Tectorial perform device and pultruder having the device

A technology of preforming and preforming group, which is applied in the field of FRP pultrusion molding machine, which can solve problems such as bad hand feeling, poor surface finish of products, and exposed glass fiber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

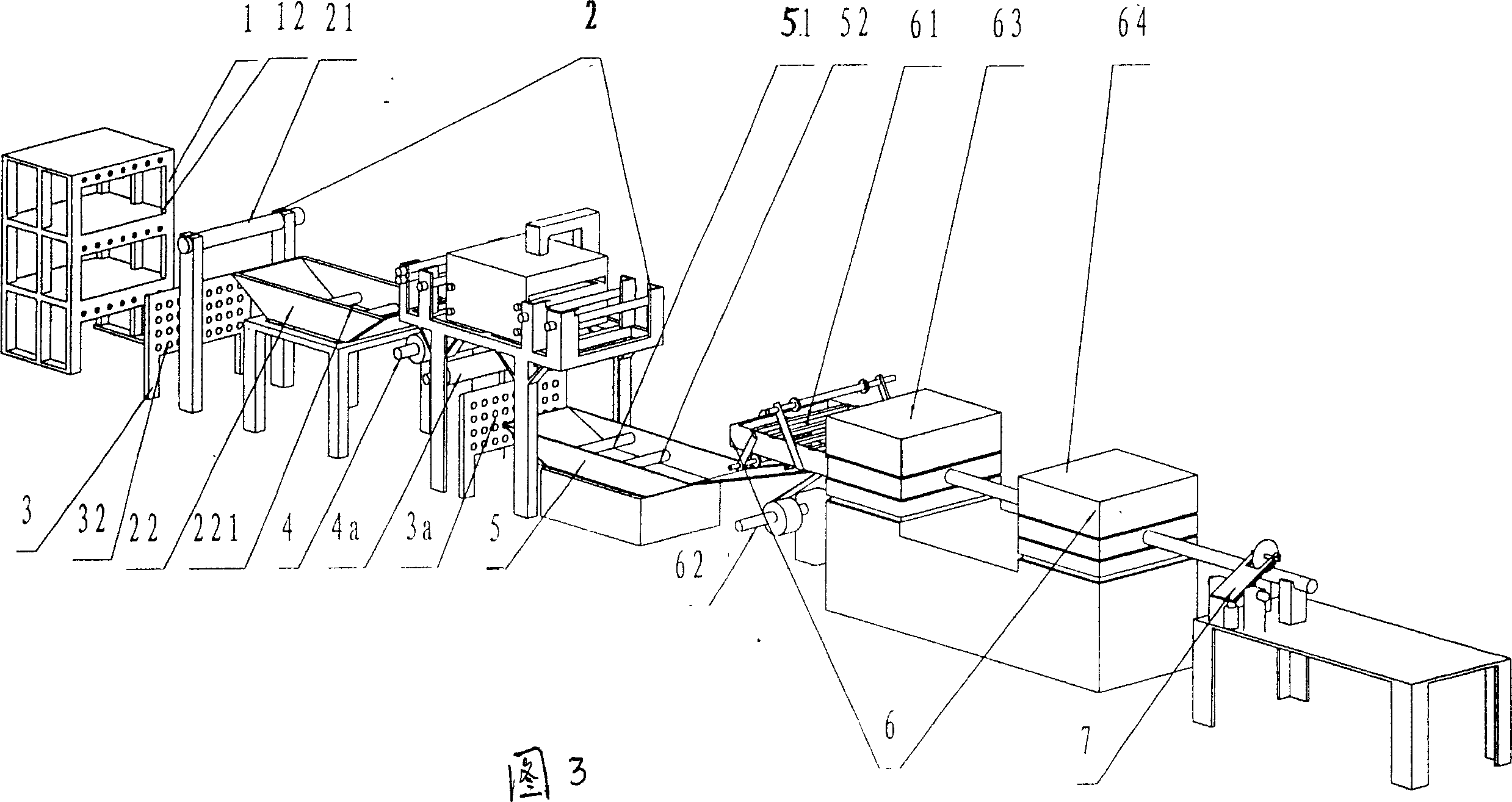

