Method of deflavoring soy-derived materials

A soybean flavor technology, applied in the preparation of alcoholic beverages, vitamin-containing food ingredients, food ion exchange membrane method, etc., to achieve high water solubility and water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

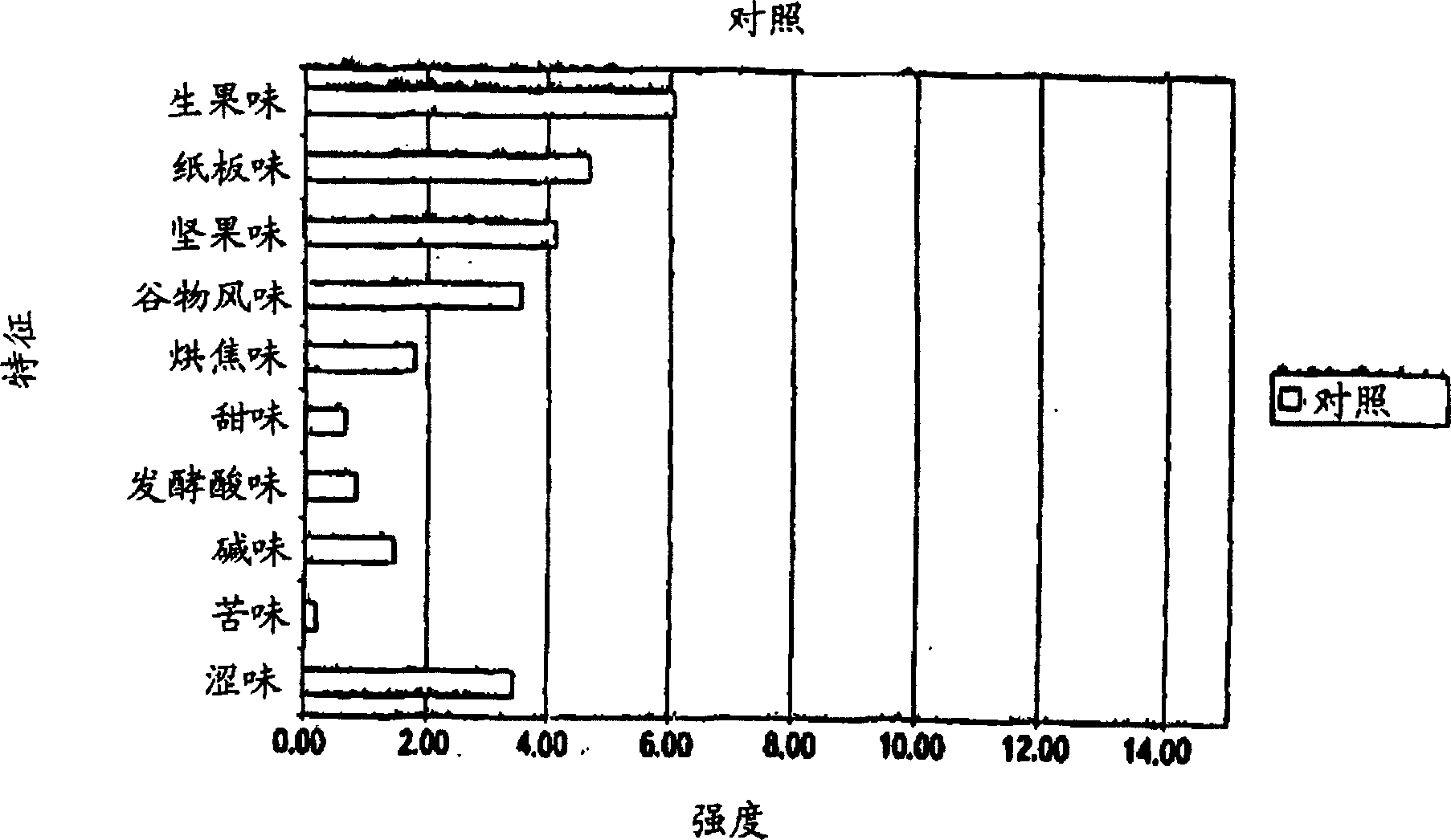

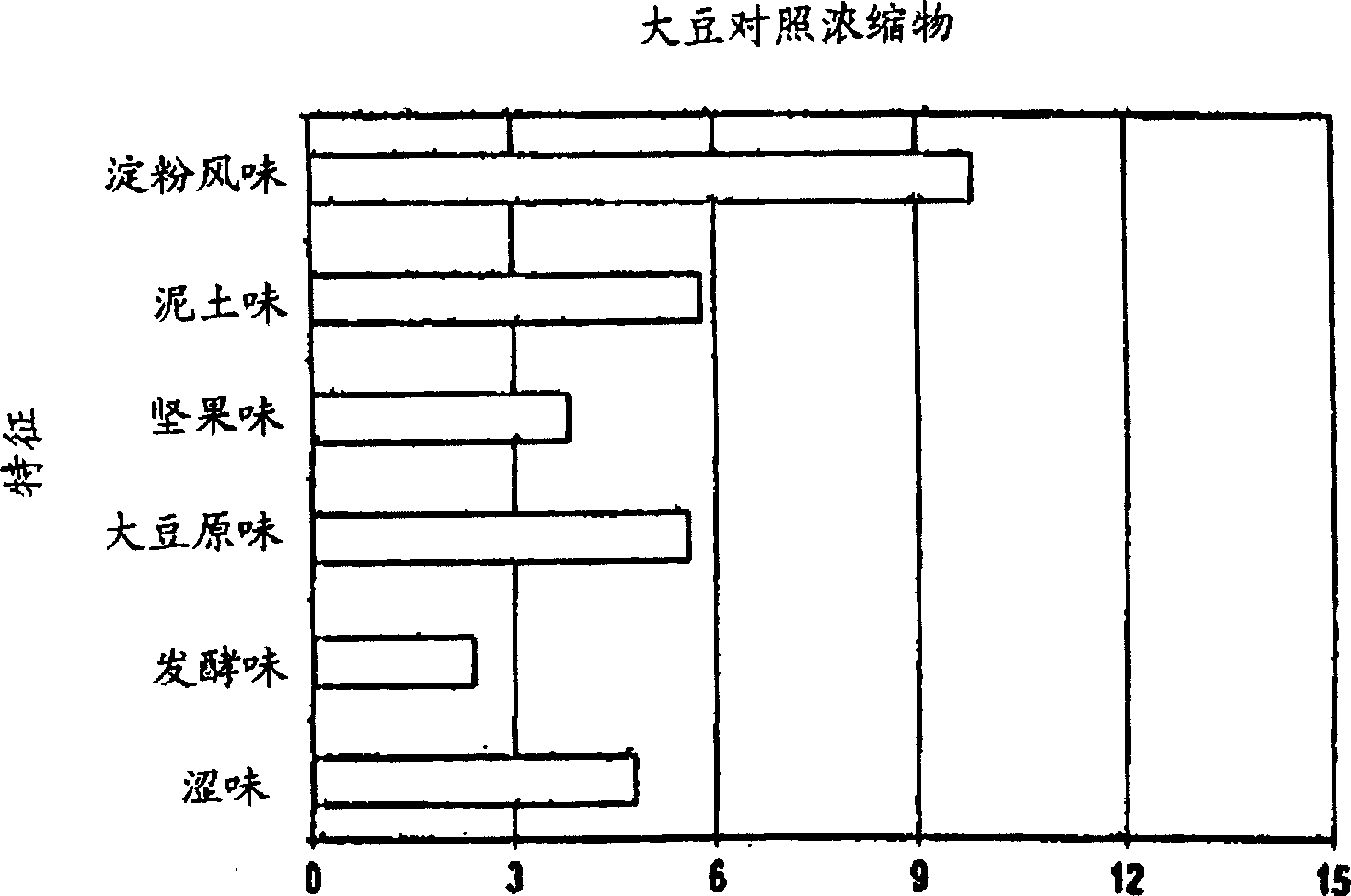

Embodiment 1

[0055] Example 1. Soy protein isolate (Protein technology International (PTI); St. Louis, MO) was hydrated with tap water to make the concentration 10%. The aqueous composition is mixed with a magnetic stirrer until all the soy protein isolate is completely dispersed. The pH of the mixture was adjusted to 11.0 with sodium hydroxide. Then, the pH-adjusted composition was placed in a dialysis tube (Spectrum, Inc) with a molecular weight pore size of 3500, and tap water was allowed to continuously flow through the outside of the dialysis tube for about 4 hours; the pH value remained greater than 9 during the dialysis process. The composition retained in the dialysis tube was poured into a glass beaker, neutralized, and the smell and taste were evaluated. The composition after dialysis was compared with a sample treated by the same method but with a pH of 6.7 and another sample with neither dialysis nor pH adjustment. A blind evaluation conducted by several people showed that only the...

