Semidry desulfurization product oxidized in fluidized bed through utilizing solid thermal carriers as initial heat source

A semi-dry desulfurization and solid heat carrier technology, which is applied in the field of oxidizing semi-dry desulfurization products to realize waste recycling, can solve the problem of large purification equipment, large total amount of combustion flue gas and oxidized exhaust gas, and short powder residence time. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

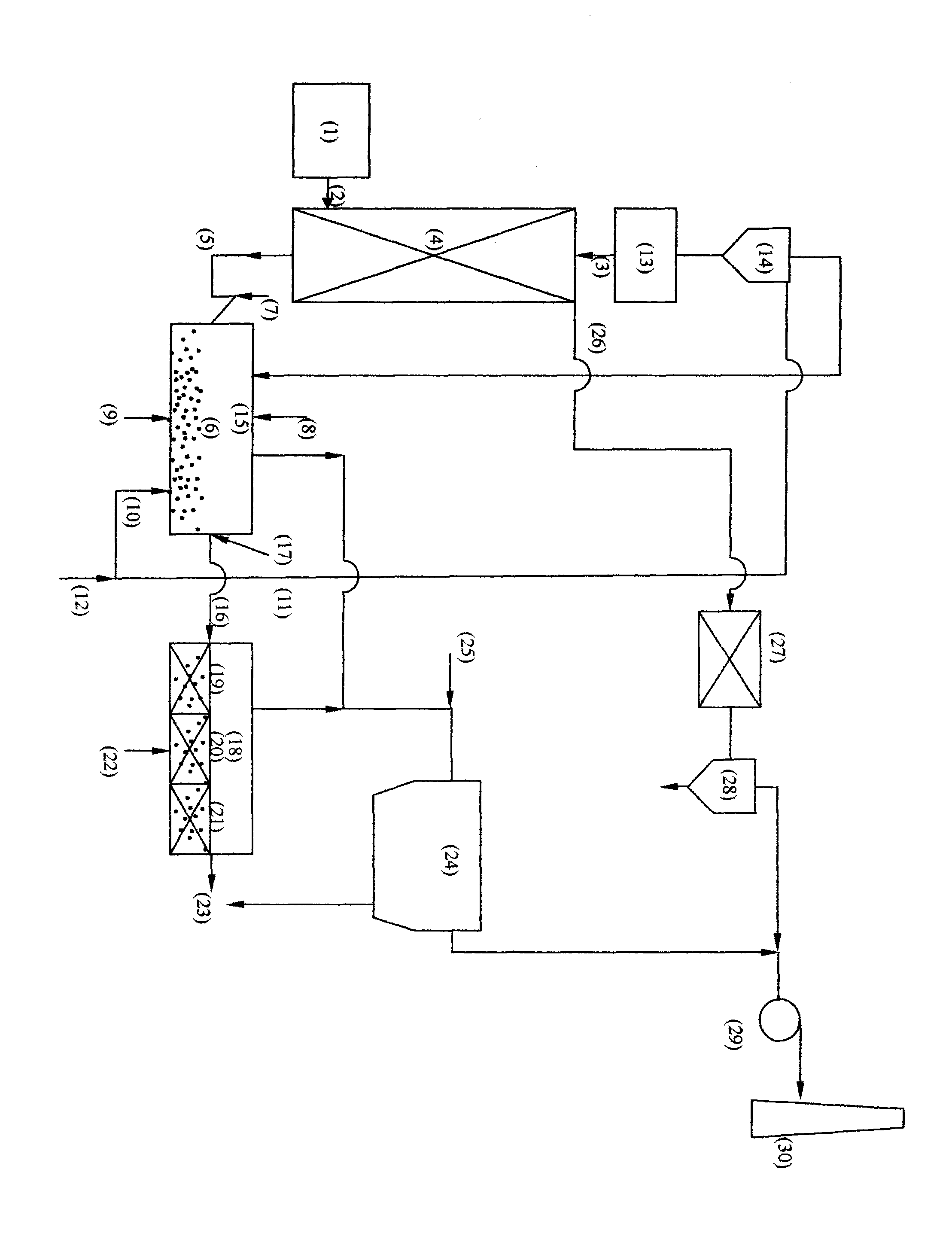

[0008] The present invention is realized as follows: the primary heat source for oxidizing the semi-dry desulfurization product containing calcium sulfite is high-temperature solid heat carrier particles, and the waste heat recovery and cooling after oxidation and oxidation are completed in a fluidized bed. Such as Figure 1 As shown, the pre-combustion furnace (1) burns coal or gas to produce flue gas (2) at 1000-1400°C, and the flue gas exchanges heat with the solid heat carrier (3) in the gas-solid heat exchanger (4), and the solid heat The carrier particles are heated from 300-400°C to 800-1000°C, and the flue gas is lowered to 350-450°C. The high-temperature solid heat carrier particles enter the oxidation fluidized bed (6) through the J-shaped valve (5) located at the bottom of the gas-solid heat exchanger, and the semi-dry desulfurization products to be oxidized are sent into the oxidation fluidized bed in two times, first 50 ~70% of the raw material (7) is sent to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com