Plane light-source and mfg. method

A manufacturing method and technology for flat lamps, which are applied in the manufacture of discharge tubes/lamps, cold cathodes, electrode systems, etc., can solve the problems of unfavorable flat light source 100 output, cumbersomeness, increase, etc., so as to save space and increase output. , the effect of simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

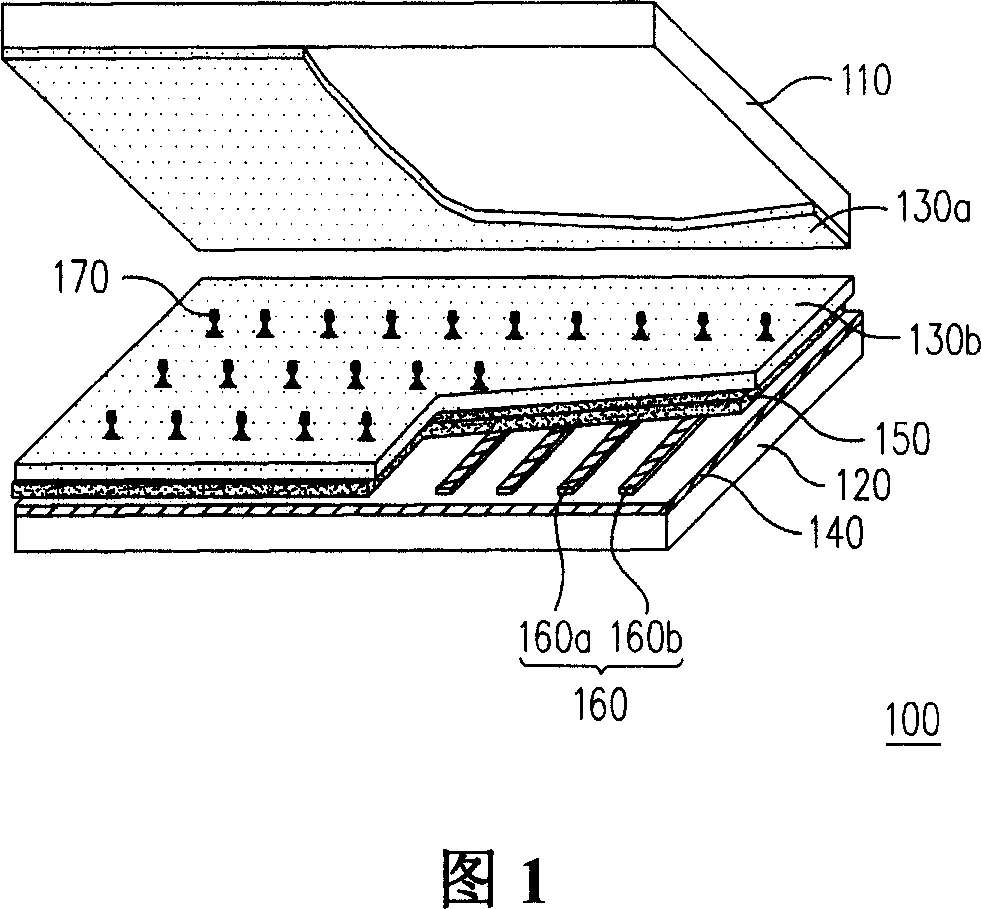

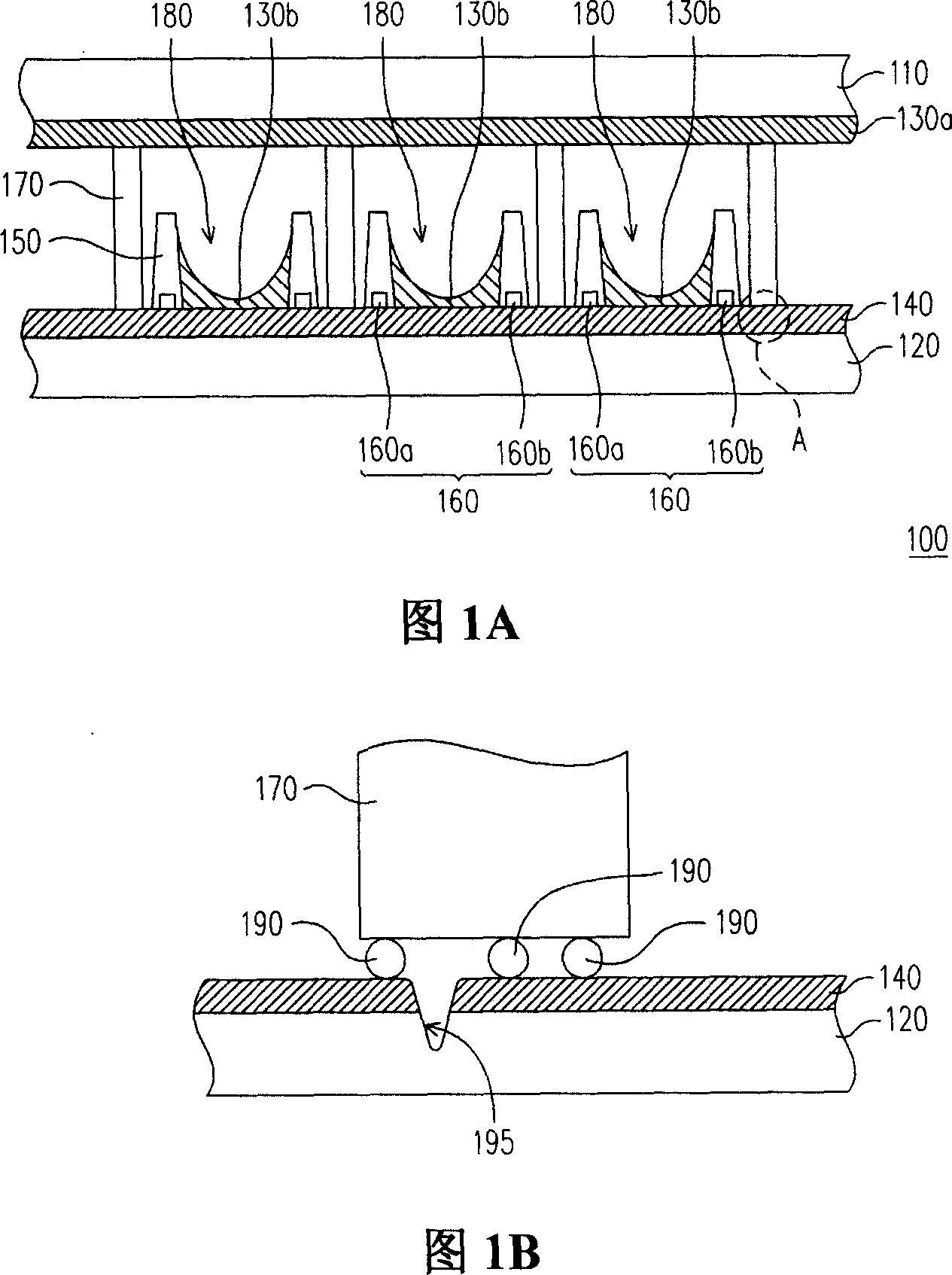

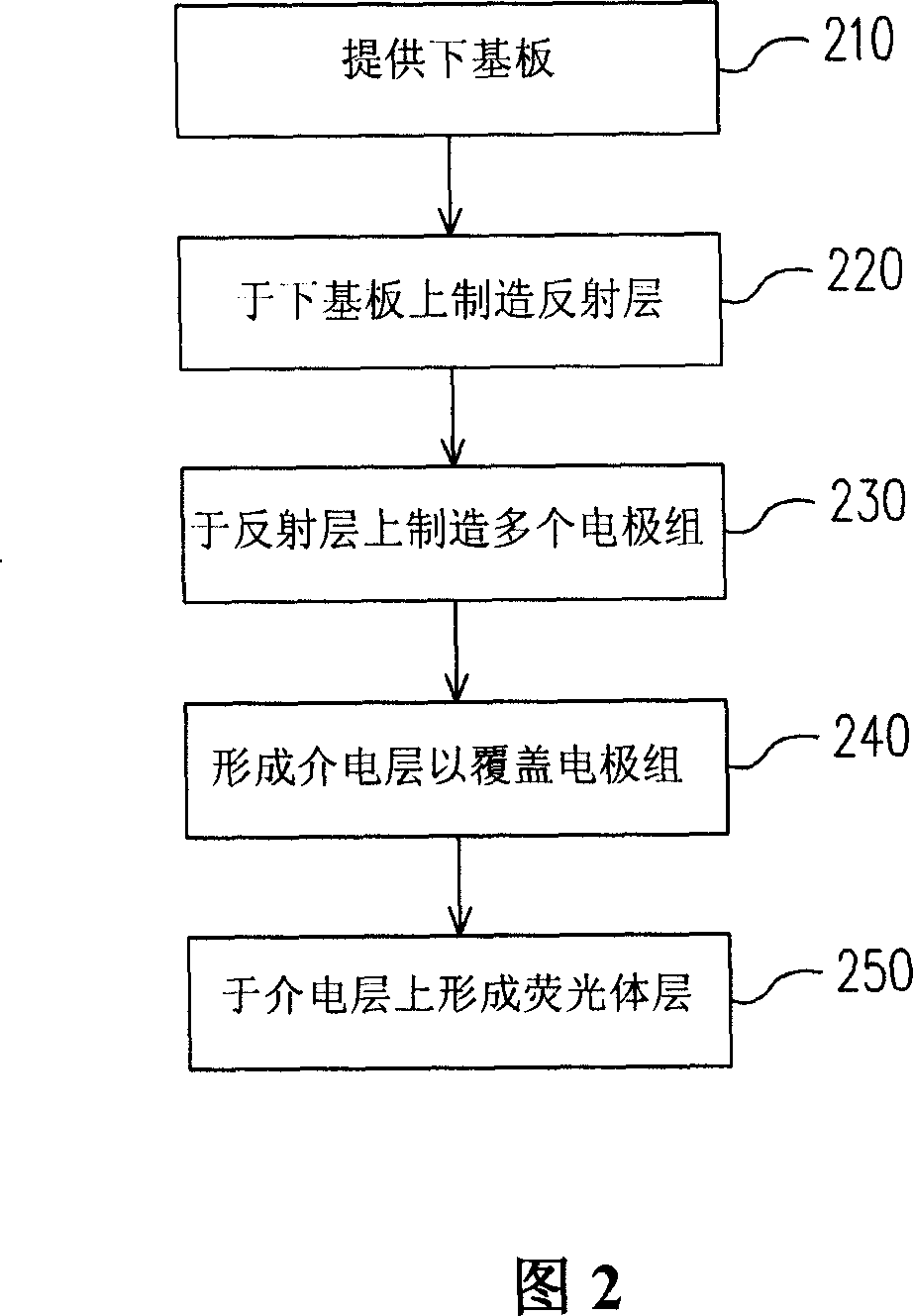

[0064] Fig. 3 is a schematic diagram of a planar light source in a preferred embodiment of the present invention. Referring to FIG. 3 , the planar light source 300 includes a first substrate 310 , a plurality of electrode groups 320 , a second substrate 330 , a dielectric spacer 340 , a phosphor layer 350 and a discharge gas 360 . The electrode group 320 is disposed on the first substrate 310 . The second substrate 330 is disposed above the first substrate 310 . The dielectric spacer 340 covers the electrode group 320, and the dielectric spacer 340 is connected between the first substrate 310 and the second substrate 330, and the dielectric spacer 340 divides the space between the first substrate 310 and the second substrate 330 It is divided into a plurality of discharge spaces 370 . The phosphor layer 350 is disposed in the discharge space 370 . The discharge gas 360 is disposed in the discharge space 370 .

[0065] Please continue to refer to FIG. 3 , in one embodiment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com