One-piece complaisant precision positioning platform in three degrees of freedom and parallel redundancy degree in single layer

A precision positioning and degree of freedom technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of increasing control difficulty and affecting work accuracy, and achieve the goal of increasing work flexibility, improving precision and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings of the description.

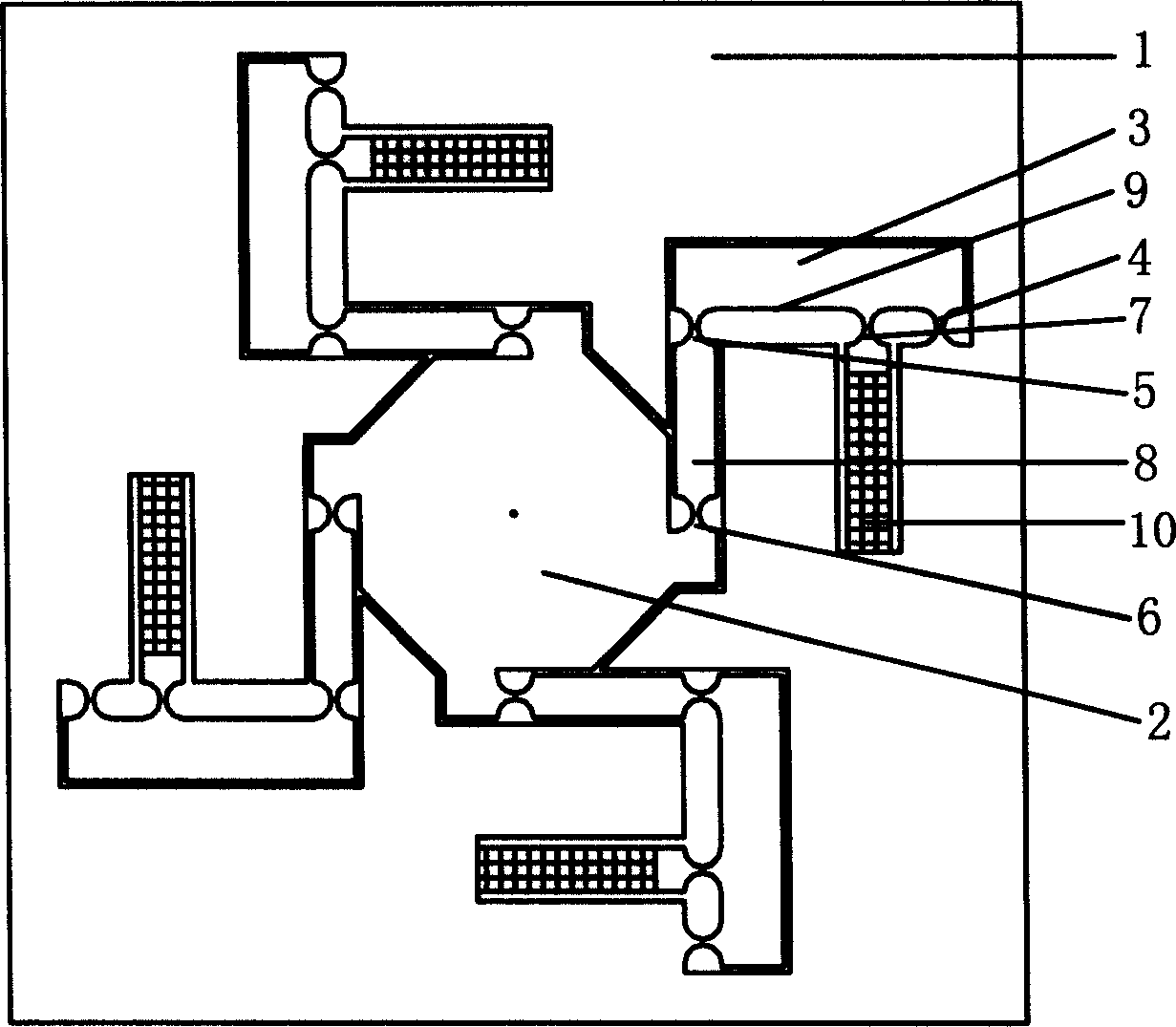

