Liquid surface suspension pressurization control method for low-pressure casting machine

A technology of low-pressure casting machine and control method, which is applied in the field of low-pressure casting, and can solve the problems of affecting the internal quality of castings, scouring of riser pipes, and reducing the life of riser pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

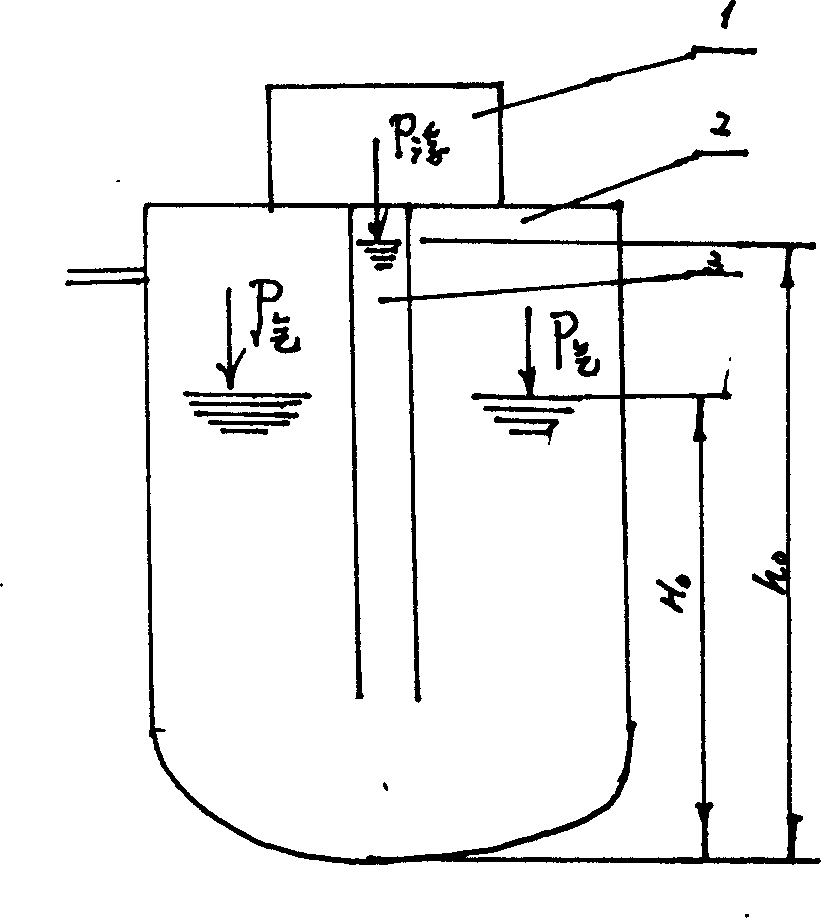

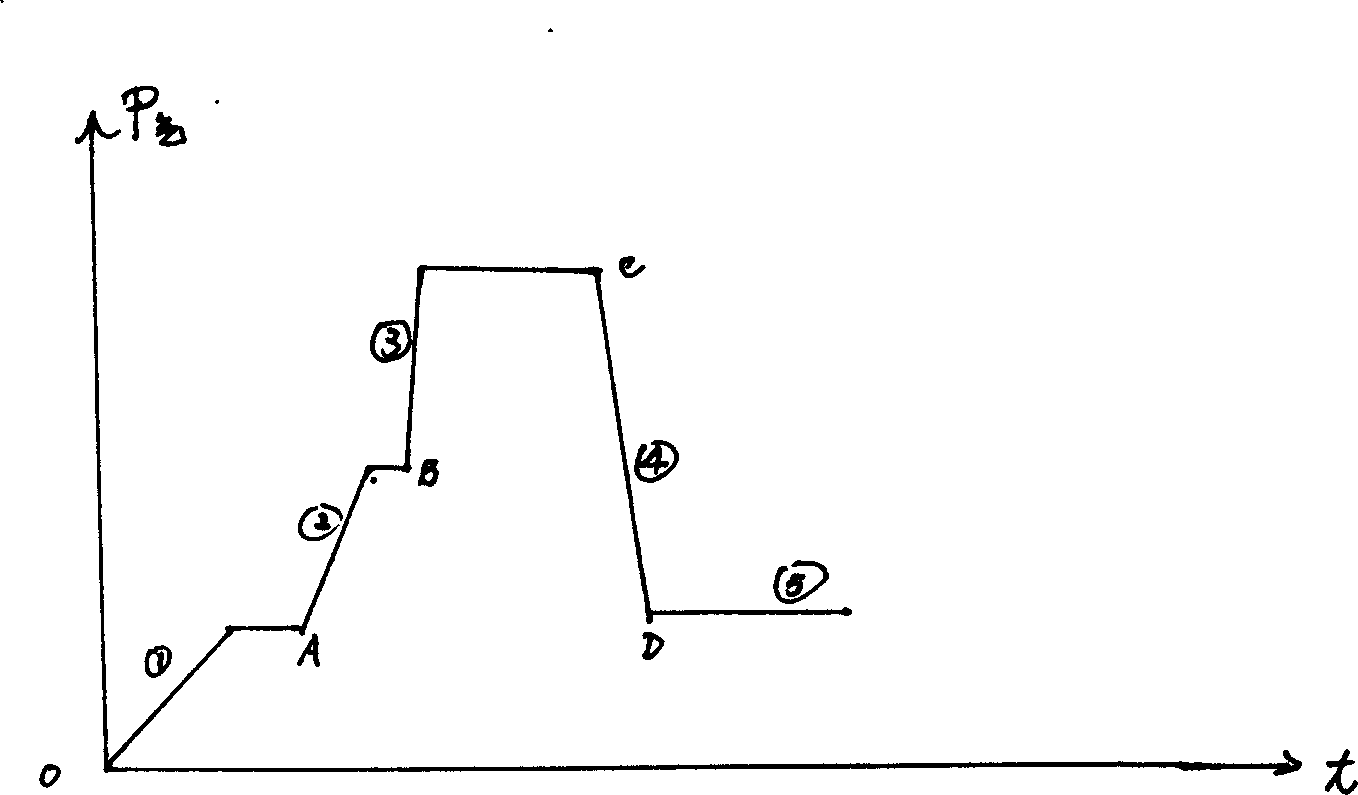

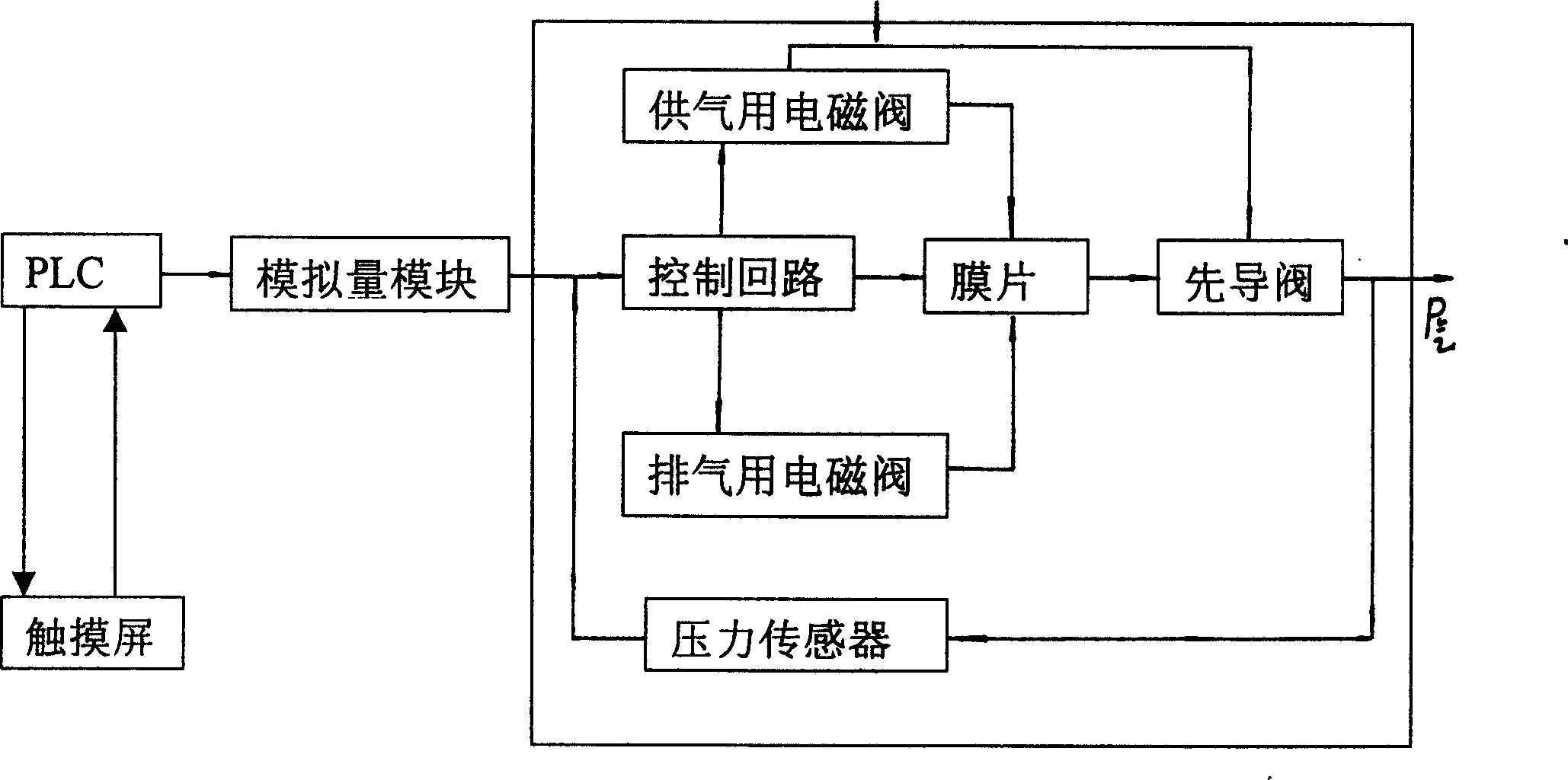

[0018] a. Confirm the initial value: determine a certain set suspension level height h in the riser 0 The corresponding pressure P 气 value;

[0019] b. Storage: the P that will be obtained 气 The initial value is stored in the programmable controller PLC as a reference value;

[0020] c. Set the compensation amount: PLC according to the crucible cross-sectional area S provided 坩 , the specific gravity of liquid metal γ, and the rough weight of the processed parts mg, calculate the pressure compensation coefficient ΔH between two castings:

[0021]

[0022] The compensation coefficient calculates the pressure compensation amount ΔP between two pours through the program set in the PLC, and stores it in memory; then, according to the low-pressure pouring control program set in the PLC, it compensates for each low-pressure pouring process;

[0023] d. After completing the pressure boosting and pressure maintaining process in the low-pressure pouring process, the pressure rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com