Method for monitoring the risk of damage in a cooking plate or glass plate

A glass surface and stove technology, applied in induction heating devices, household appliances, household stoves/stoves, etc., can solve the problems of safety margin and inaccuracy of temperature measurement, inability to reliably obtain stress conditions, etc., and achieve large thermal expansion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

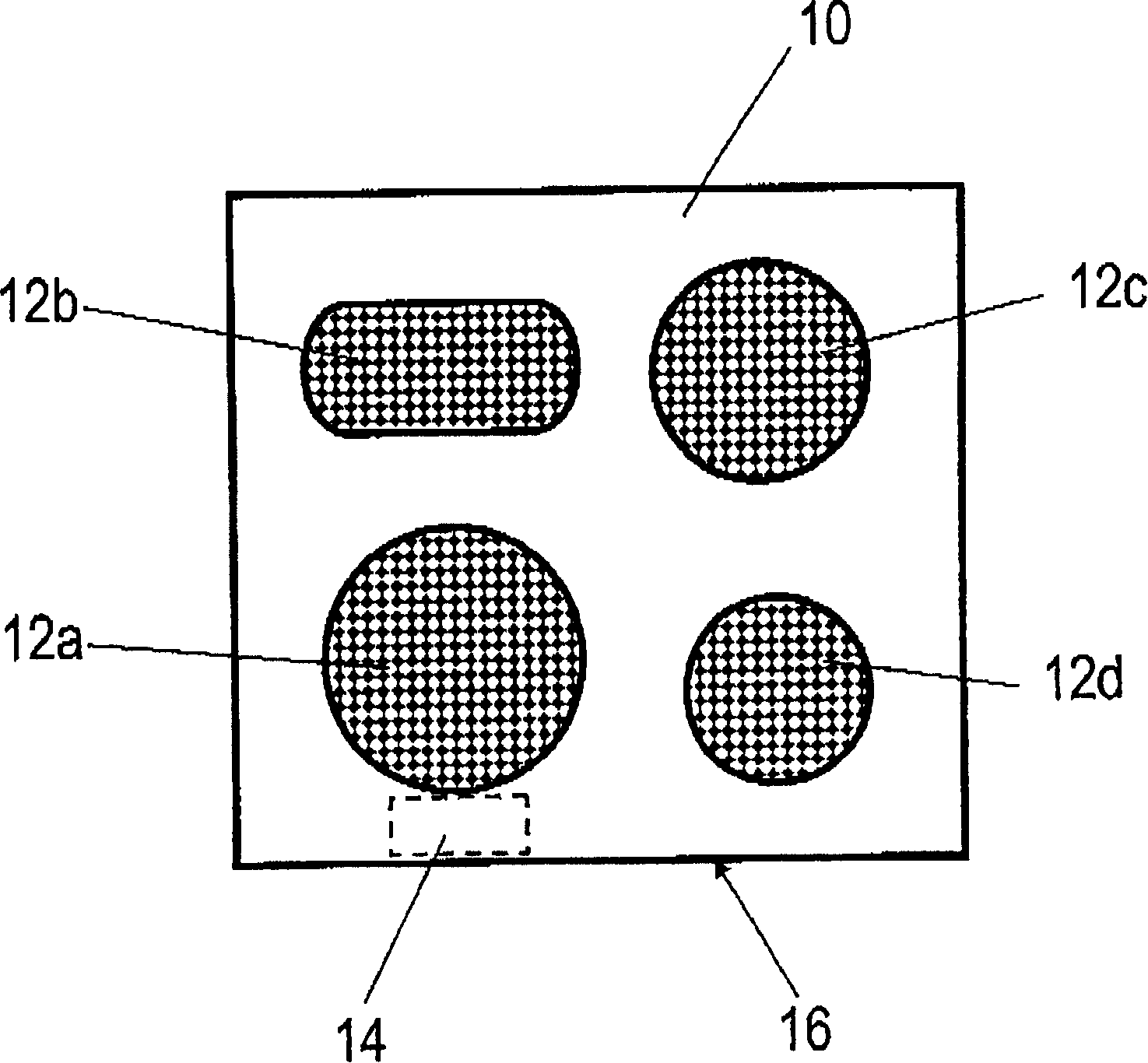

[0025] figure 1 Shown is a cooker surface 10 of a common household cooker device, with four cooking zones 12a, 12b, 12c and 12d arranged on the cooker surface 10 and heated by electric heating devices respectively. The focal areas 12a, 12c and 12d are circular and have different diameters. The cooking area 12b is elongated.

[0026] Possible damage to the cooker surface 10 due to the thermal effects of the four heating devices is monitored by determining the thermally induced mechanical stresses at critical points on the cooker surface or at positions of typical significance for this, so that the heating can be switched off if necessary heating of the device. The figure shows, for example, a region 14 lying on the side of the heating zone of the cooking zone 12a. This area 14 is determined by calculations carried out previously, for example by a stress analysis within the scope of simulation calculations. In the typical cooktop 10 shown, area 14 is also the area of great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com