Measurement error correction method for automobile head light

A technology for measuring errors and headlights, which is used in vehicle maintenance, shunting equipment, vehicle components, etc., and can solve the problems of high misjudgment rate and large automatic detection errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

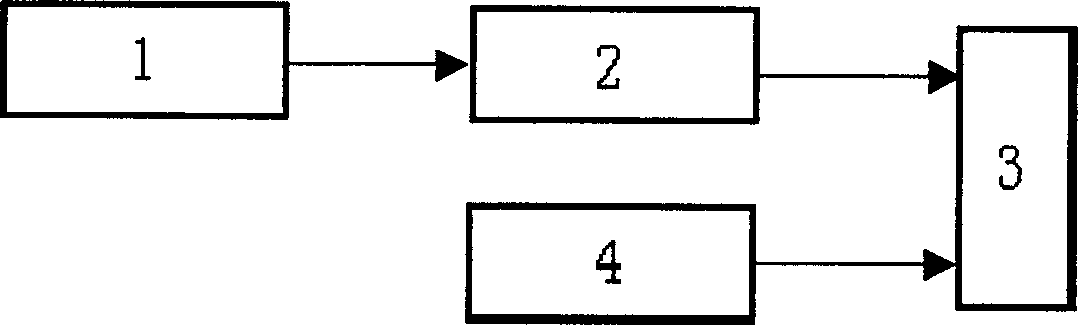

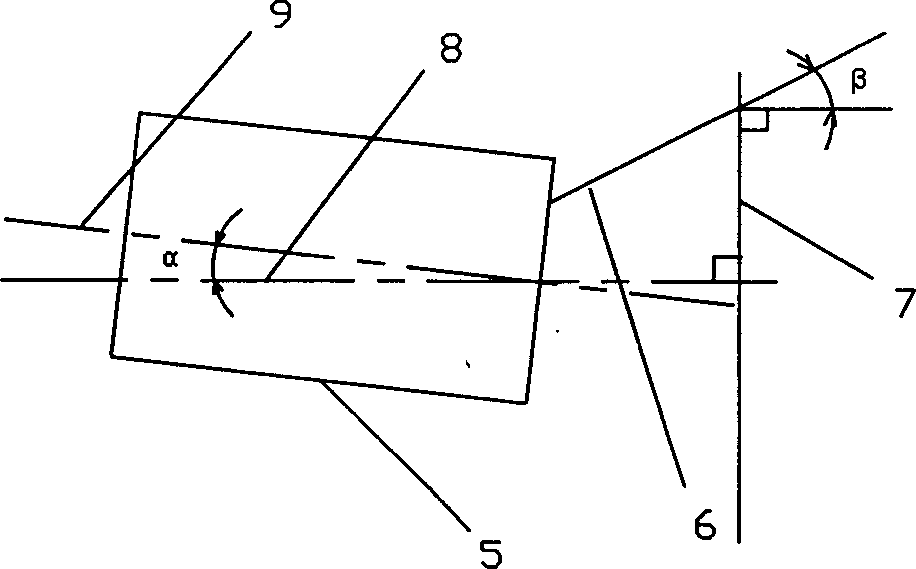

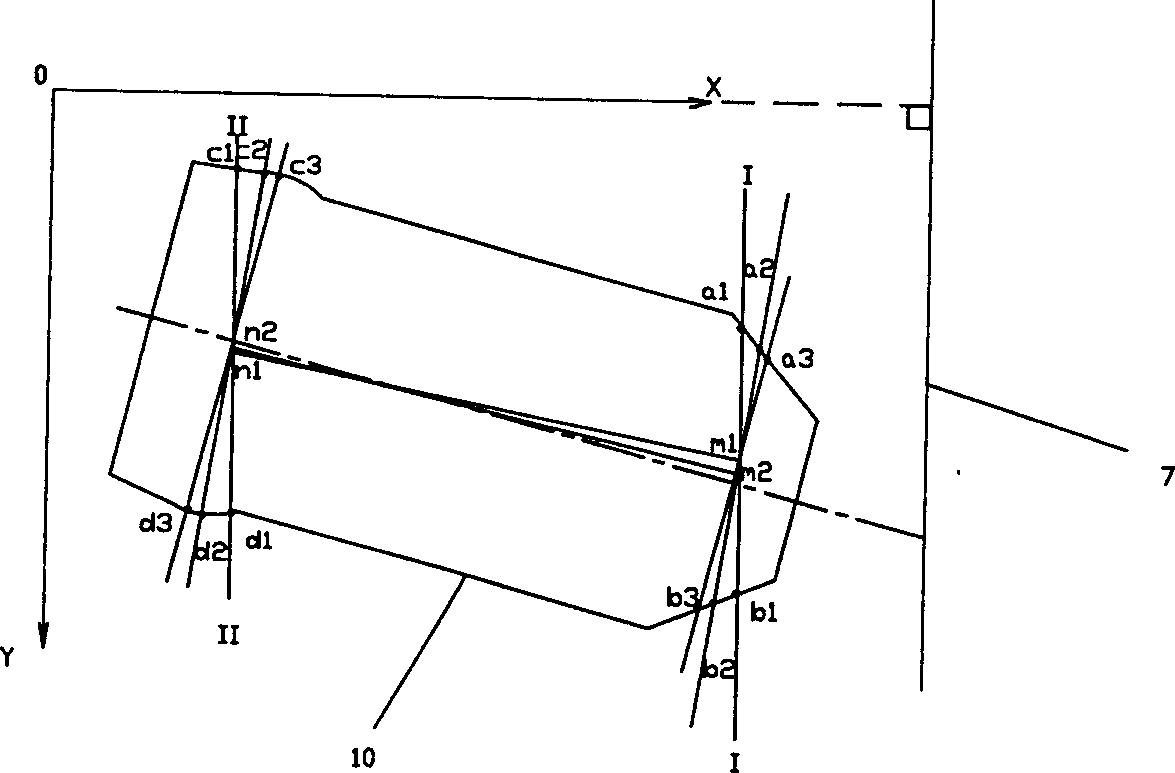

[0035] It is composed of CV-155L black and white CCD camera, PCI-1407 image acquisition card, IBM NetvistaA10 computer and FD-1 headlight detector figure 1 The measurement correction system shown in the figure, in which the CCD camera is installed above the headlight detection station car, 3m above the ground, the computer processing program is as follows Figure 4 . According to the current automobile headlight inspection standard, the system is used to measure the azimuth angle of the high beam horizontal illumination of the left headlight of an ordinary Santana car 10 times. The measurement results and error correction results are as follows:

[0036] Detector indication value β

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com