Charged detection method for insulator of high voltage direct current transmission line

A high-voltage direct current, transmission line technology, applied in the direction of measuring current/voltage, measuring electricity, measuring devices, etc., can solve the problems of no live detection, inability to see internal defects and hidden defects of insulators, and inability to use them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

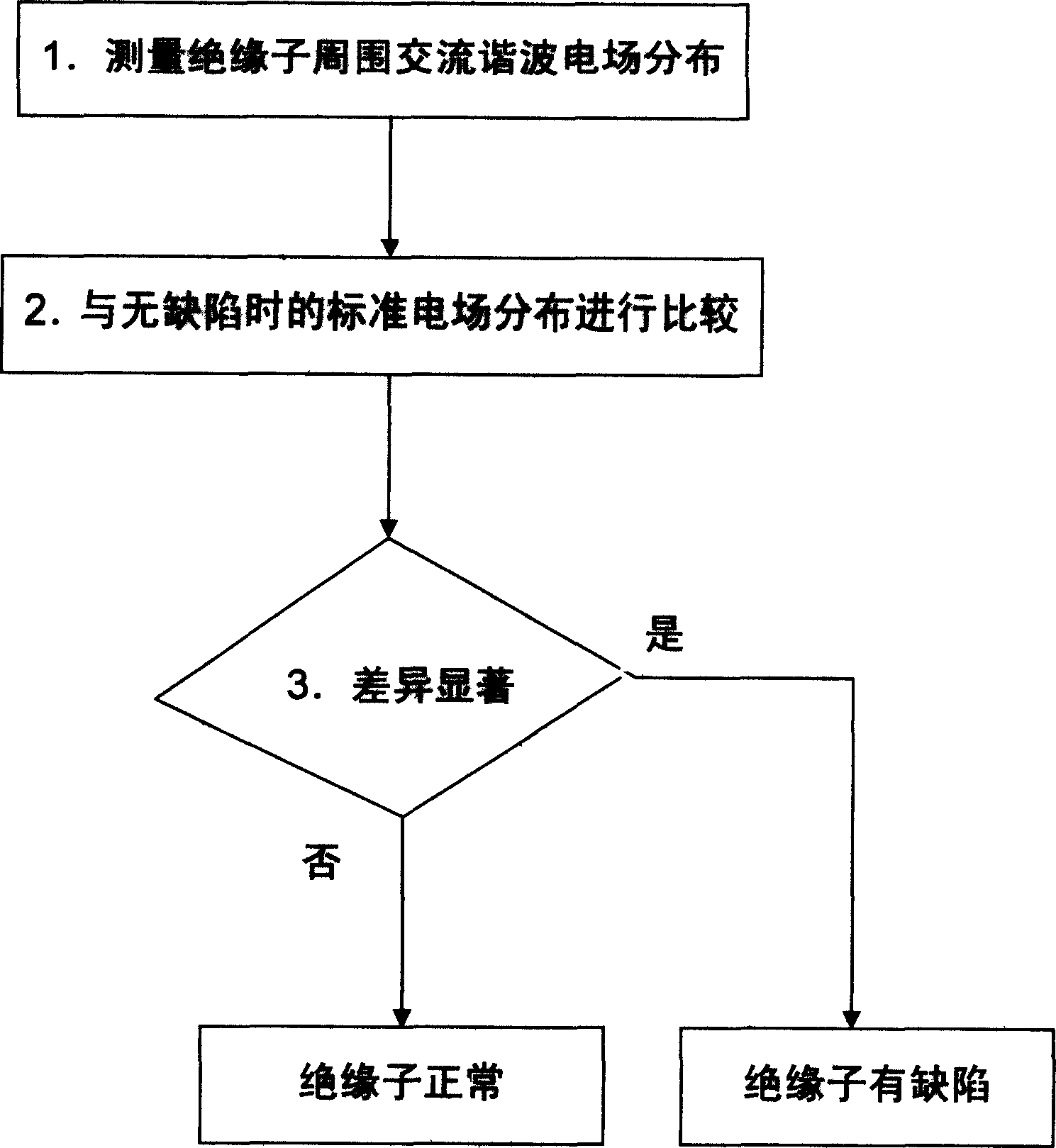

[0010] Embodiment: Referring to the accompanying drawings, a method for live detection of high-voltage direct current transmission line insulators, the steps are:

[0011] (1) Detect the distribution of AC harmonic electric field around the insulator;

[0012] (2) Compare with the standard electric field distribution when there is no defect;

[0013] (3) If there is no significant difference between the two distributions, the insulator is judged to be normal, otherwise it is judged to be defective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com