Automatic gun wiping machine

An automatic wiping and gun machine technology, which is applied to weapon accessories, offensive equipment, weapon cleaning devices, etc., can solve the problems of heavy weight, inconvenient carrying and use of AC motors, and achieve the effect of reducing volume and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

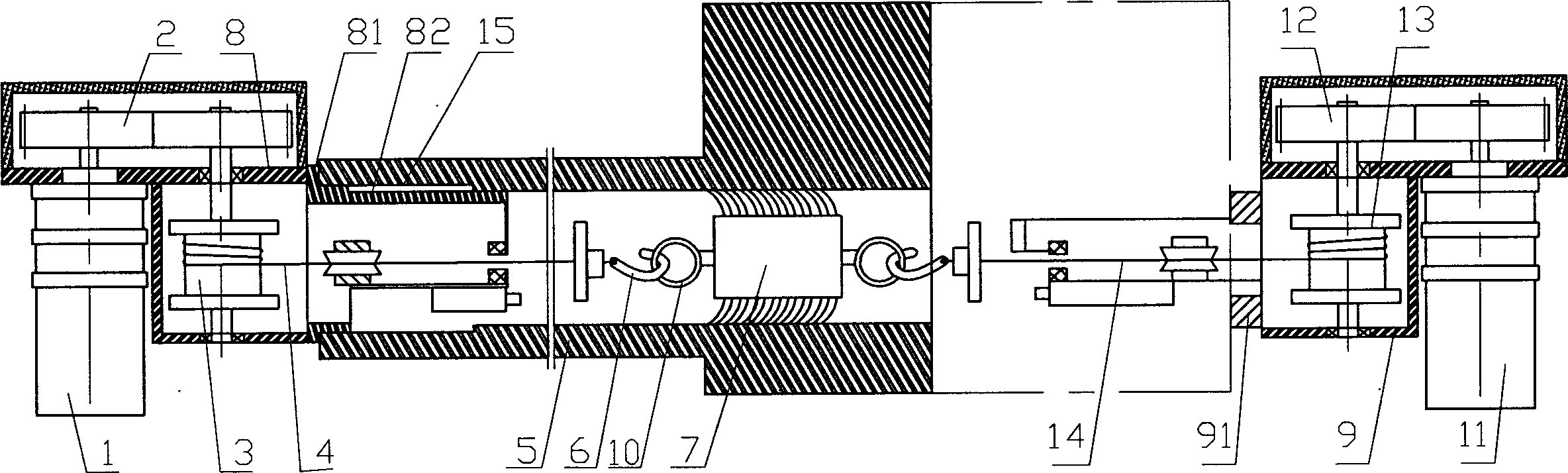

[0010] Such as figure 1 Shown, the present invention comprises driving motor 1 and driving motor 11 and controller, wiping body 7 and the driving mechanism that is connected with wiping body 7 and driving motor, is also provided with at front mount 8 and rear mount 9 front ends and The matching positioning device at gun barrel 5 two ends, its rear end is fixed driving motor, is all provided with driving mechanism between wiping body 7 and two driving motors, and the driving mechanism on the described front hitch 8 is with driving motor 1. The shaft is connected to the rope winch 3 by the gear set 2, and one end is fixed on the winch and the other end is provided with the stay rope 4 of the hook. 12 connected stay rope winch tube 13, one end is fixed on the winch tube and the other end is provided with the stay cord 14 of hook, the hook 6 on stay cord 4 and stay cord 14 cooperates with the hanging ring that wiping body 7 two ends are provided with, A lead ball cooperating with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com