Plasma display

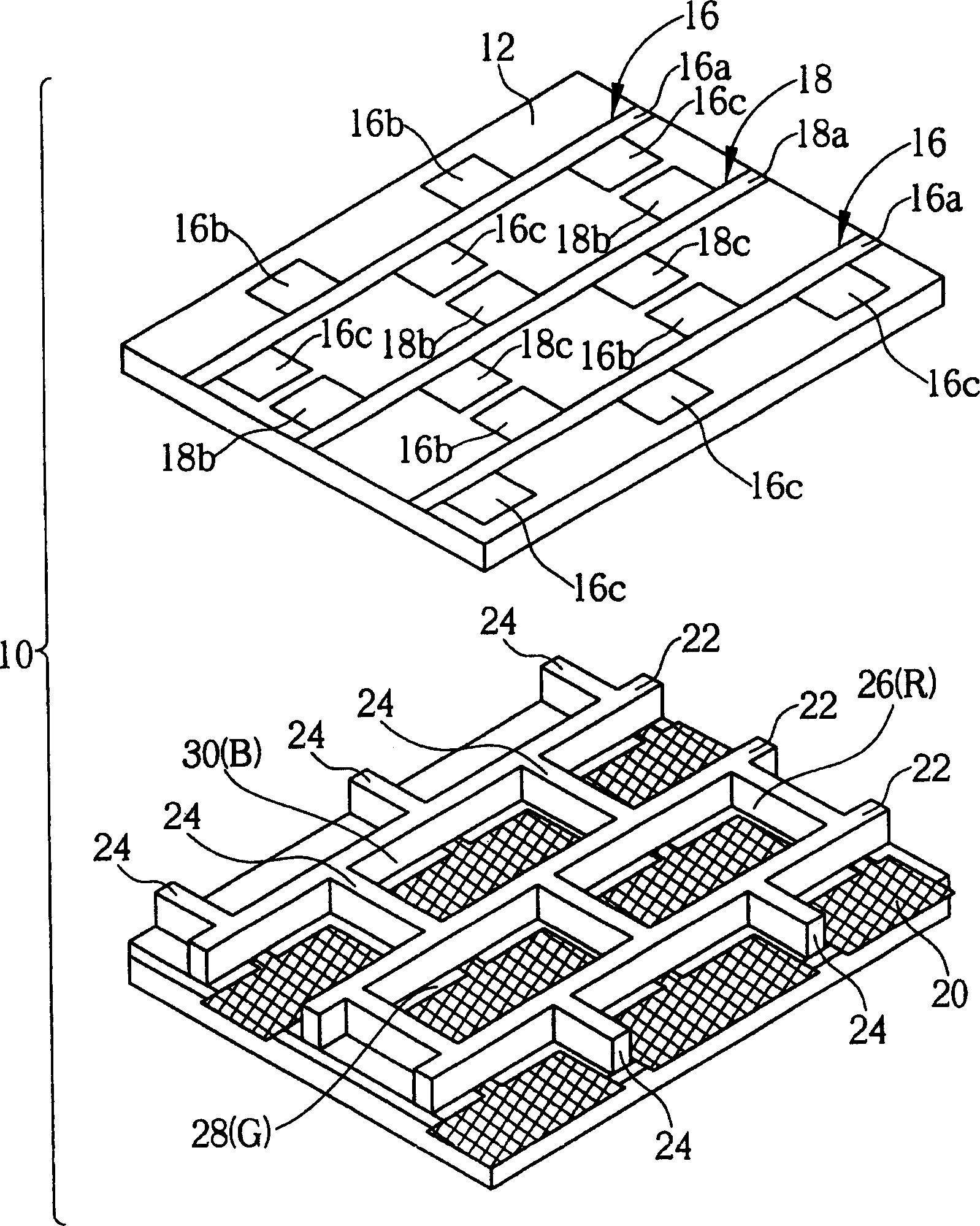

A plasma display, grid-like technology, applied in the direction of cold cathode tubes, etc., can solve the problems of high discharge gas discharge voltage, increasing the operating voltage and power consumption of the plasma display 10, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

