Turnover spring for button switch and button switch using the same

A switch and button technology, applied in the field of button switch structure, can solve the problems of cost increase, mold manufacturing and forming complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

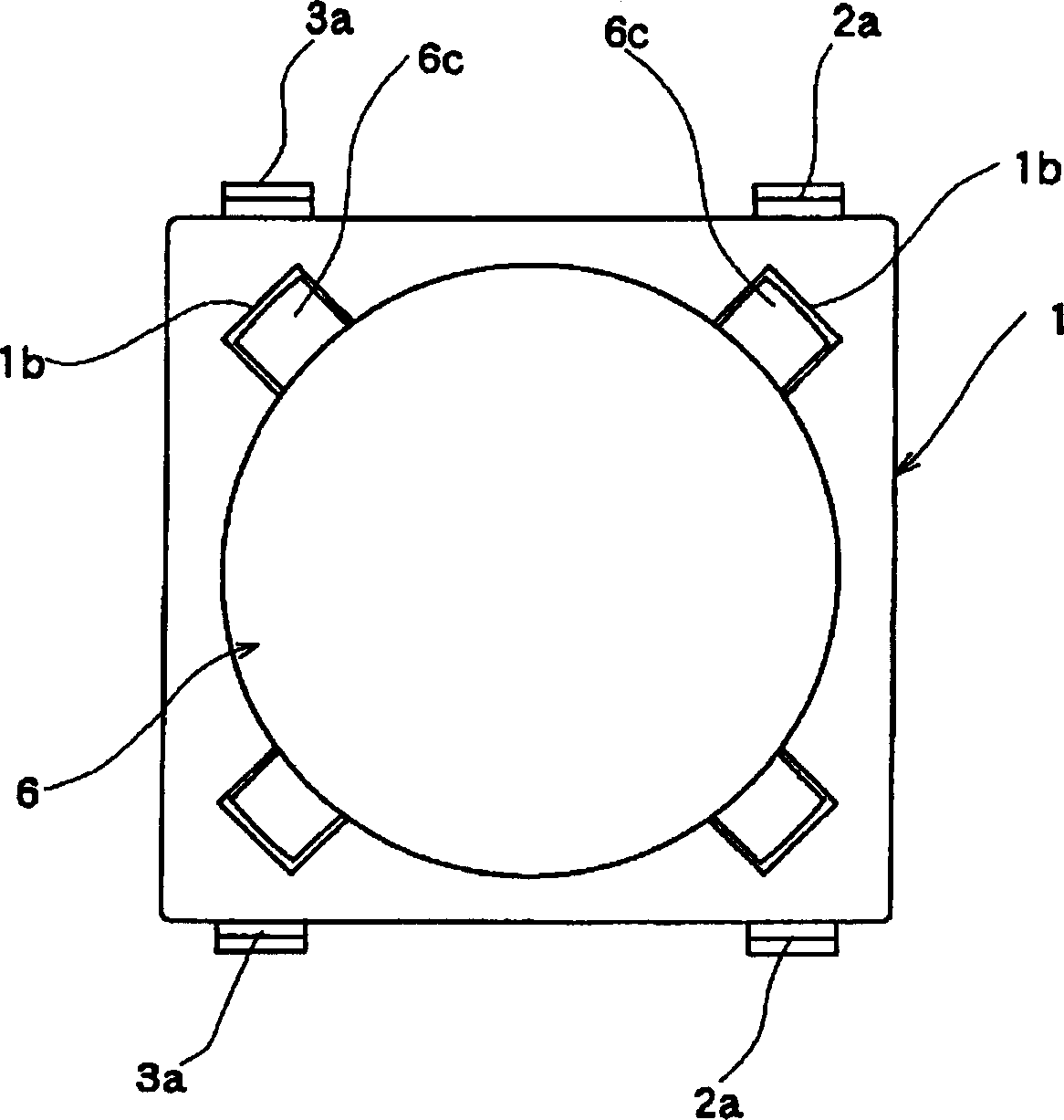

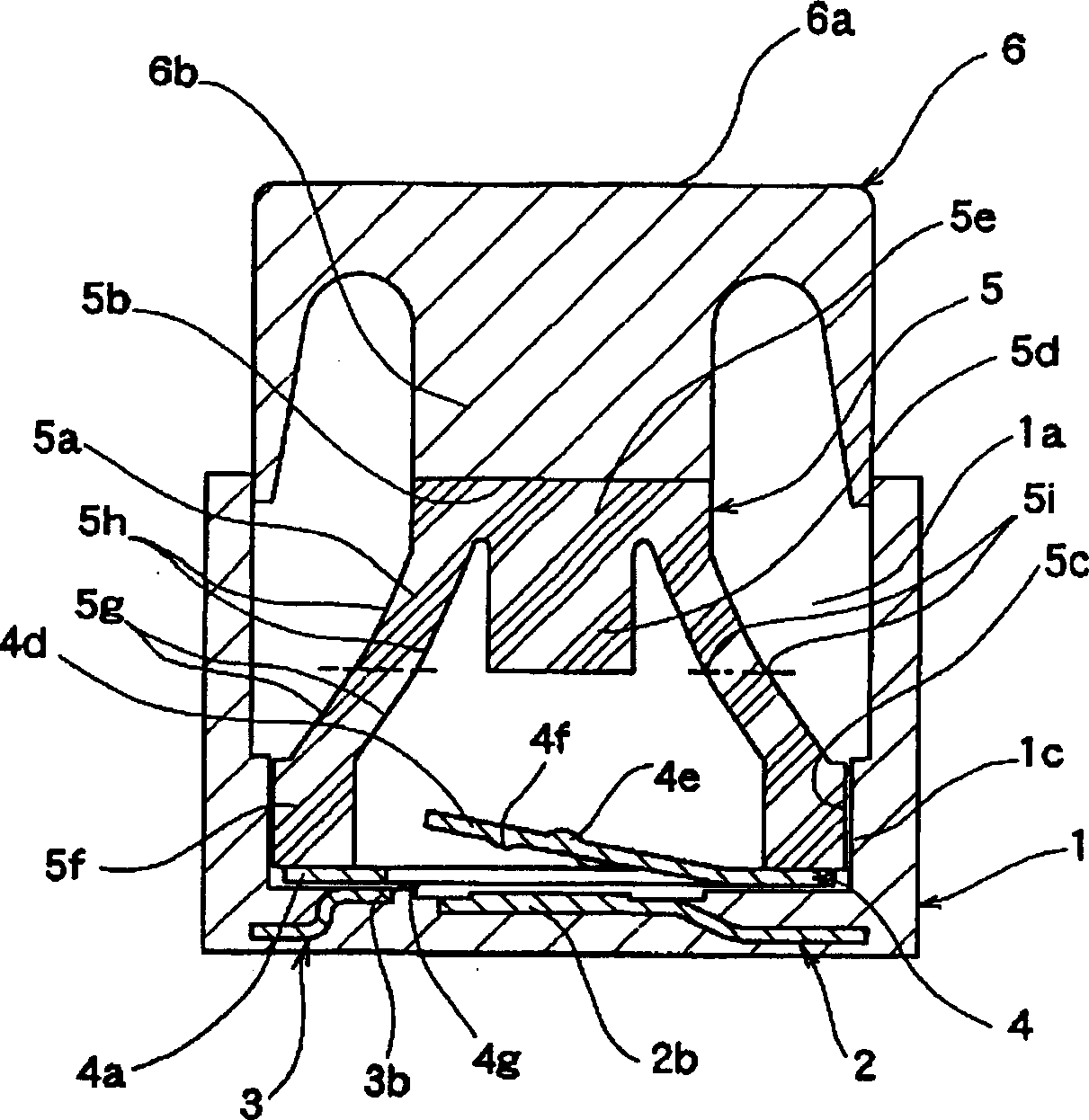

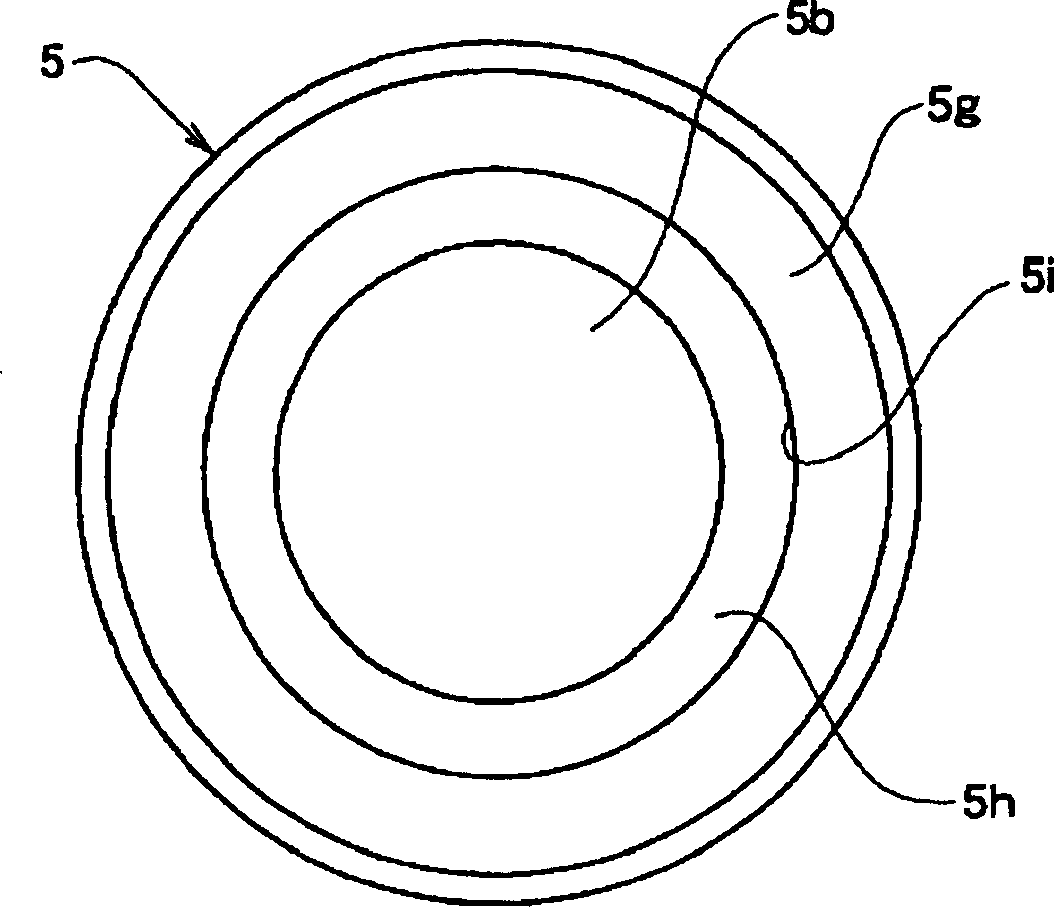

[0026] Use the following Figure 1 to Figure 5 , an embodiment of the flip spring for the push button switch and the push button switch of the present invention will be described. figure 1 is the top view of the push button switch, figure 2 is a cross-sectional view of a push button switch, image 3 is the top view of the flip spring, Figure 4 is the cross-sectional view of the flip spring, Figure 5 It is an explanatory diagram showing the force characteristic of the reversing spring.

[0027] The case 1 is made of an insulating material such as synthetic resin, and is formed in a rectangular box shape with an open top. In the opening of the housing 1, a receiving portion 1a is formed; the inner bottom of the receiving portion 1a is molded on the above-mentioned pair of fixed contacts 2, 3 formed of conductive metal materials such as brass by insert molding or other methods. on the shell 1, and make it form a whole with the shell 1.

[0028] In addition, guide groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com