Liquid cooling radiator

A cooling device and liquid cooling technology, which is applied in the direction of instruments, electrical digital data processing, electrical components, etc., can solve the problems of difficult system configuration and increased radiator volume, and achieve the effect of compact structure and easy configuration of the cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

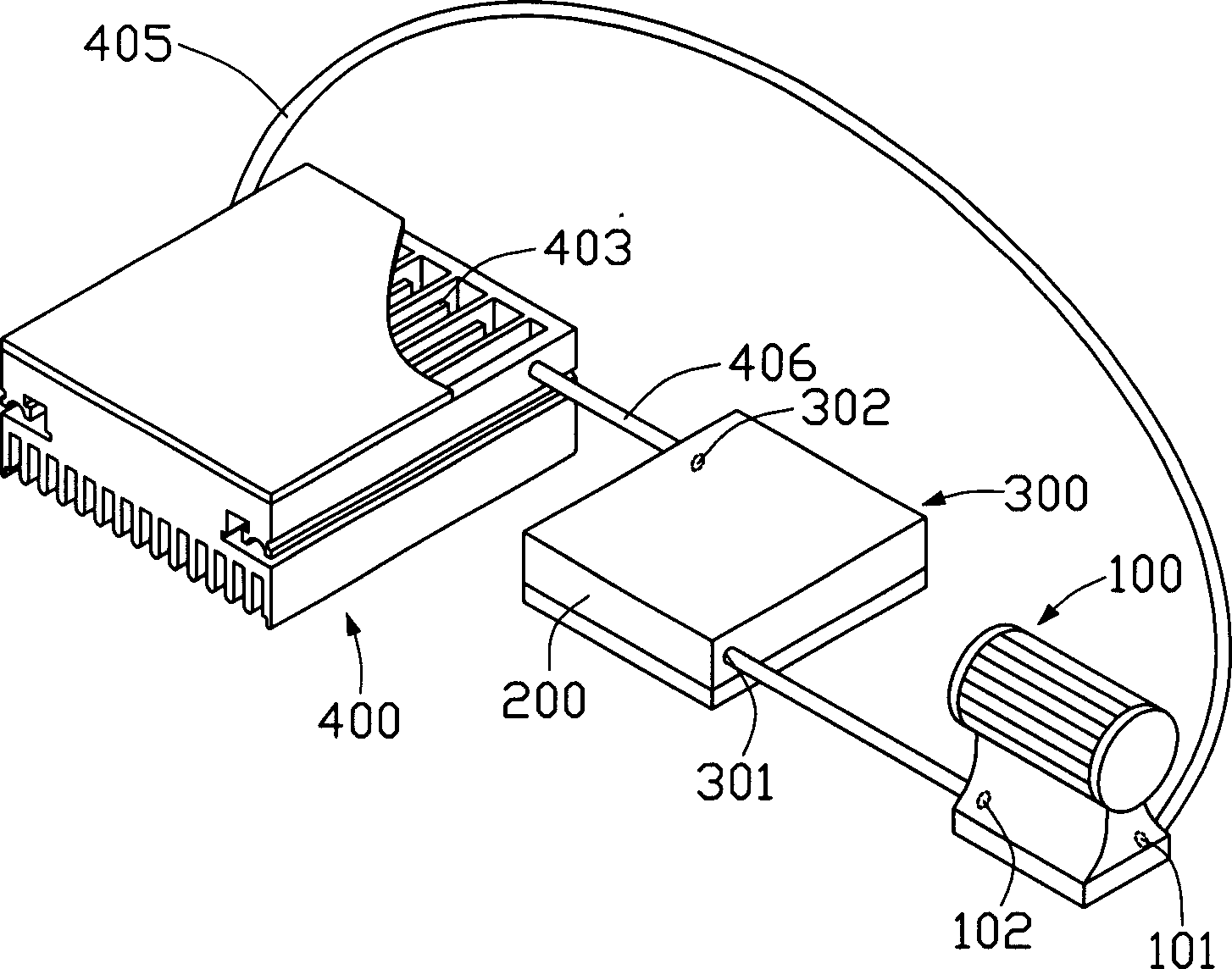

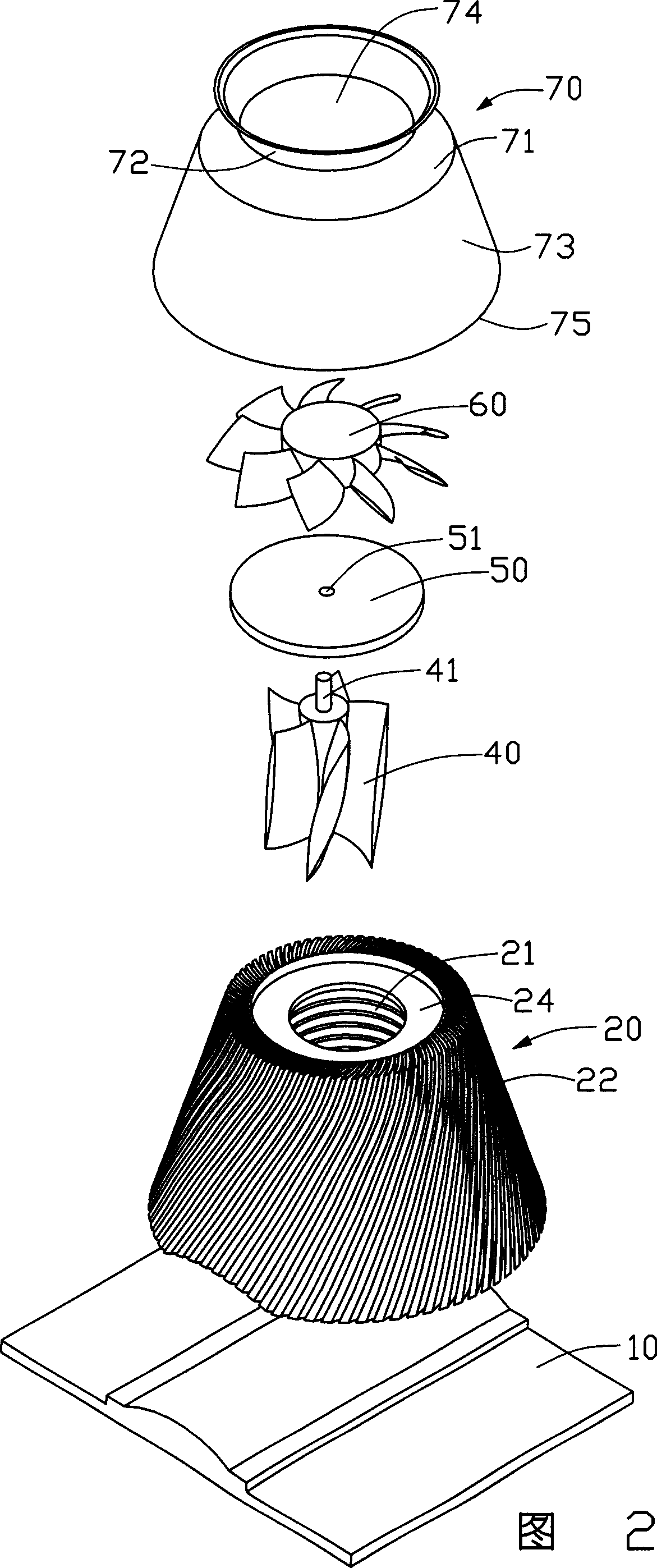

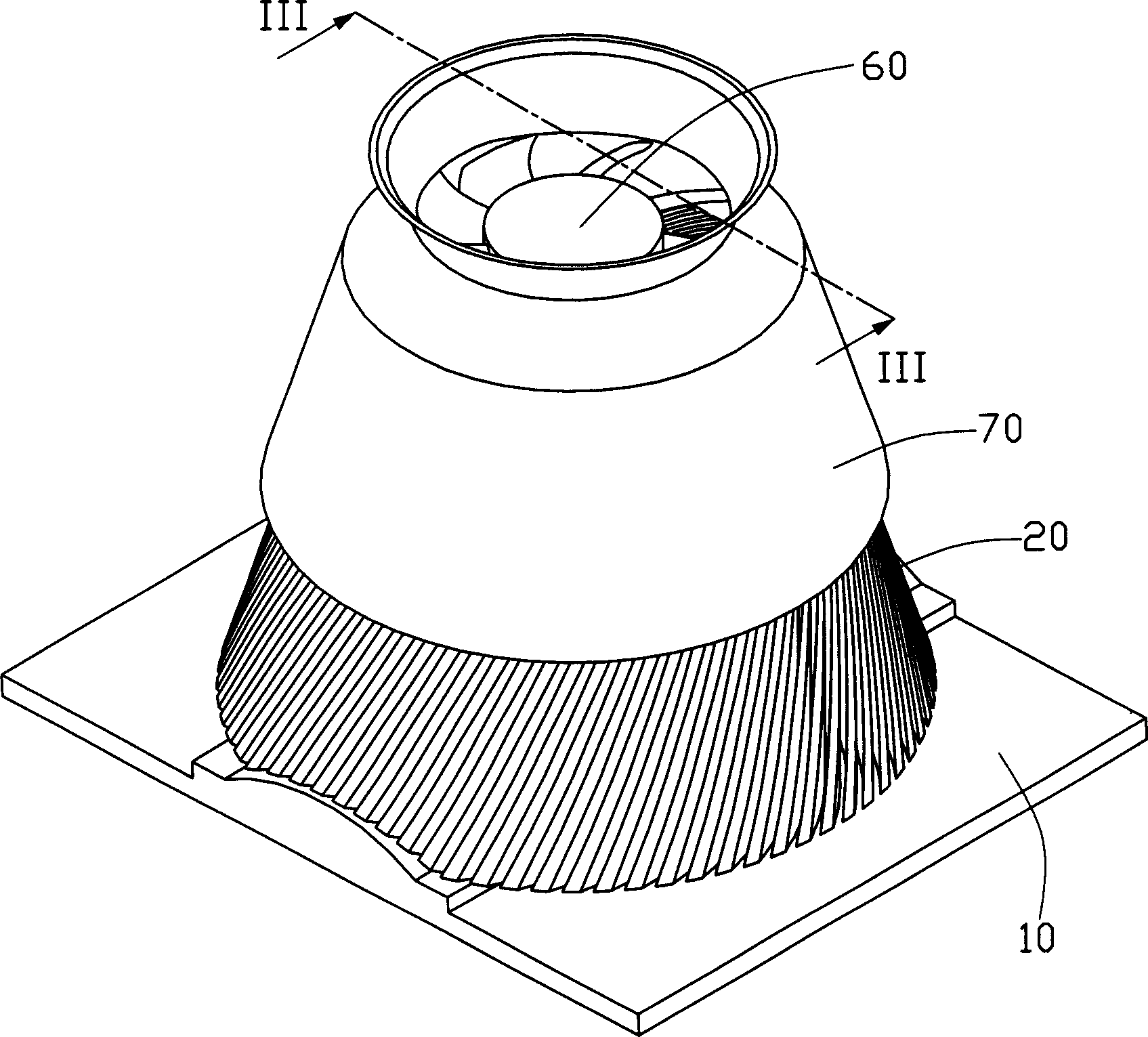

[0016] Please also refer to Figure 2, image 3 and Figure 4 , the liquid-cooled heat dissipation device of the present invention is used to assist electronic components (not shown in the figure) to dissipate heat. It includes a base body 20. A cavity 21 is formed inside the base body 20. The cavity 21 is filled with a working liquid, usually water, and the base body 20, the outer wall surface (not marked) is provided with a plurality of cooling fins 22; a base 10 is used to support the base 20; a liquid cooling fan 40 is extended in the base cavity 21; a connecting plate 50, wherein A through hole 51 is opened therebetween; an air cooling fan 60 is located above the connecting plate 50 and is connected with the liquid cooling fan 40 through the through hole 51 passing through the connecting plate 50 through a shaft 41 ; and a housing 70 .

[0017] The base 10 is flat, with an arc-shaped protrusion (not shown) in the middle, so that the central part where the heat is concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com