Opening structural computer digital control system able to re-configurate

An open structure, numerical control system technology, applied in the direction of computer control, general control system, control/adjustment system, etc., can solve the problems that new functions cannot be performed, the numerical control system cannot adapt to market demand, etc., and achieve the effect of ensuring robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

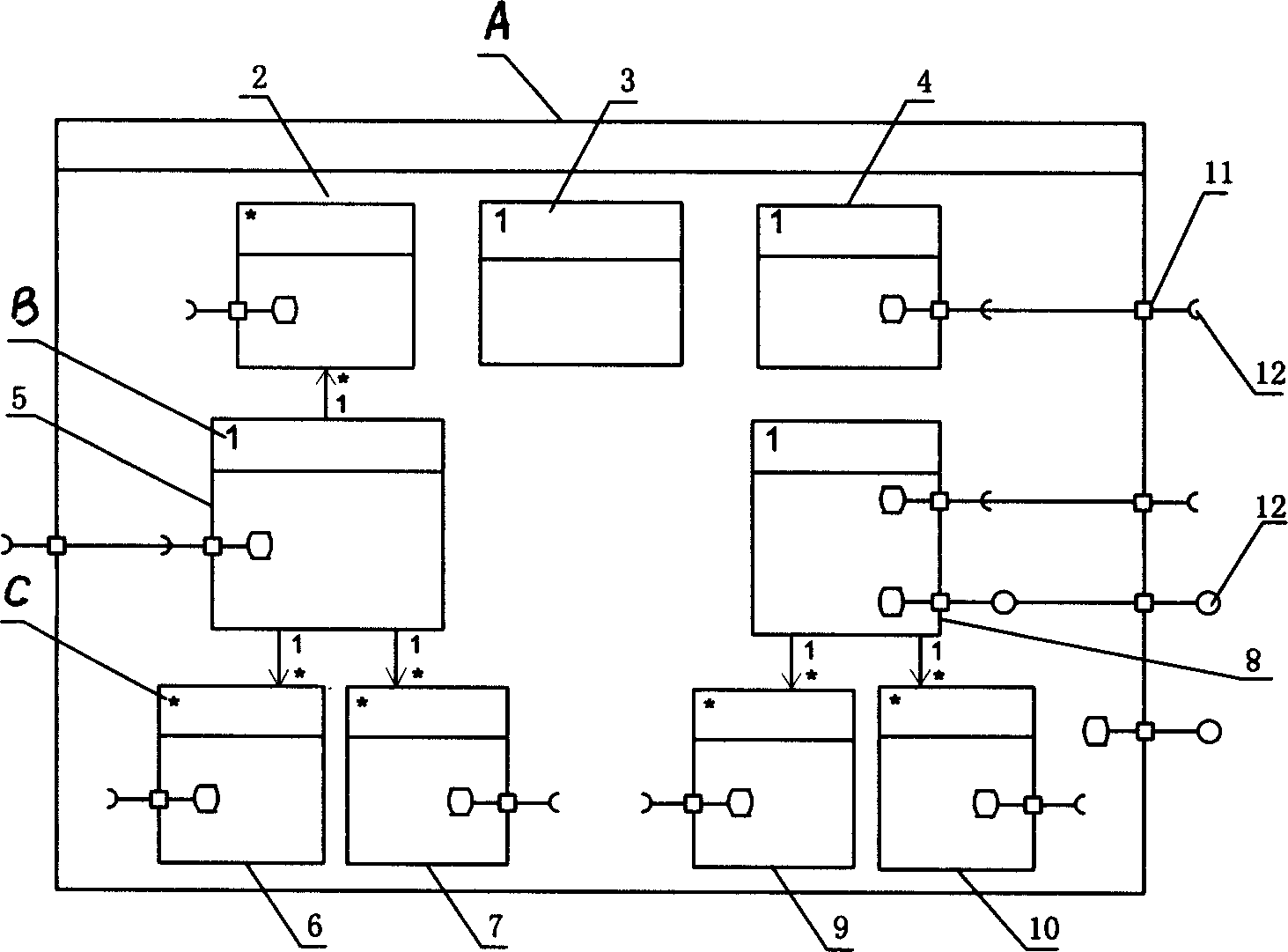

[0024] Such as figure 1 As shown, this example has

[0025] Motion axis and spindle coordination object module 8, this object module has a corresponding module instance: its function is responsible for dynamically creating the required number of motion axis object modules 9 and spindle object modules 10, and coordinating multiple motion axis object modules Synchronous motion control (such as X axis, Z axis, etc.), motion control of the main shaft, and synchronous control of the motion axis and the main shaft;

[0026] Auxiliary device object coordination module 5, which has a corresponding module instance: its function is to dynamically create the required number of external auxiliary device object modules, which includes IO device object module 2, AD device object module 6, DA The equipment object module 7, and coordinate these modules to realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com