Asymmetric type tank bottom bus and current distributing style

A technology of the bottom busbar and configuration method, which is applied to the installation of busbars, electrical components, cables, etc., can solve the problems of interface fluctuation, cannot be too far apart, and interfere with the normal production of electrolyzers, and achieves a small magnetic field gradient. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

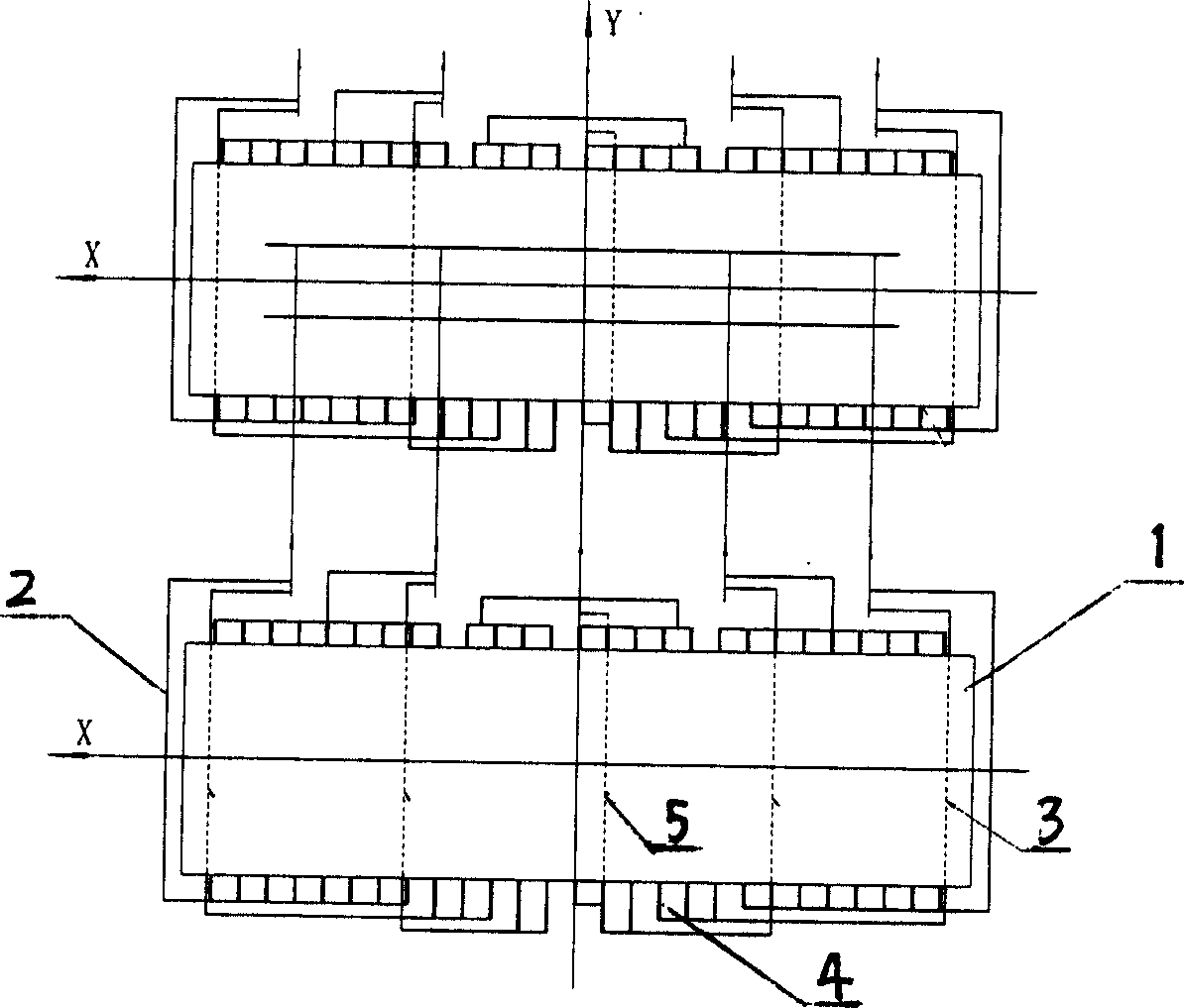

[0010] Embodiment of the present invention: 50% of the electric current of the electrolytic cell (1) flows out from 27 cathode soft busbars (4) on the power inlet side (the other 50% flows out from the cathode soft busbars on the power outlet side), and the electrolytic cell (1) longitudinal axis ( figure 1 Y-axis) as the center, the 3 slot bottom busbars (3) and the slot side busbars (2) near the flue end (right side) are connected 3 more than the 2 slot bottom busbars and the slot side busbars at the aluminum outlet (left side) One cathode soft busbar (4), so that the right busbar (3) at the bottom of the tank (3) flows into 3 more currents than the left side, and realizes the current asymmetrical configuration. The 3 bottom busbars (3) on the right are one more than the 2 busbars on the left, forming an asymmetric arrangement of the busbars at the bottom of the groove, and the first busbar (5) on the right side near the Y axis is arranged in At the first cathode flexible b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com