Shower head, device and method for manufacturing thin films

A technology for manufacturing devices and nozzles, used in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve problems such as turbulence, convection, and thermal convection without special consideration, ineffective removal, and particle generation. Effects of suppressing decomposition and precipitation, improving productivity and mass productivity, and extending maintenance intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

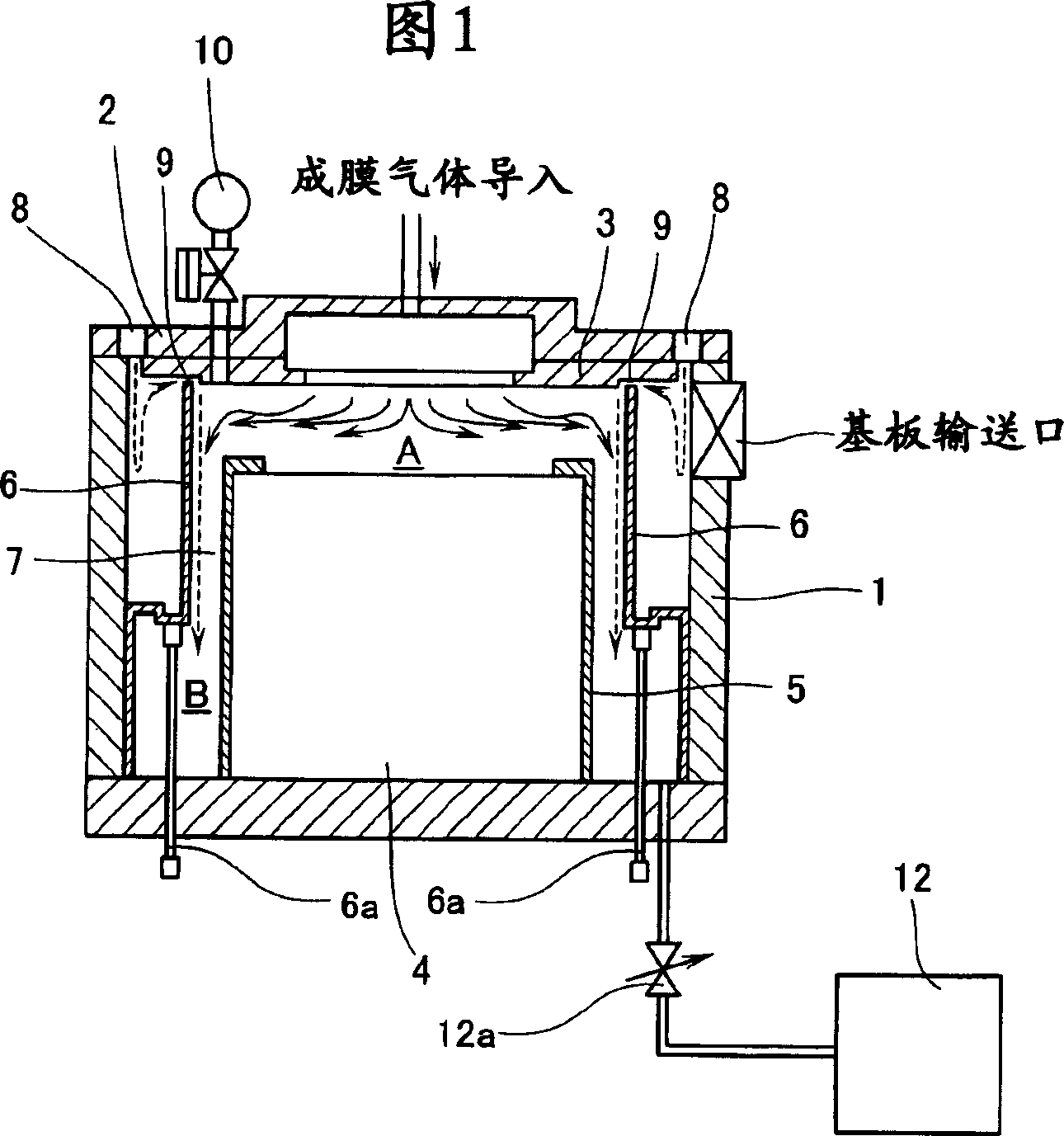

[0070] In the following, standard film-forming conditions for producing a PZT film by the MOCVD method are mentioned, and film formation was carried out under these conditions using the apparatus of the present invention.

[0071] (raw material) (concentration) (set flow rate)

[0072] Pb(dpm) 2 / THF 0.3mol / L 1.16mL / min

[0073] Zr(dmhd) 4 / THF 0.3mol / L 0.57mL / min

[0074] Ti(iPrO) 2 (dpm) 2 / THF 0.3mol / L 0.65mL / min

[0075] N 2 (carrier gas) 500sccm

[0076] (reactive gas)

[0077] o 2 2500 sccm

[0078] (inert gas around gas head)

[0079] N 2 1500 sccm

[0080] Film forming pressure: through the pressure regulating valve, it has been adjusted to be constant at 5 Torr.

[0081] Substrate temperature: 580°C

[0082] Spray plate-substrate distance: 30mm

[0083] Using the thin film manufacturing apparatus shown in FIG. 1, on an 8-inch electrode substrate mounted on a substrate stage 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com