Compact planar membrane filtering piece, membrane filtering unit and apparatus

A flat-plate membrane and filter element technology, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as incoordination and unbalanced sealing of components, and achieve low manufacturing cost, high packing density, The effect of low on-site assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further illustrate the present invention below in conjunction with accompanying drawing.

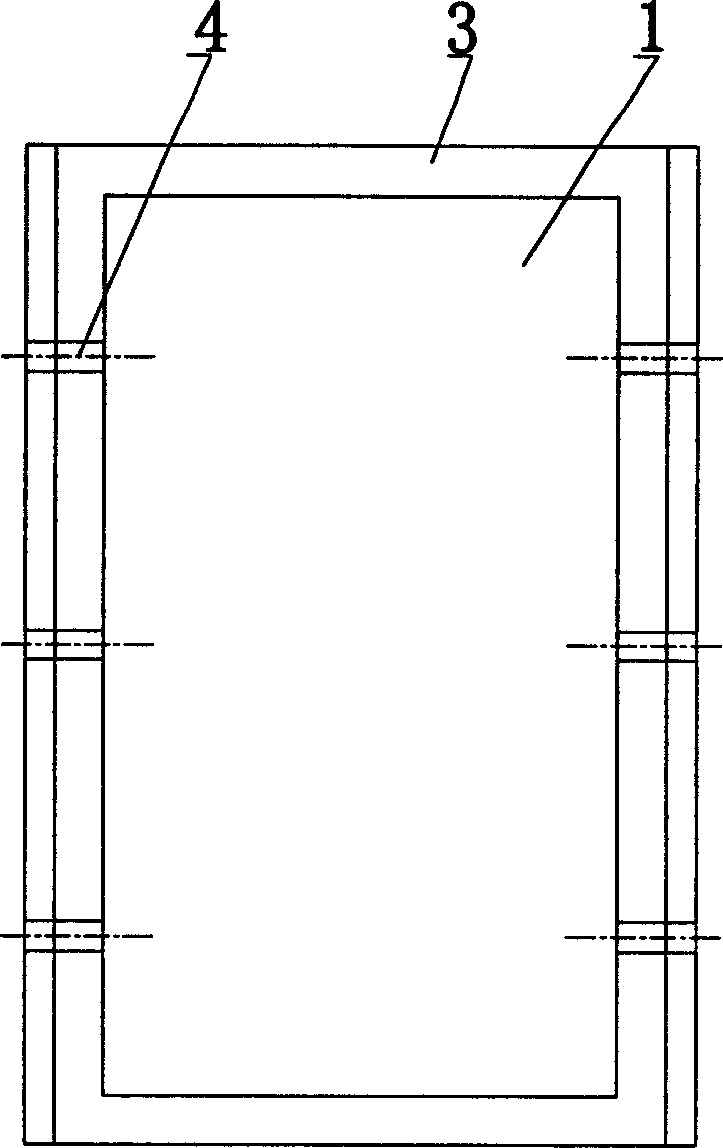

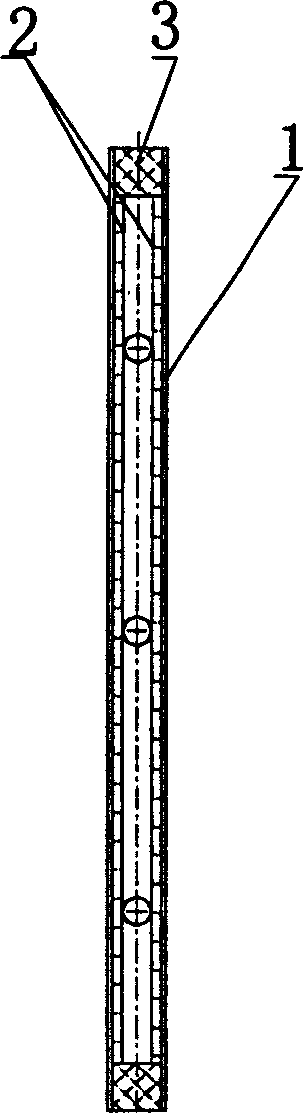

[0026] see figure 1 , figure 2 The membrane filter sheet of the present invention comprises a filter membrane 1, a membrane diversion support layer 2 and a framework 3 that is connected with the diversion support layer to fix the filter membrane and the diversion support layer, and the filter membrane is positioned at both sides of the diversion support layer. One or more diversion openings 4 are symmetrically opened on the frame in the length direction of the filter sheet, and the filter membrane is sealed and connected with the frame.

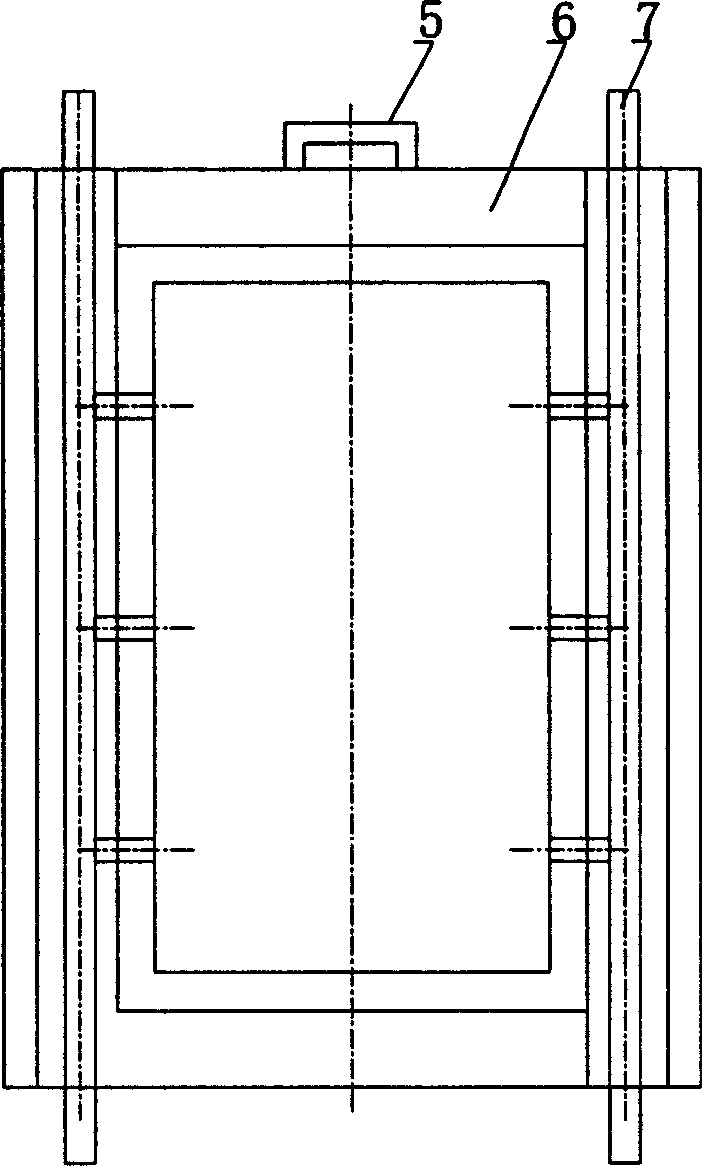

[0027] see image 3 , Figure 4 , the flat membrane filter element of the present invention includes a membrane filter sheet and a combined outer frame 6. The inner side of the outer frame has a diversion groove 8 for the filtered fluid, the longitudinal outer side has a groove 9 for fixing the membrane filter element, and the lateral outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com