Pump system for conveying lubricating oil

A pump system and lubricating oil technology, applied in the field of pump system, can solve the problems of cooling and conveying oil volume, excessive wear of cutting chain, unsatisfactory cutting effect, etc., and achieve the effect of reducing mechanical loss and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

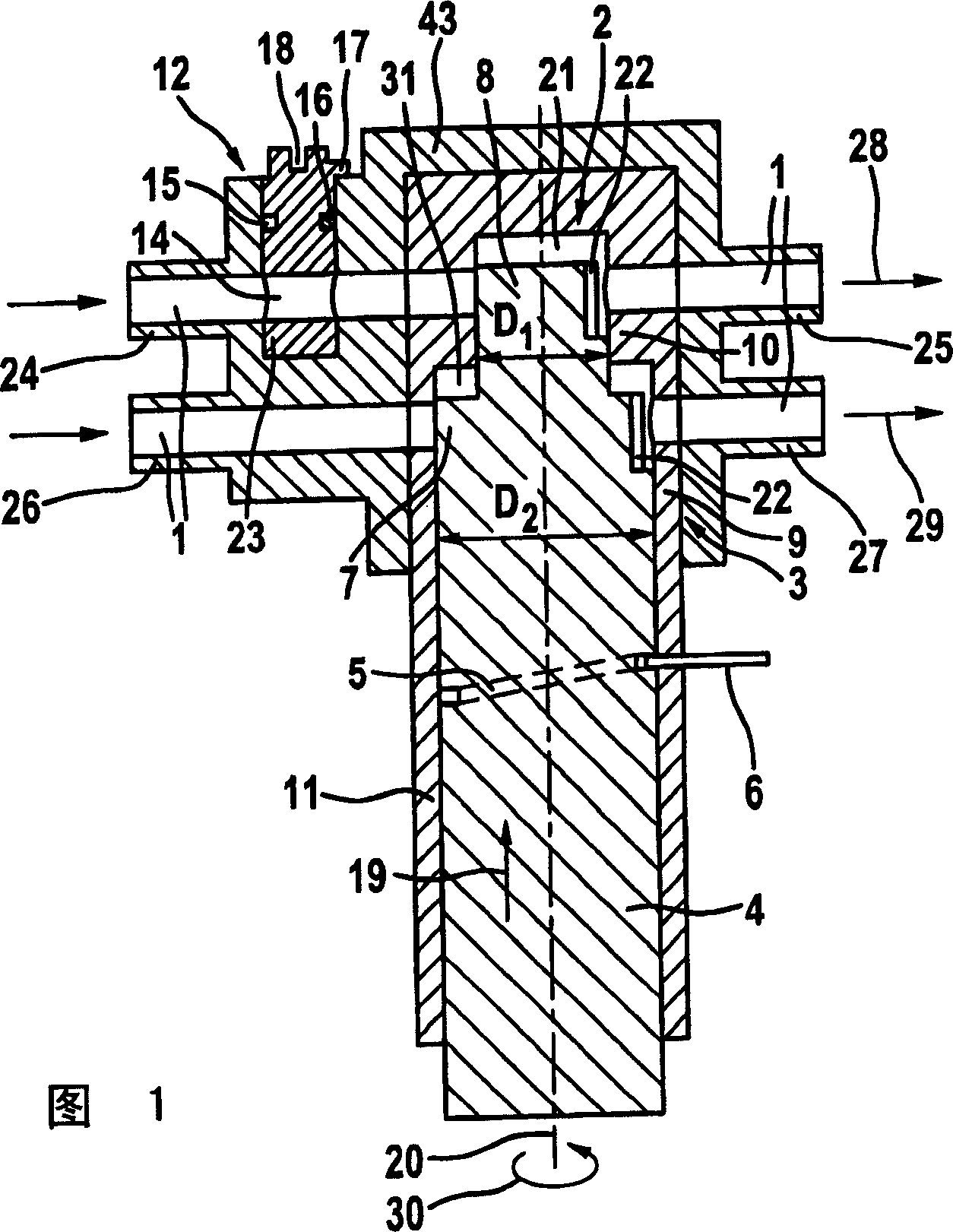

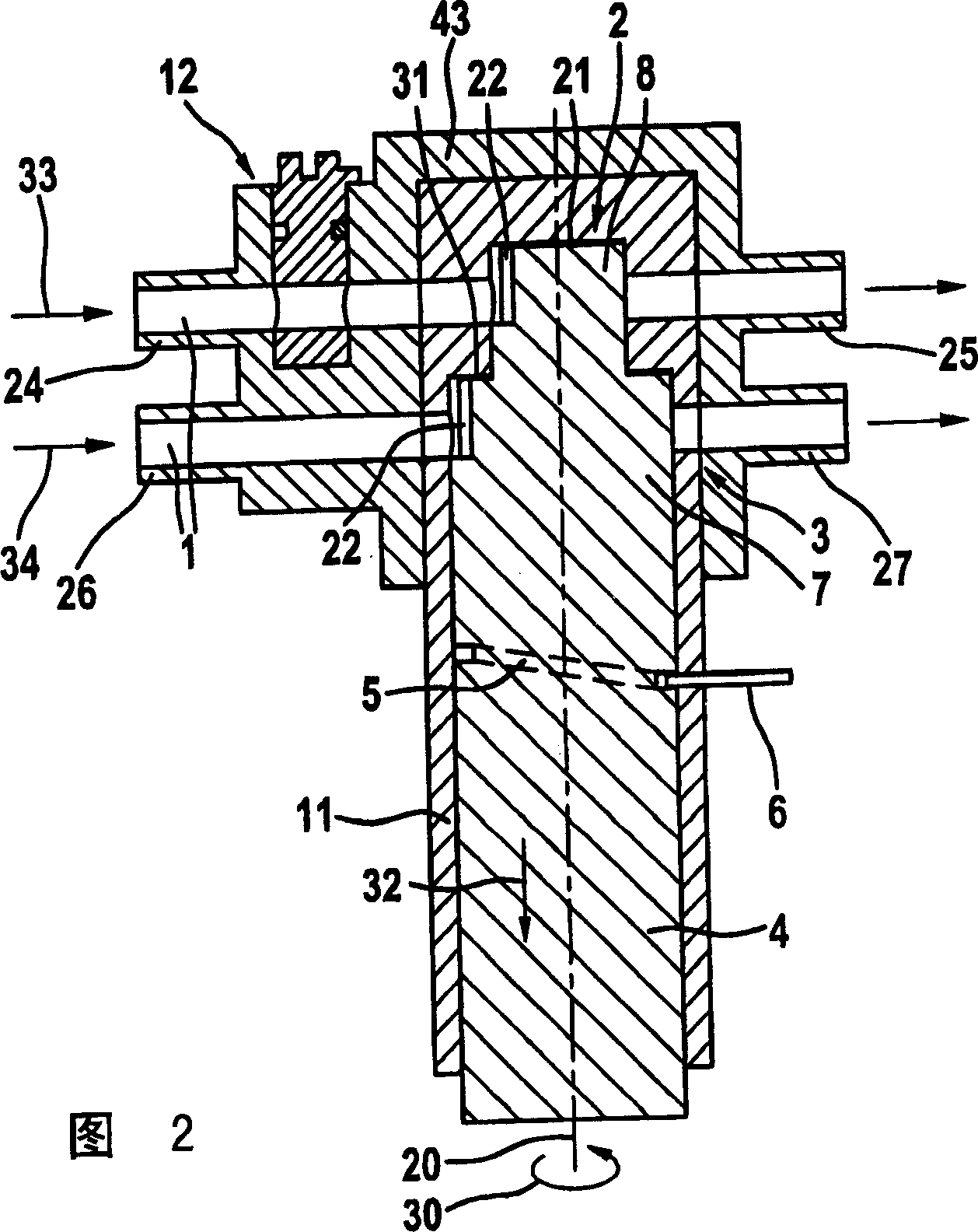

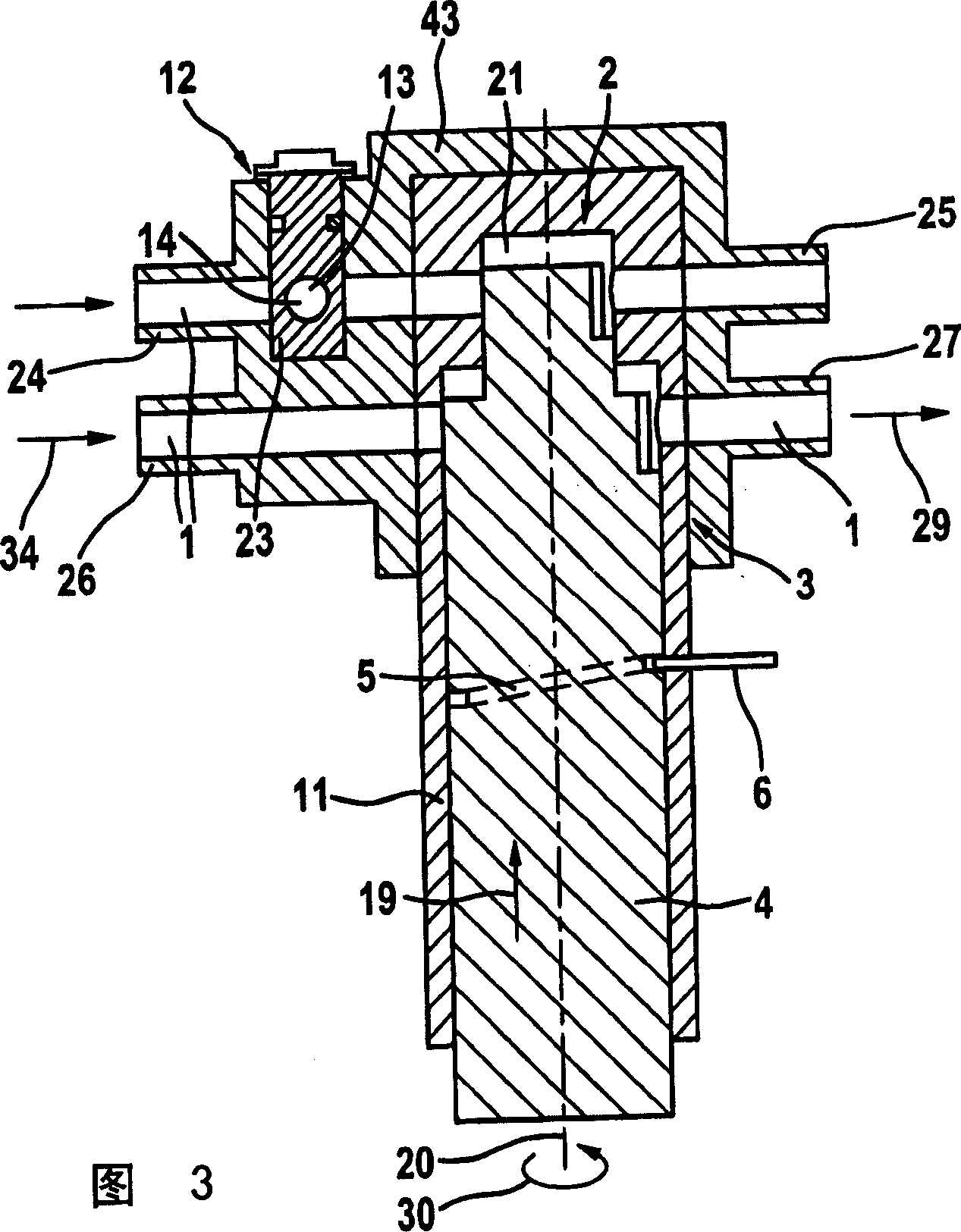

[0026] FIG. 1 shows a sectional view of a pump system for delivering lubricating oil 1 to a cutting chain (not shown) of a chain saw. The pump system includes a user-adjustable oil pump 2 and a base oil pump 3 . The two oil pumps 2, 3 have input pipes 24, 26 and output pipes 25, 27 respectively. The lubricating oil 1 is sucked in through the inlet pipes 24 , 26 and pushed out through the outlet pipes 25 , 27 . The adjustable oil pump 2 and the base oil pump 3 communicate with the same oil tank (not shown) through respective inlet pipes 24 , 26 . The two output pipes 25, 27 lead to the cutting chain of the chain saw, so the two oil pumps 2, 3 are connected in parallel. In order to realize multiple conversion stages, other adjustable oil pumps 2 can be connected in parallel.

[0027] The pump system may be a system with a gear pump, a diaphragm pump or the like, but in the illustrated embodiment is implemented as a piston pump system. For this purpose, a piston part 4 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com