Embodiment 2

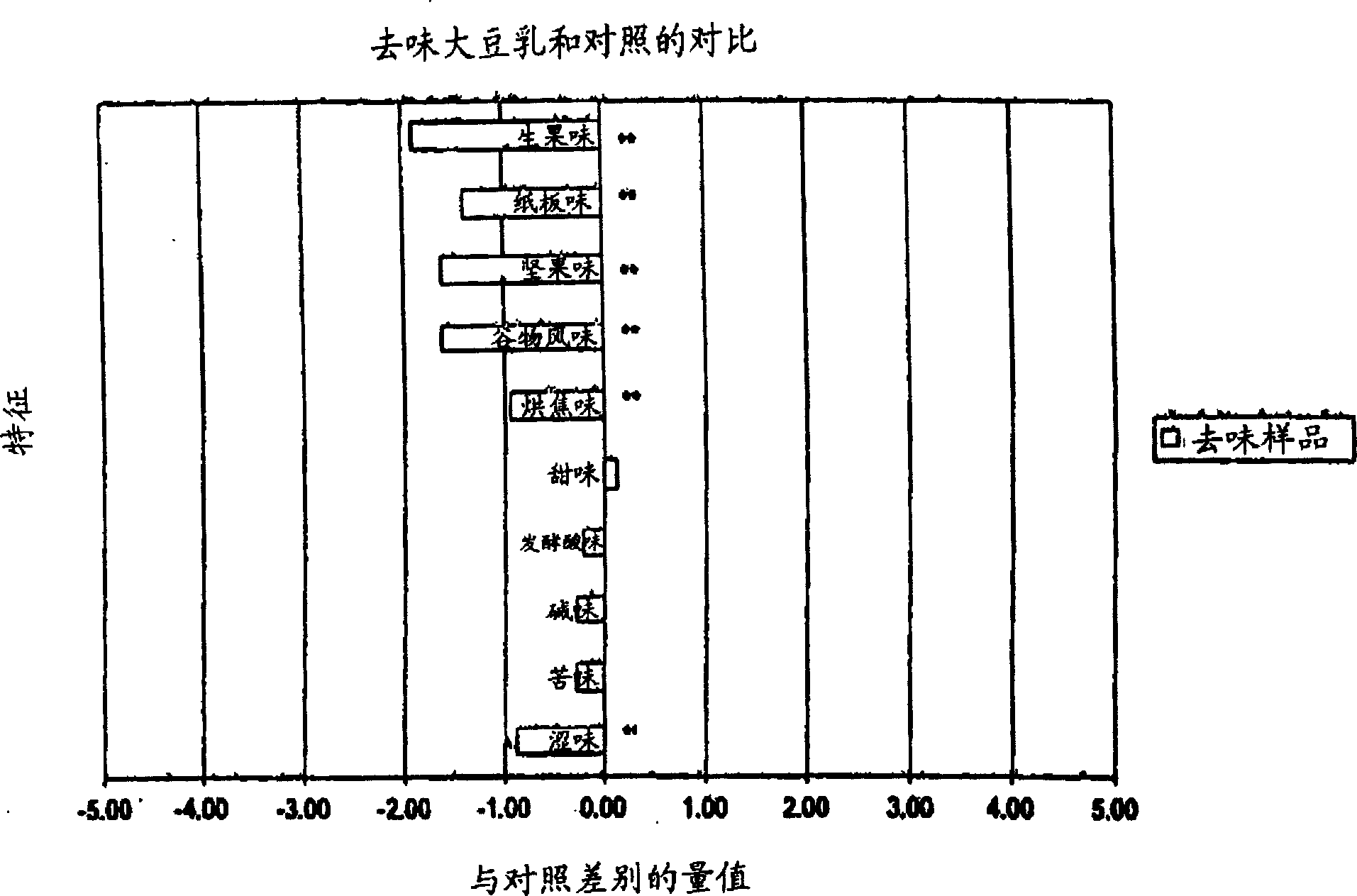

[0056] Example 2. Using soybean milk (Devansoy Farms, Carrol, Iowa) to make a 10% aqueous composition, perform a similar test, and then adjust the pH as in Example 1 and dialyze overnight. After treatment, the pH value of the sample was 8.8 and the smell and taste were significantly improved.

Embodiment 3

[0057] Example 3. Example 2 was repeated using fresh soybean milk prepared by soaking, bleaching and then grinding the soybeans and separating the soybean milk from the powder residue. As mentioned above, after adjusting the pH value and dialysis, it was found that the taste and smell of soy milk were significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com