Oil-free lubrication whirlpool compressor

A scroll compressor and oil-free lubrication technology, applied in the field of scroll compressors, can solve problems such as limiting the application field of scroll compressors, affecting the normal operation of other equipment, and complicating the oil supply system of compressors, achieving simple structure, The effect of clean compression and simple oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

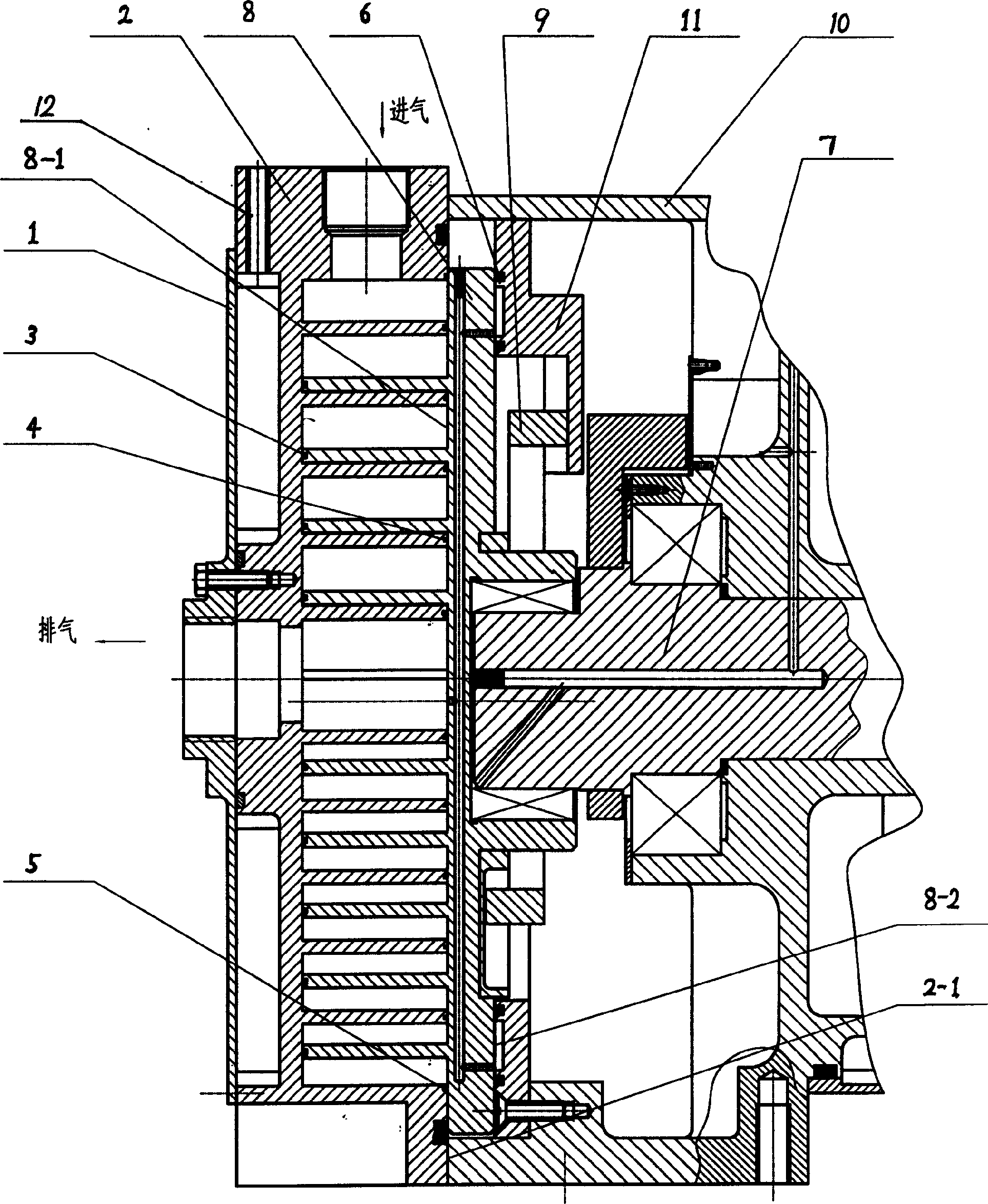

[0008] figure 1 It is an assembly structure diagram of the present invention, and the structure on the right side of the rotating shaft (7) is the same as the prior art, and is not marked in the figure. like figure 1 As shown, the spiral teeth on the orbiting scroll (8) intersect with the spiral teeth on the stationary scroll (2), thereby defining a plurality of moving fluid chambers, and the crankshaft (7) is rotatably supported by bearings, driving The orbiting scroll (8) performs orbital motion relative to the stationary scroll (2). The anti-rotation mechanism is composed of the orbiting scroll (8) and the Oldham coupling (9). A sealing strip (3) made of self-lubricating material is installed on the bottom plate of the scroll tooth top and the stationary scroll (2), and the scroll tooth top of the stationary scroll (2) and the orbiting scroll ( 8) A sealing strip (4) made of self-lubricating material is installed on the bottom plate, and an annular sealing strip (5) is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap