Holographic aiming optical element and its producing method and use

An optical element and holographic technology, applied in optical elements, optics, telescopes, etc., can solve the problems of difficult to see the laser spot, unfavorable effective aiming, and the laser being discovered by the enemy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

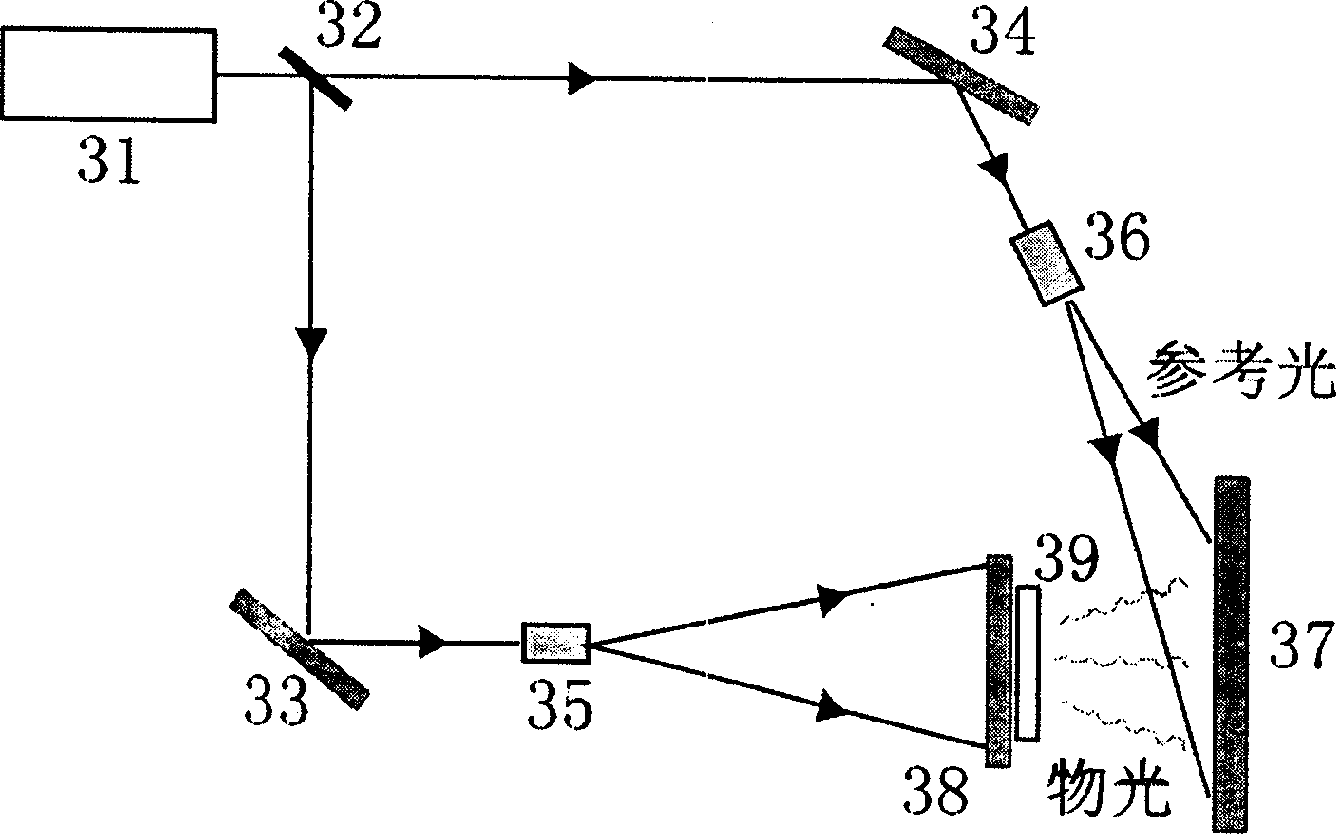

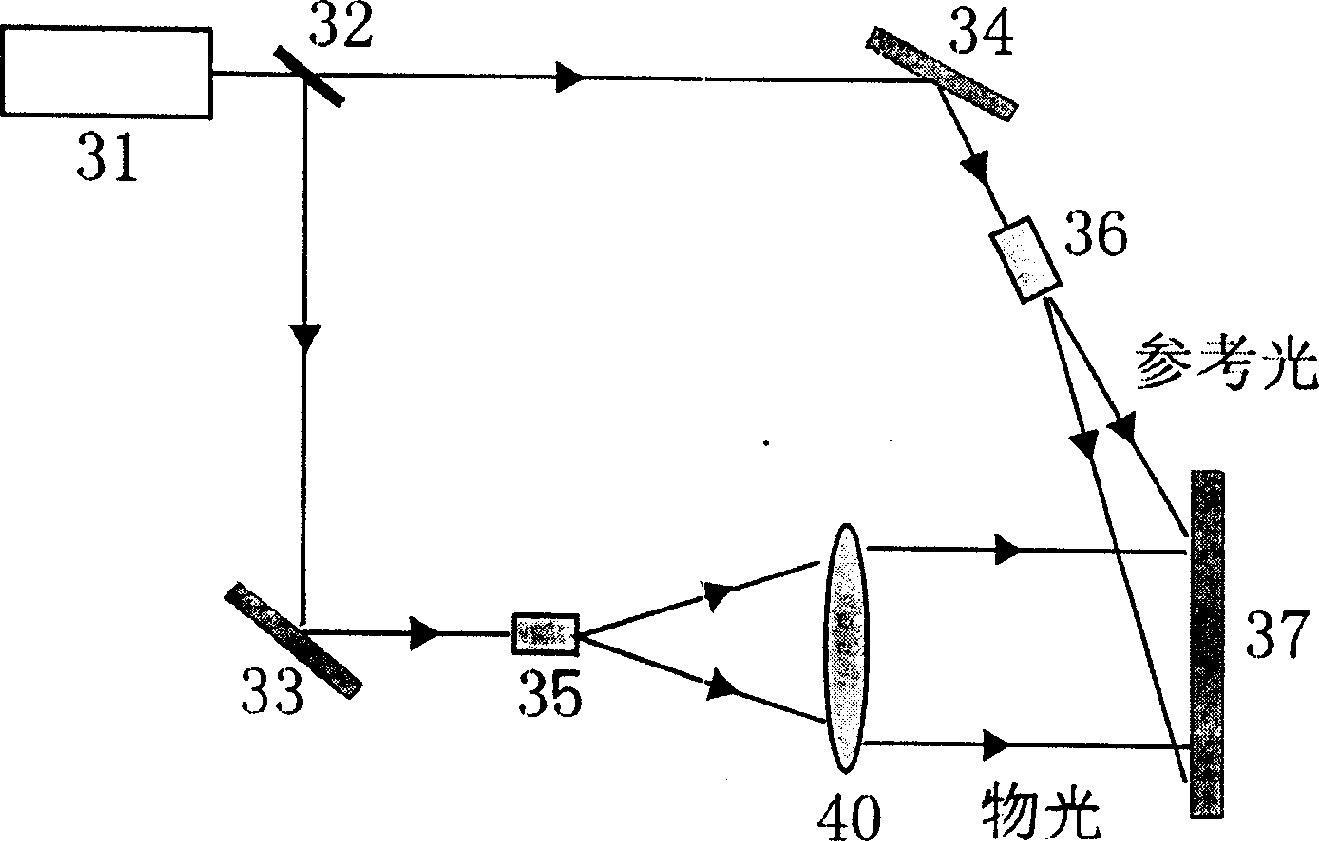

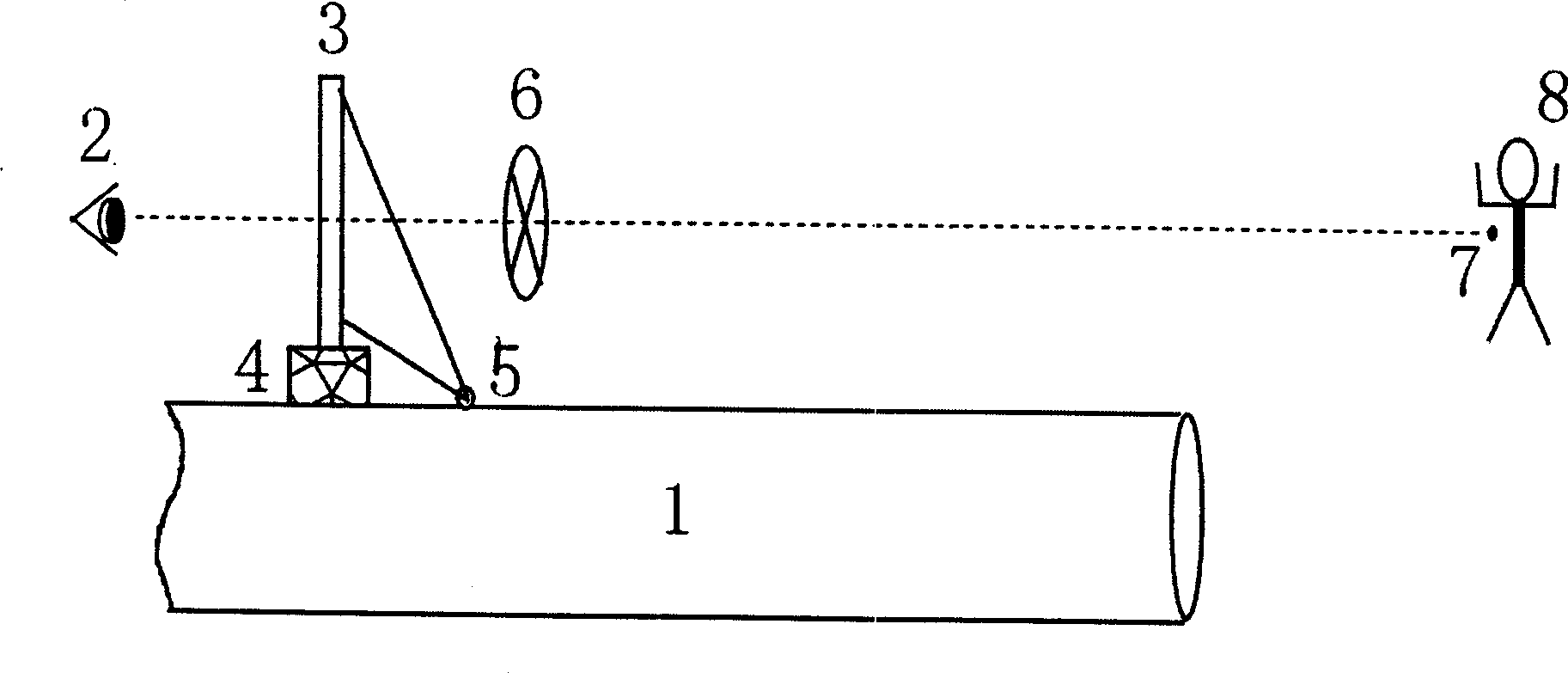

[0020] Such as figure 1 , As shown in 2, the present invention adopts the method of secondary exposure to a holographic recording dry plate to make a holographic aiming optical element. The first exposure records the information of a crosshair pattern, and the second exposure records the information of a tiny bright spot at infinity. The optics for the second exposure differ only in the object light path. The first recording device such as figure 1 As shown, a laser 31, a beam splitter 32, reflectors 33 and 34, beam expanders 35 and 36, a dry plate for holographic recording 37, a frosted glass 38 and a transparent sheet 39 with a crosshair pattern are provided. The frosted glass 38 is closely attached to the transparent sheet 39 with the crosshair pattern, and the distance from the holographic recording dry plate 37 is preferably several centimeters. The reference light uses beam expansion light, and the distance between the beam expansion filter 36 and the holographic reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com