[0026] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

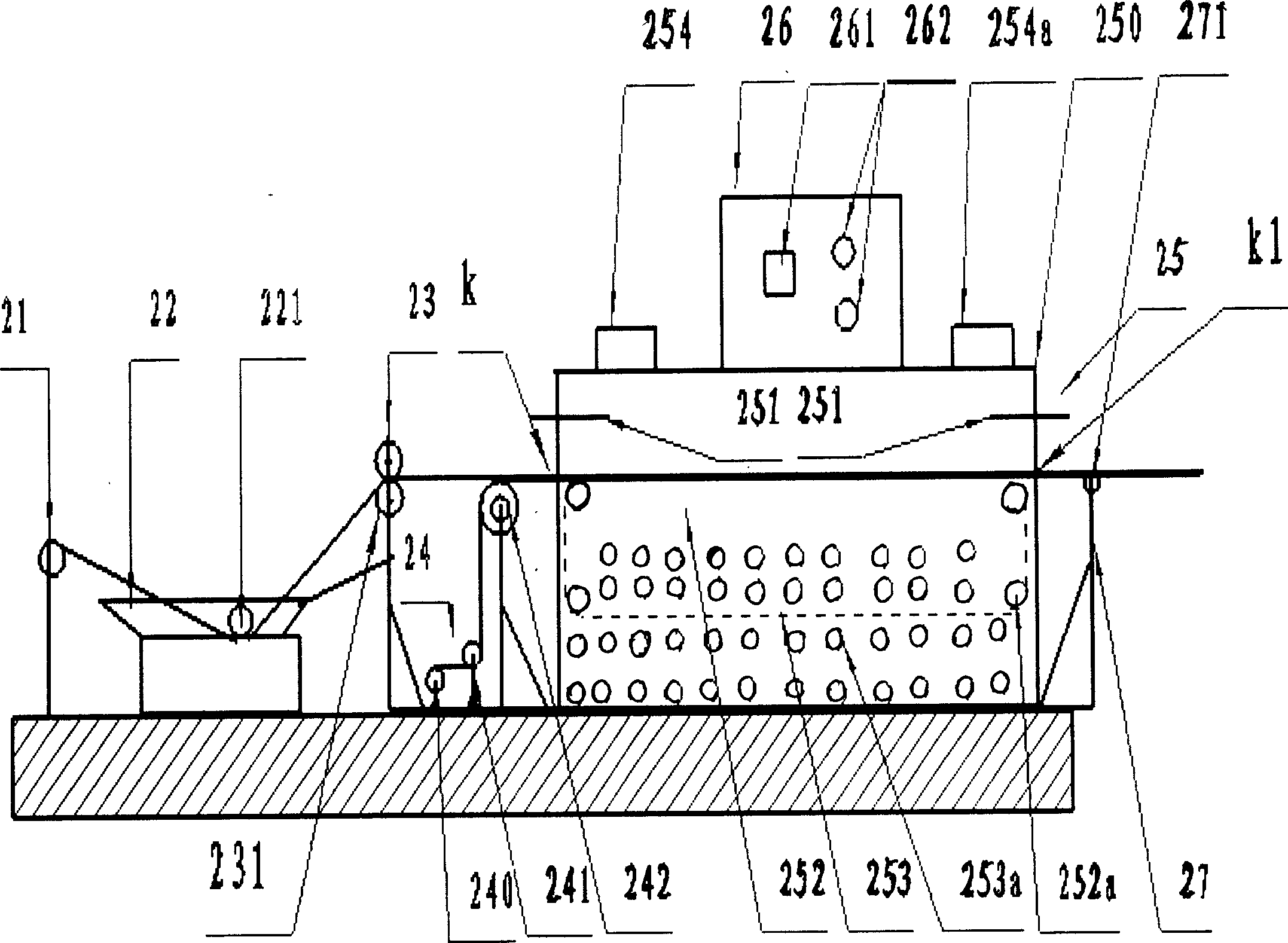

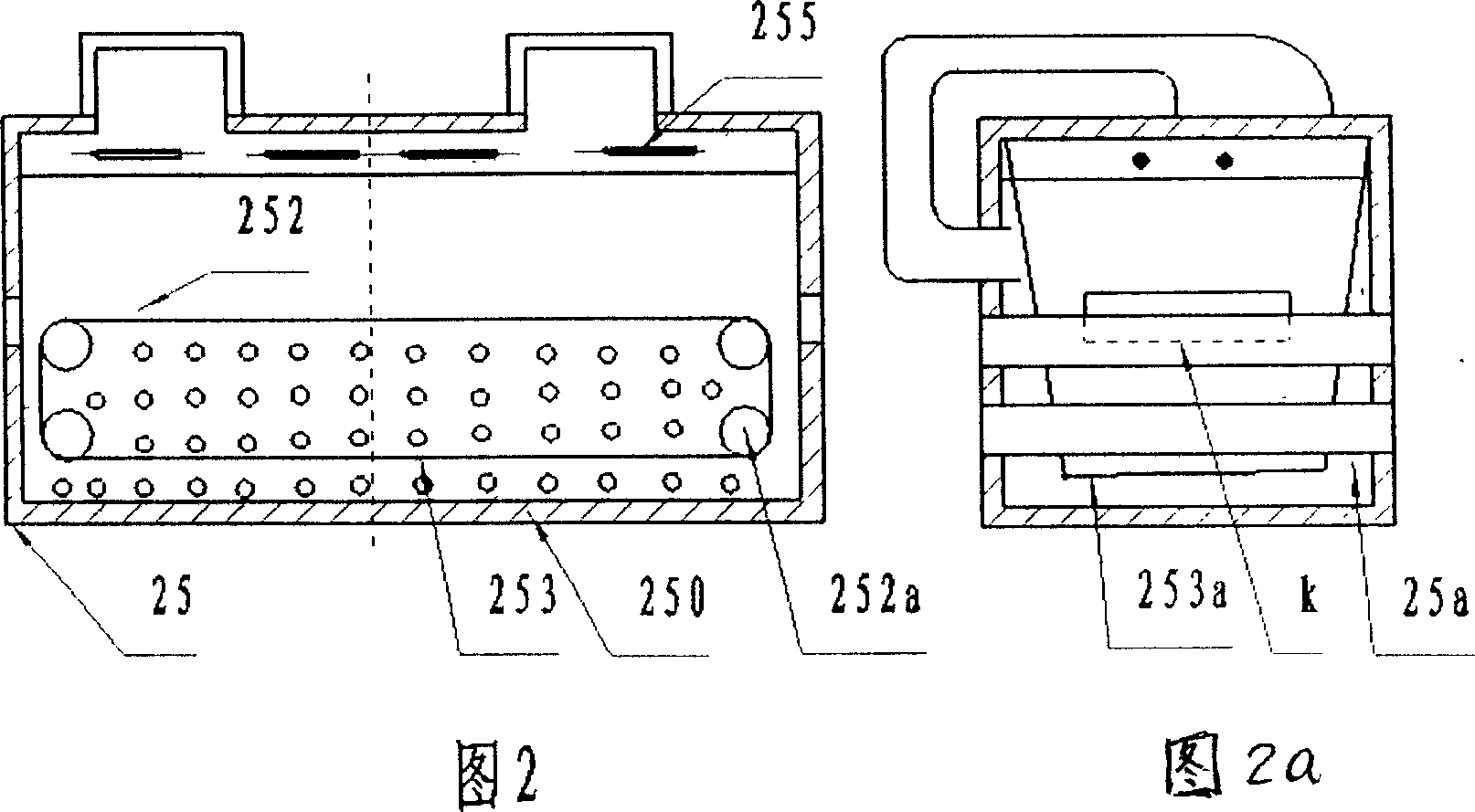

[0027] A film preforming device 2, comprising a feeding device 21, a dipping tank 22 and a preforming group 25 arranged in sequence, wherein the dipping tank 22 is set at the lower position of the feeding device 21 where the fiber mat is placed, the A pressure roller (221) is arranged in the dipping tank, so that the fiber felt can be fully and evenly dipped in the glue tank;

[0028] Adjacent to the lower position of the dipping tank 22, a rubber extrusion guide device 23 is arranged, and the device is equipped with two mutually rolling rubber extrusion rollers 231 through a bracket conforming to the height;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com