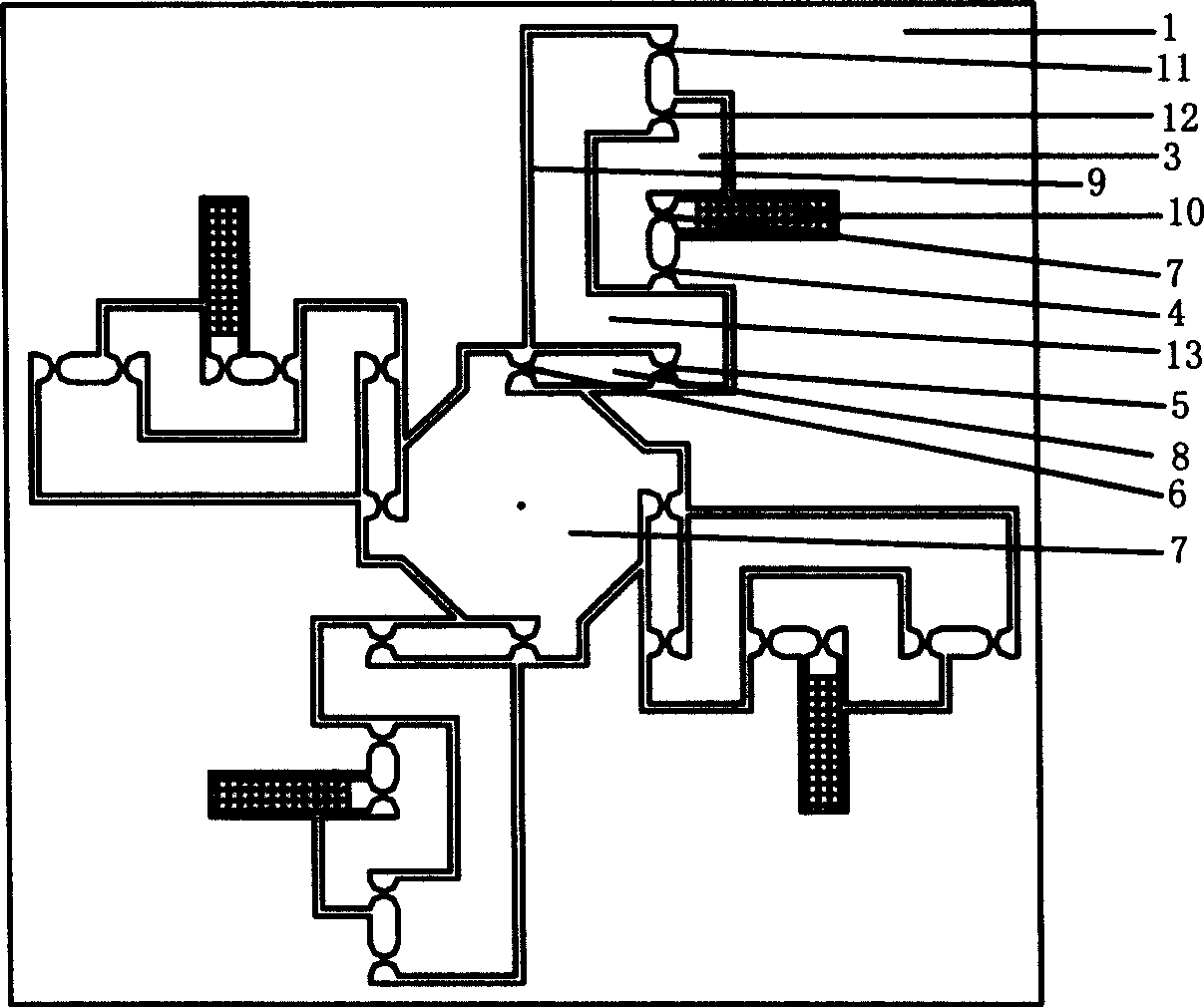

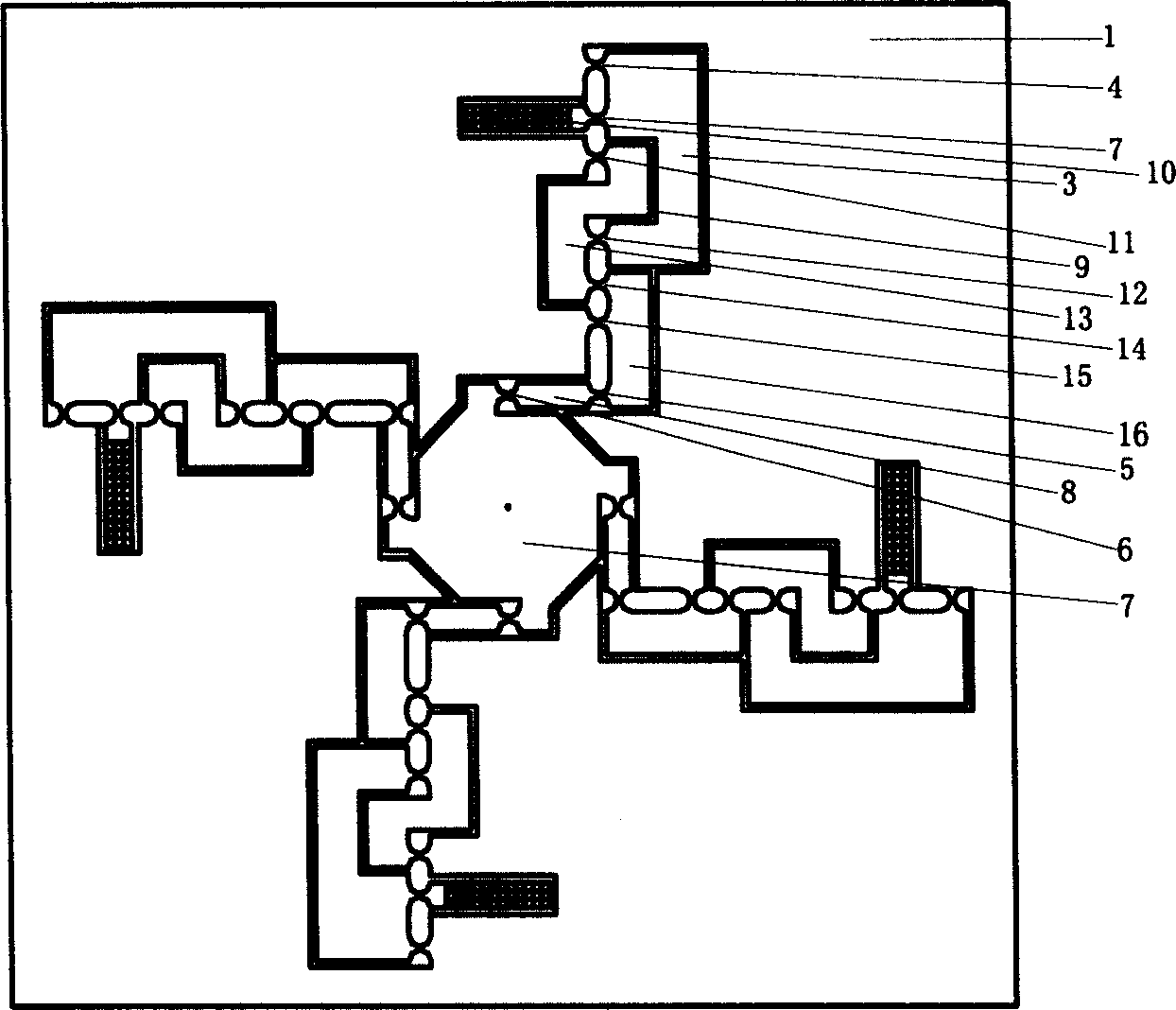

[0018] as attached figure 1 As shown, the present invention includes a motion platform 2 and a base 1, and is characterized in that four sets of displacement amplification mechanisms 9 are connected by flexible hinges between the motion platform 2 and the base 1; sides of the platform.

[0019] Described displacement amplifying mechanism 9 is made of active component 3, flexible hinge 4,5,6,7 and connecting rod 8; Active component 3 and base 1 of displacement amplifying mechanism 9 are connected by flexible hinge 4, active component 3 The connecting rod 8 of the amplification mechanism is connected by a flexible hinge 5 , the connecting rod 3 is connected with the telescopic brake 10 by a flexible hinge 7 , and the connecting rod 8 is connected with the motion platform 2 by another flexible hinge 6 .

[0020] The present invention adopts four sets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com