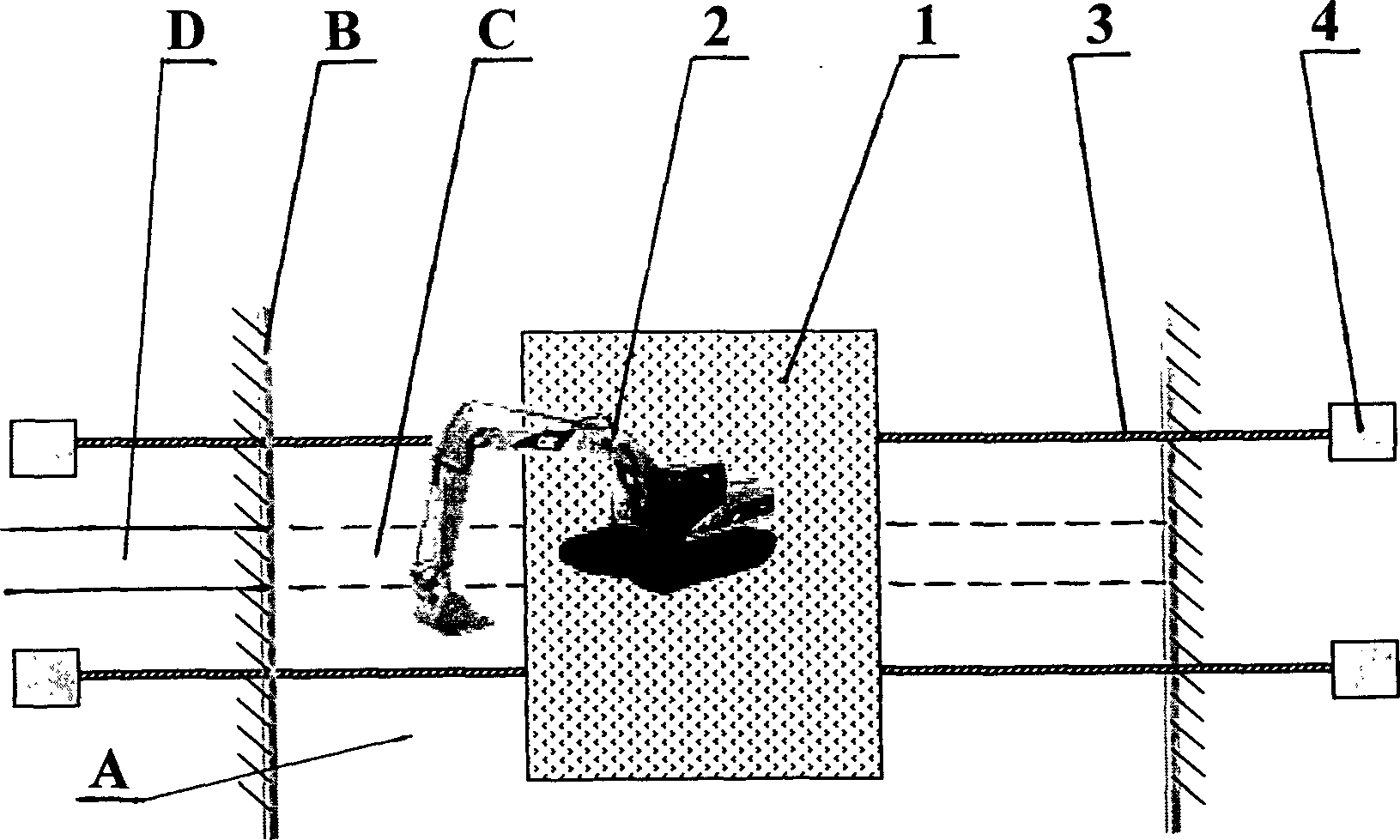

[0014] An embodiment is described with reference to the accompanying drawings:

