Discharge lamp with phosphor

A technology for luminescent substances and discharge lamps, which is applied in the direction of discharge lamps, components of gas discharge lamps, luminescent materials, etc., and can solve problems such as damage to blue luminescent components, differential quantum efficiency, and loss of luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

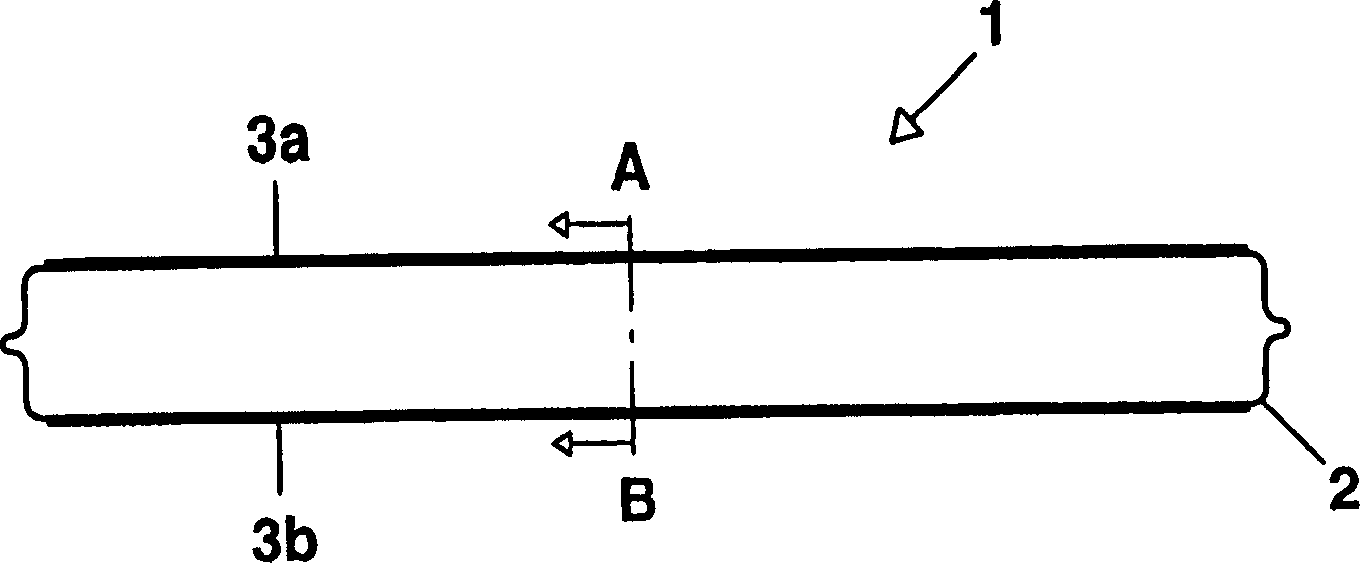

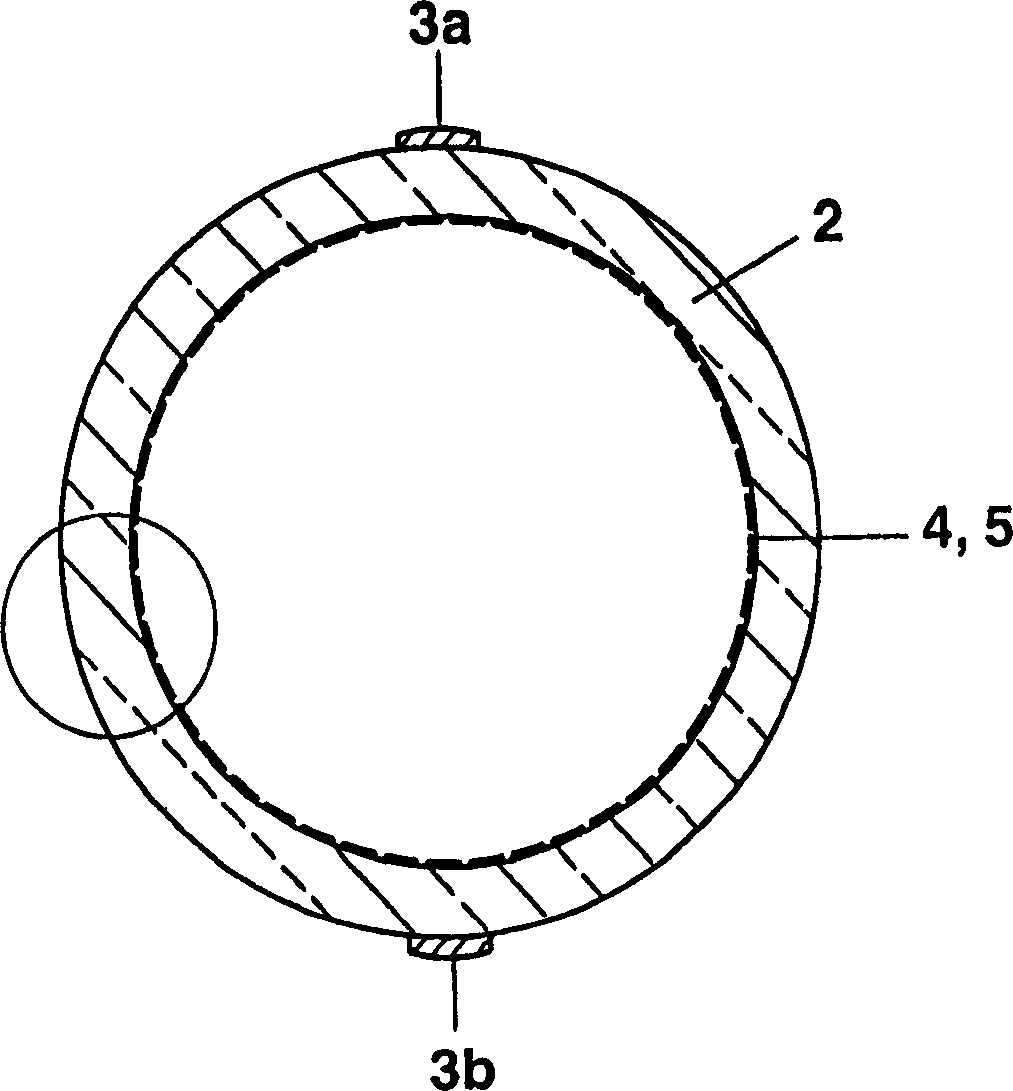

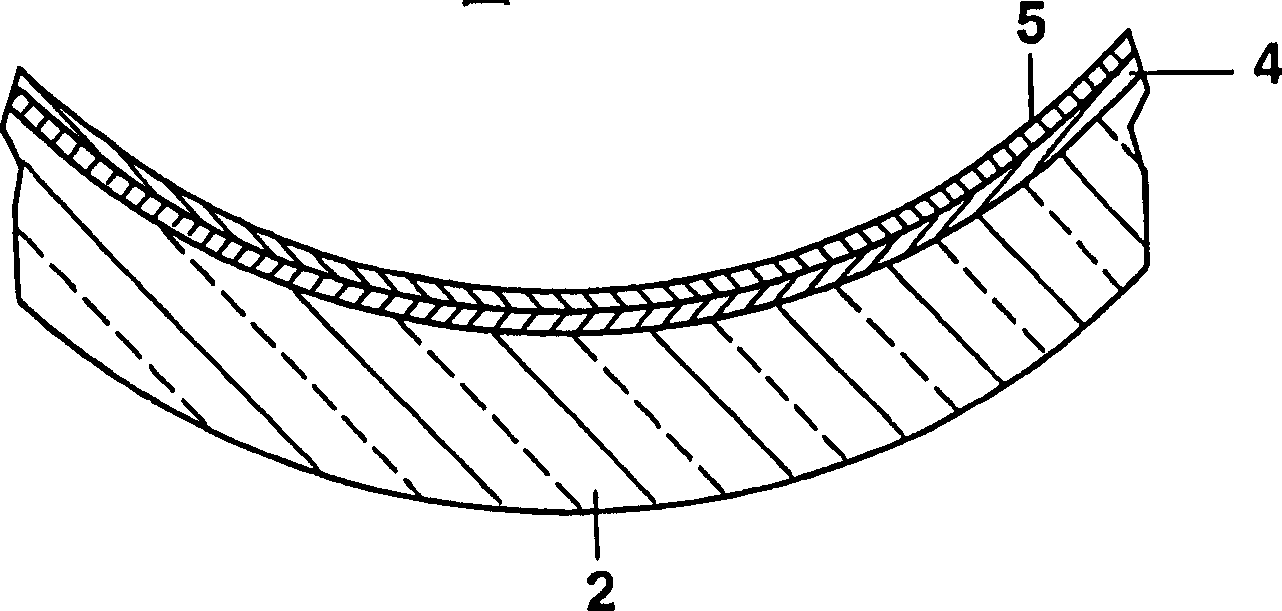

[0071] Refer below Figure 1a~1c A preferred embodiment of the present invention is illustrated.

[0072] The discharge lamp 1 has a tubular discharge vessel 2 with an outer diameter of approximately 10 mm, which is sealed at both ends. The discharge vessel 2 is made of soda lime glass and is filled with xenon at a pressure of about 15 kPa as a discharge medium. On the outer side of the wall of the discharge vessel 2 are applied two metal electrodes 3a, 3b formed as linear conductors which lie diametrically opposite and parallel to the longitudinal axis of the discharge vessel. On the inner side of the wall of the discharge vessel 2, an "inner" luminescent substance layer 4 and an "outer" luminescent substance layer 5 are applied. With respect to the "outside" of the discharge medium, the first luminescent substance layer 5 is composed of UVA components Ce 0.99 Ba 0.01 MgAl 11 o 18.99 composition with a layer weight of 1.8 mg / cm 2 . The "outside" second luminescent mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com