Plate-like workpiece dividing apparatus

A workpiece, disc-shaped technology, applied in the direction of fine work equipment, electrical components, manufacturing tools, etc., can solve problems such as easy damage and reduced productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

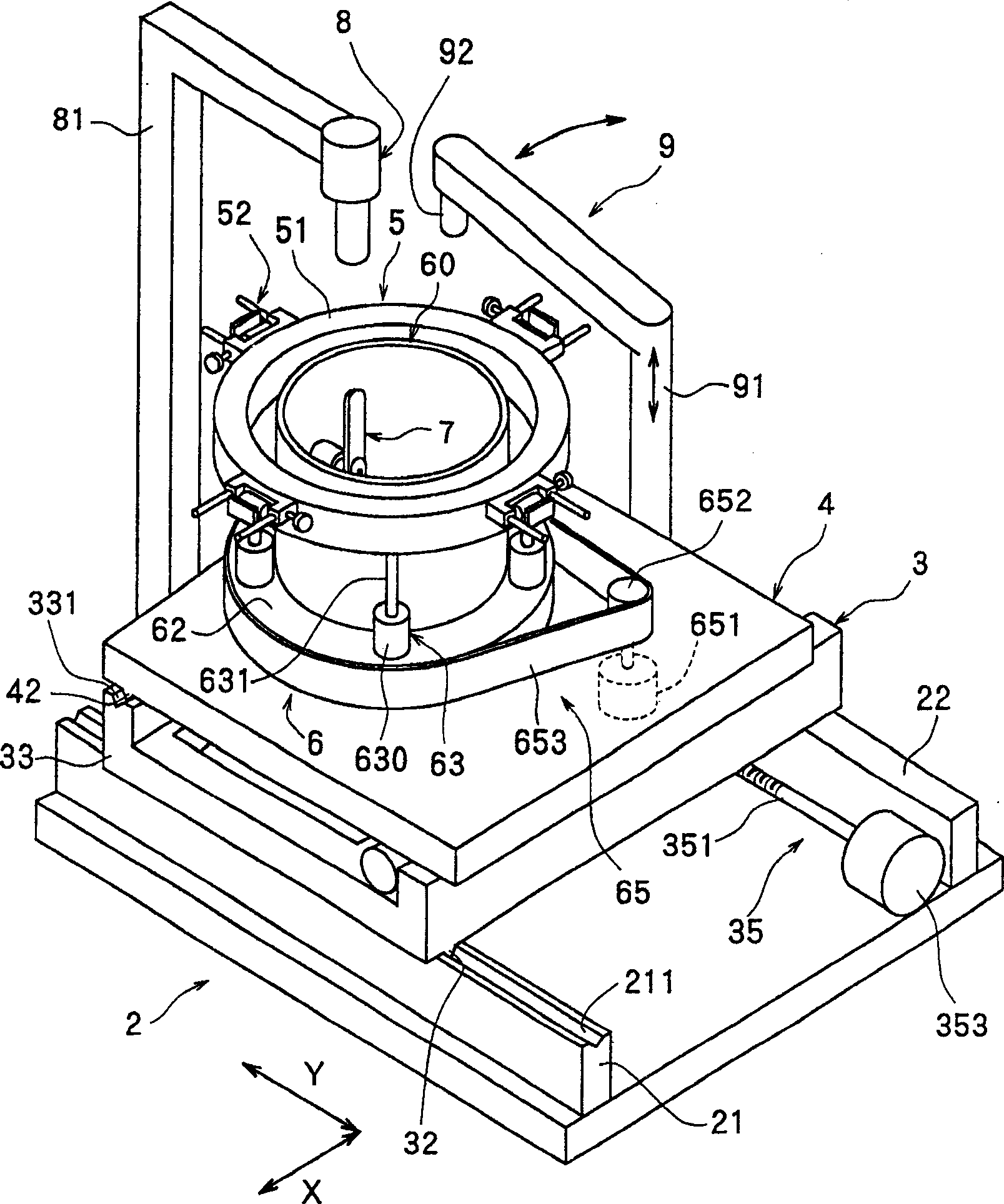

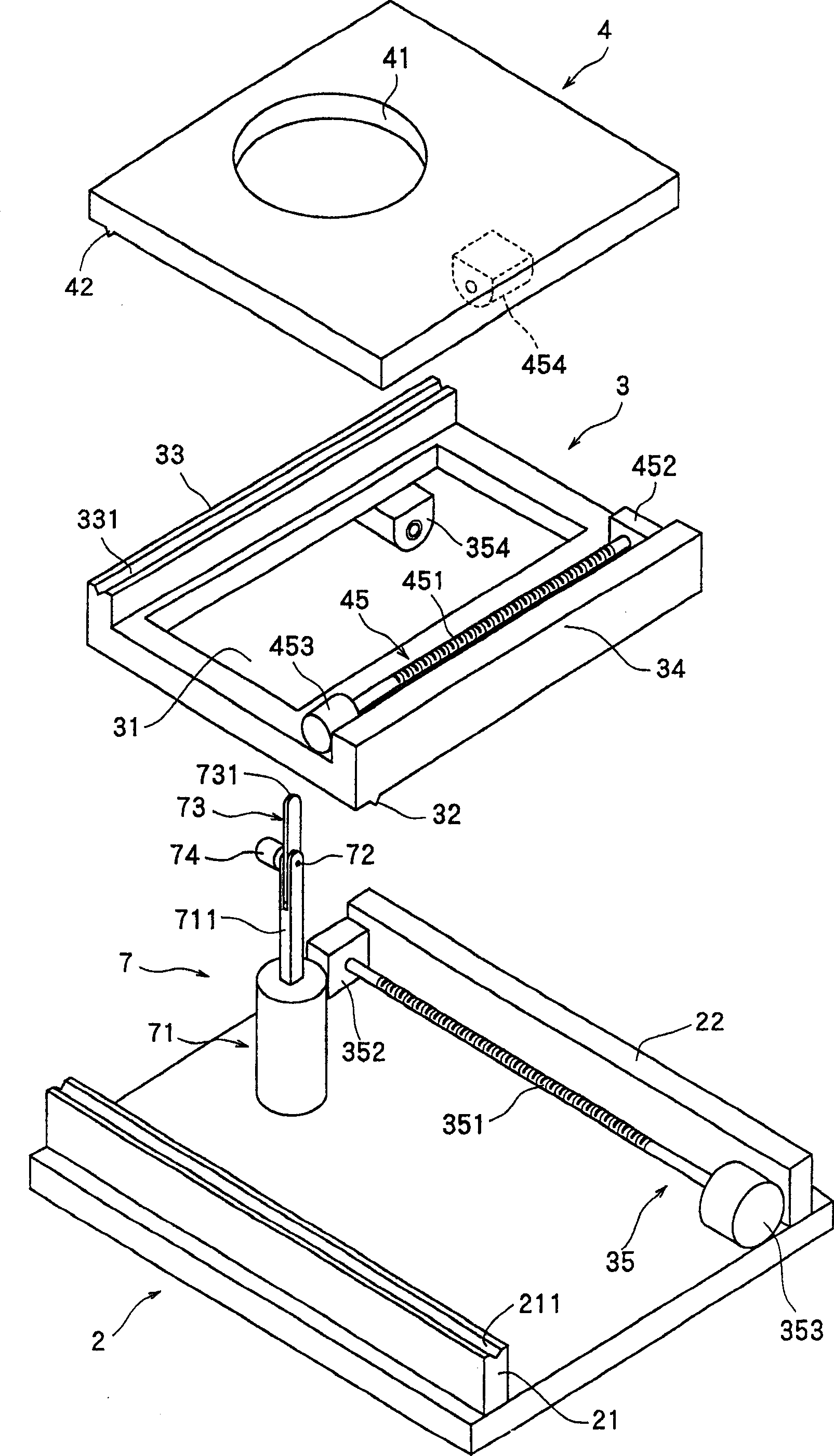

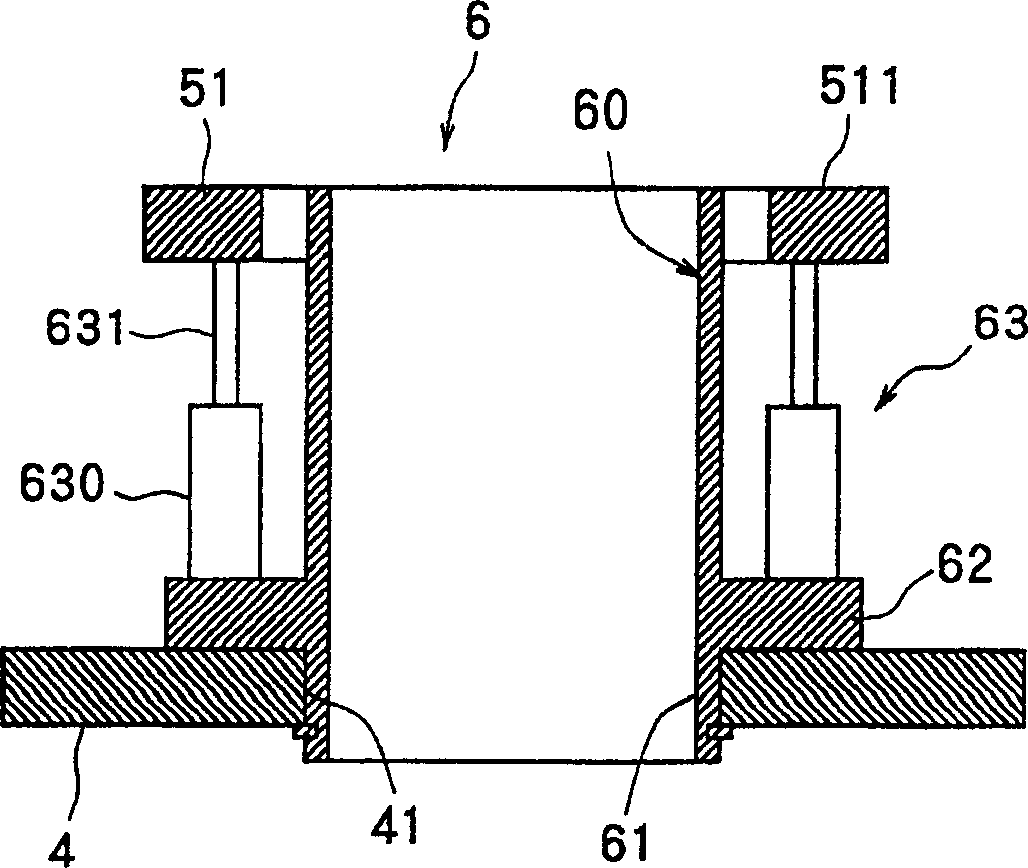

[0029] Preferred embodiments of a disc-shaped workpiece dividing device constructed according to the present invention will be described in detail below with reference to the accompanying drawings.

[0030] In order to split the disk-shaped workpiece whose strength decreases along the splitting line, it is supported on the ring-shaped frame 12 by placing the disk-shaped workpiece 10 face up on the top surface of the protective tape 13 fixed to the ring-shaped frame 12, as Figure 10 shown. Below, see Figure 11 (a) to Figure 11 (c) Describes the step of placing a disk-shaped workpiece whose strength is reduced along the parting line on the top surface of the protective tape 13 fixed to the ring frame 12 .

[0031] The disk-shaped workpiece 10 in the illustrated embodiment is a semiconductor wafer having a plurality of dividing lines 101 formed in a grid pattern on the front surface 10a and circuits formed in a plurality of regions divided by the plurality of dividing lines ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com