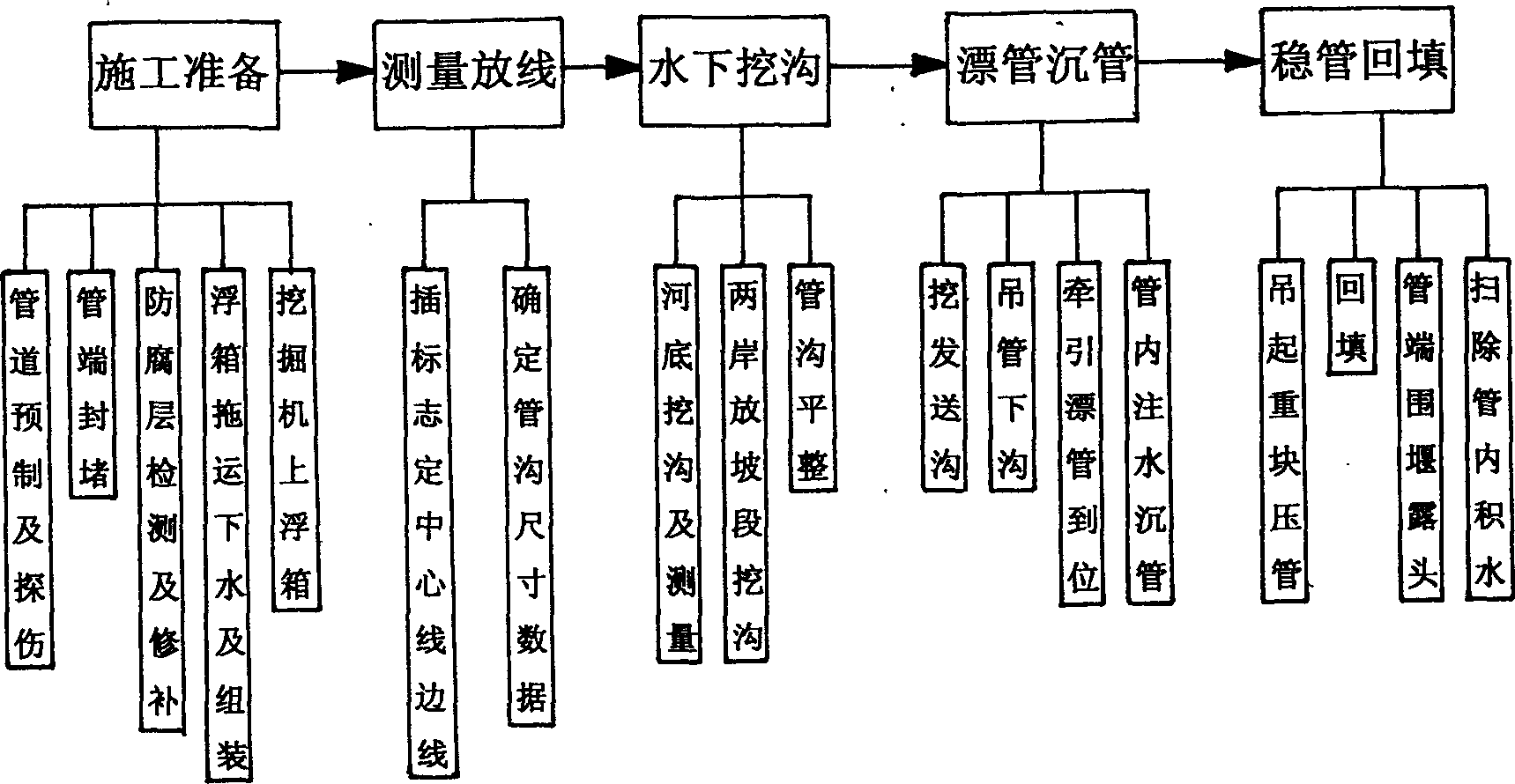

[0015] like figure 1 As shown, the construction procedures of the present invention are: construction preparation, measurement and lay-out, underwater trenching, drifting and sinking, and backfilling of stabilized pipes. The technical content of each process is: the construction preparation process includes pipeline prefabrication and flaw detection, anti-corrosion layer detection and repair, pipe end plugging, floating tank hauling, launching and assembly, and excavator floating tank. The measuring and laying-out process includes inserting marks and flagging the center line and edge line, and determining the dimension data of the pipe trench. The underwater trenching process includes trench trenching and measurement at the bottom of the river, trench trenching at the grading section on both banks, and pipe trench leveling. The process of floating and sinking includes digging and sending ditch, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com