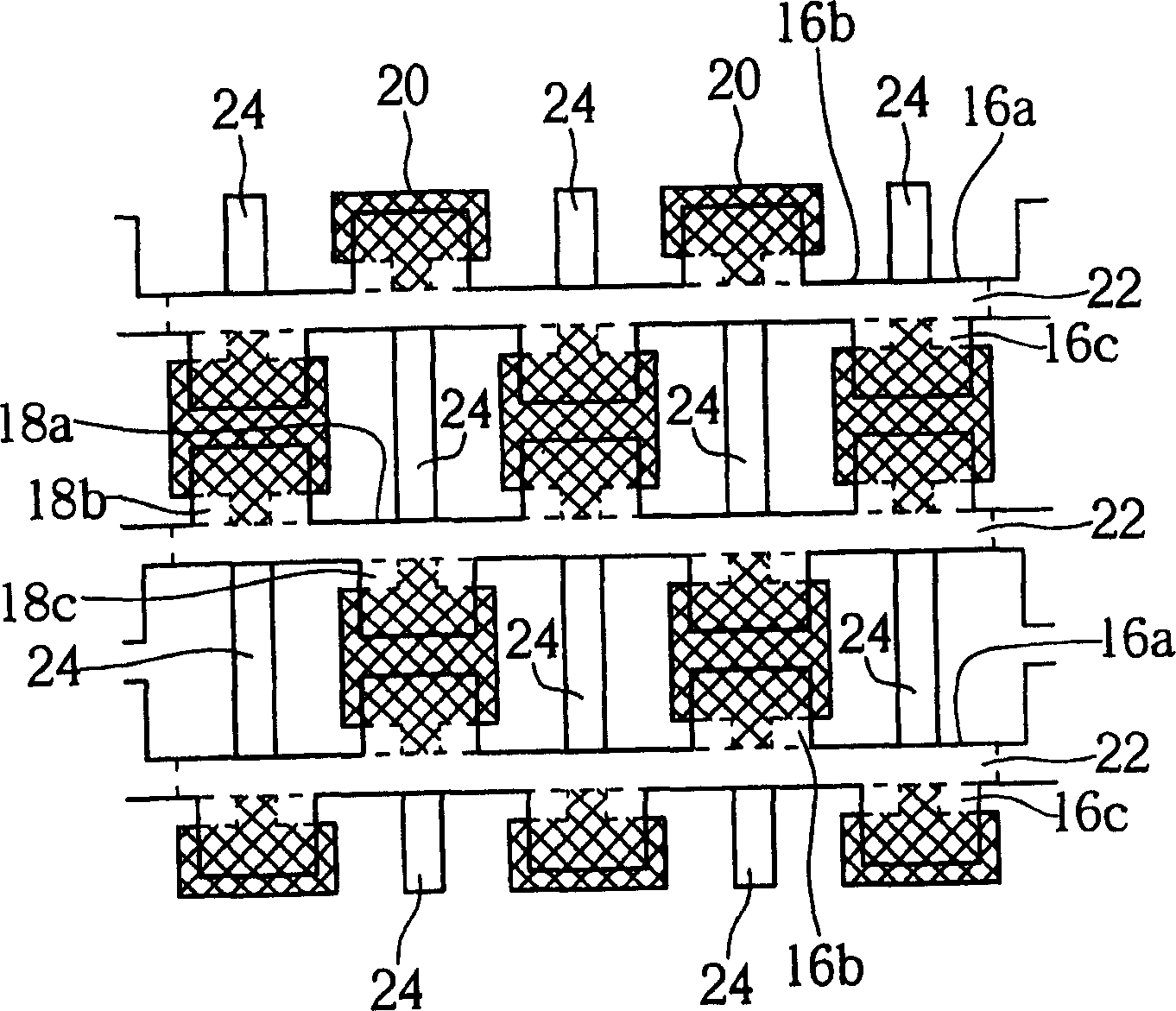

Examples

Embodiment Construction

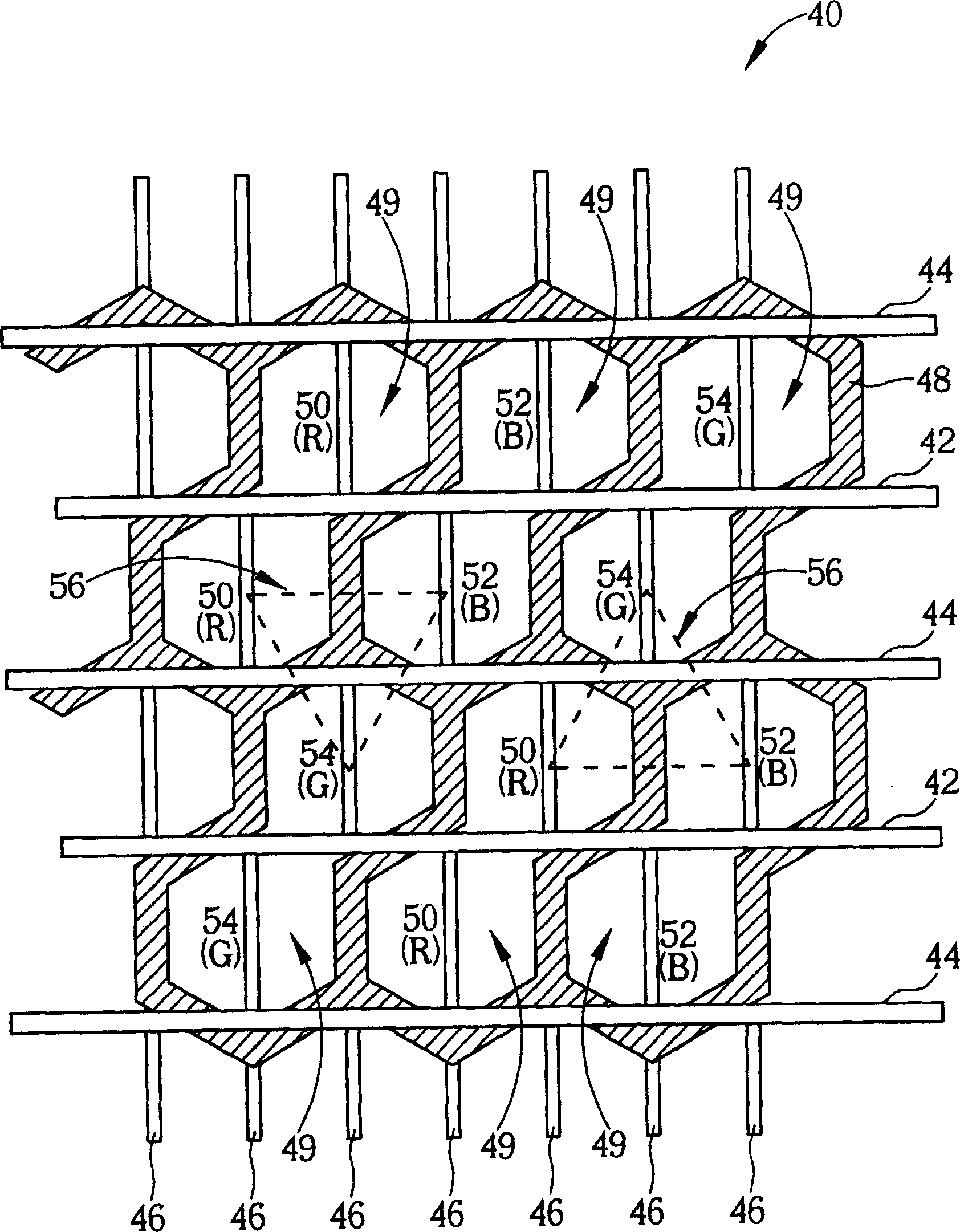

[0051] Please refer to Figure 3 to Figure 5 , Figure 3 to Figure 5 is a top view of the plasma display according to the first embodiment of the present invention, Figure 4 for image 3 A schematic diagram of a closed barrier wall unit is shown. like image 3 As shown, the plasma display 40 includes a front substrate (not shown), a rear substrate (not shown) parallel to and opposite to the front substrate, and a discharge gas (not shown) filled between the front substrate and the rear substrate. In addition, the plasma display 40 also includes a plurality of X electrodes 42, a plurality of Y electrodes 44, and a plurality of address electrodes 46 perpendicular to each X electrode 42 and each Y electrode 44, wherein each X electrode 42 and each Y electrode 44 All of them are arranged in parallel and staggered on the surface of the front substrate, and the address electrodes 46 are arranged in parallel on the surface of the rear substrate. In general, each X electrode 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com