Electronic components and their manufacture

A technology for electronic parts and a manufacturing method, applied in the field of electronic parts and their manufacturing, can solve the problems of high ACF price, difficult alignment of conductive terminal plates, and laborious filling resin injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the accompanying drawings in the following description are schematic diagrams of the structures of various embodiments of the present invention, and the shapes and size ratios in the drawings do not represent the actual shapes and sizes of the present invention.

[0054] (first embodiment)

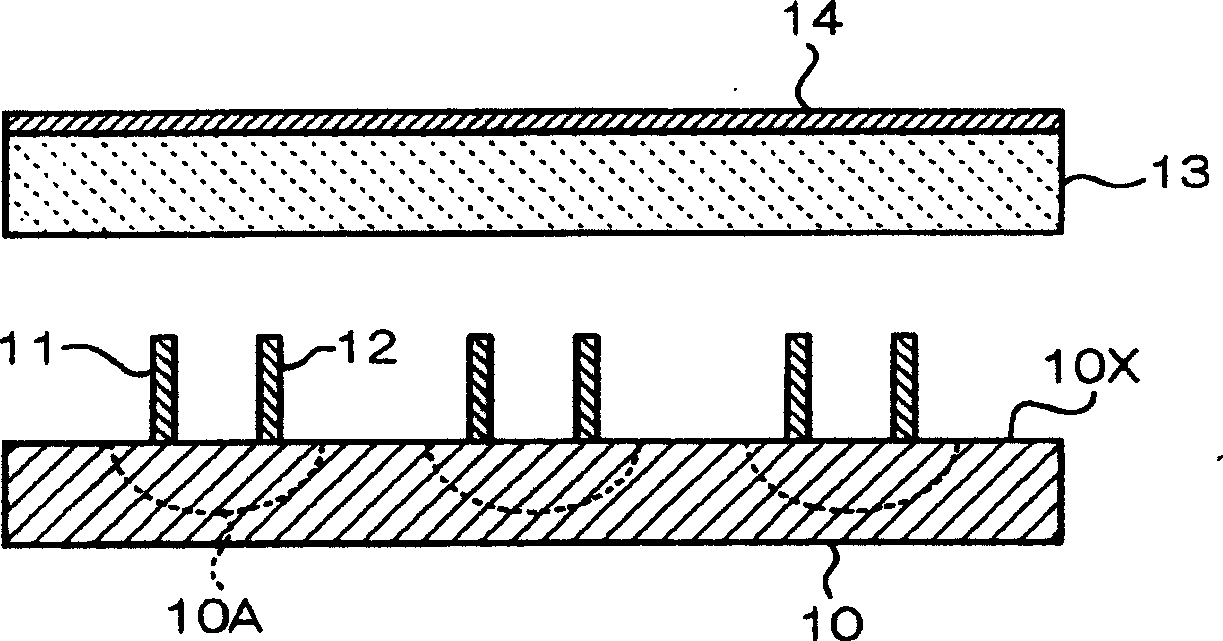

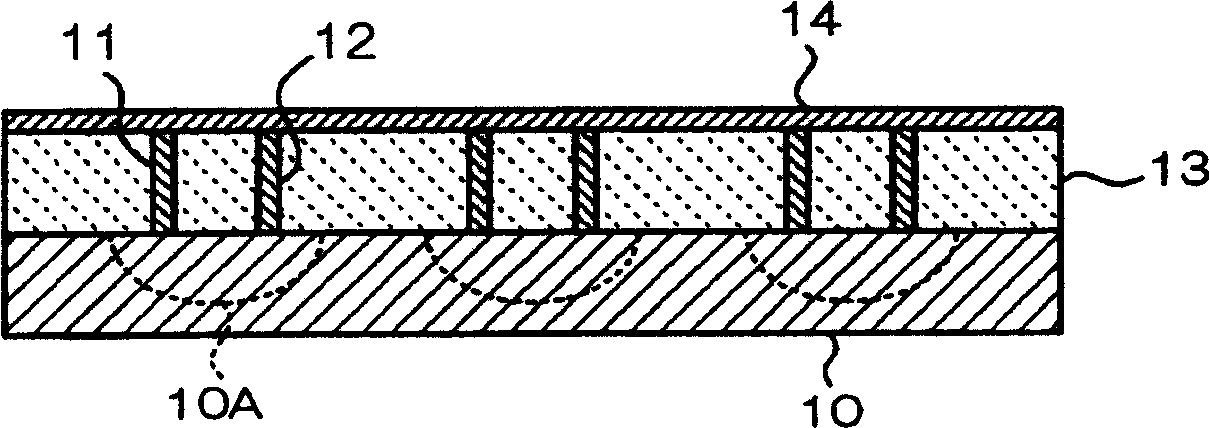

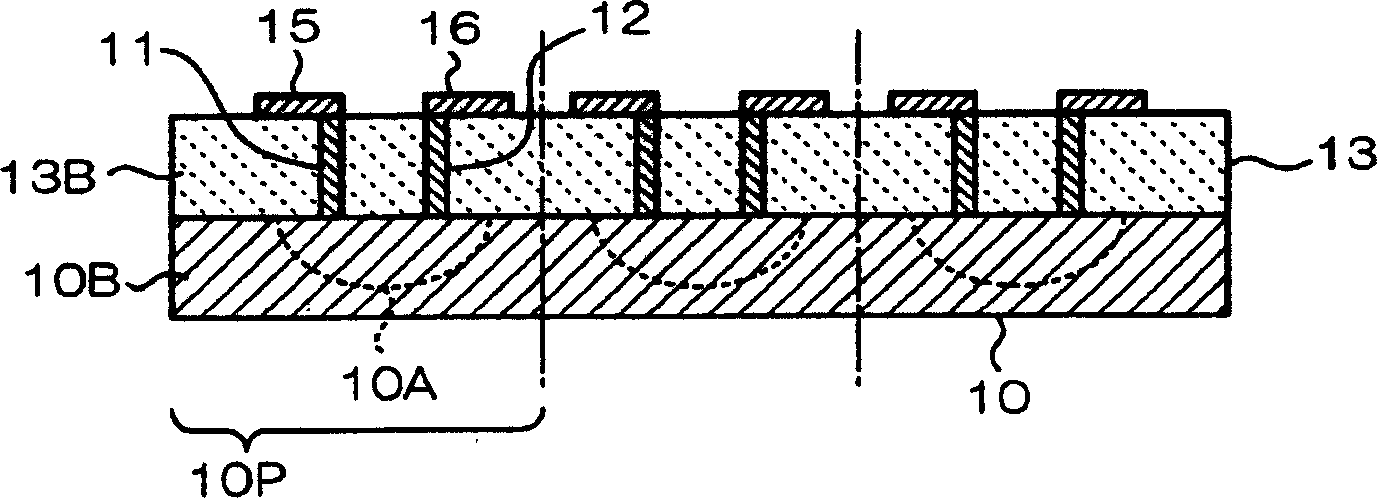

[0055] First, refer to Figure 1A to Figure 1C , the first embodiment of the present invention will be described. In this embodiment, if Figure 1A As shown, a semiconductor substrate 10 in which a plurality of integrated circuits 10A are integrated is prepared. The semiconductor substrate 10 is made of single crystal silicon or a compound semiconductor single crystal, and may be a semiconductor substrate having a predetermined electronic circuit structure as the integrated circuit 10A. Alternatively, the semiconductor substrate 10 may also be a ceramic substrate. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com