Diaphragm pump structure for improving assembling reliability

A diaphragm pump and diaphragm technology, applied in the field of improved structure of the diaphragm pump, can solve the problems of easy loosening from the body 7, wear and installation of the diaphragm pump 11, and difficulty in separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

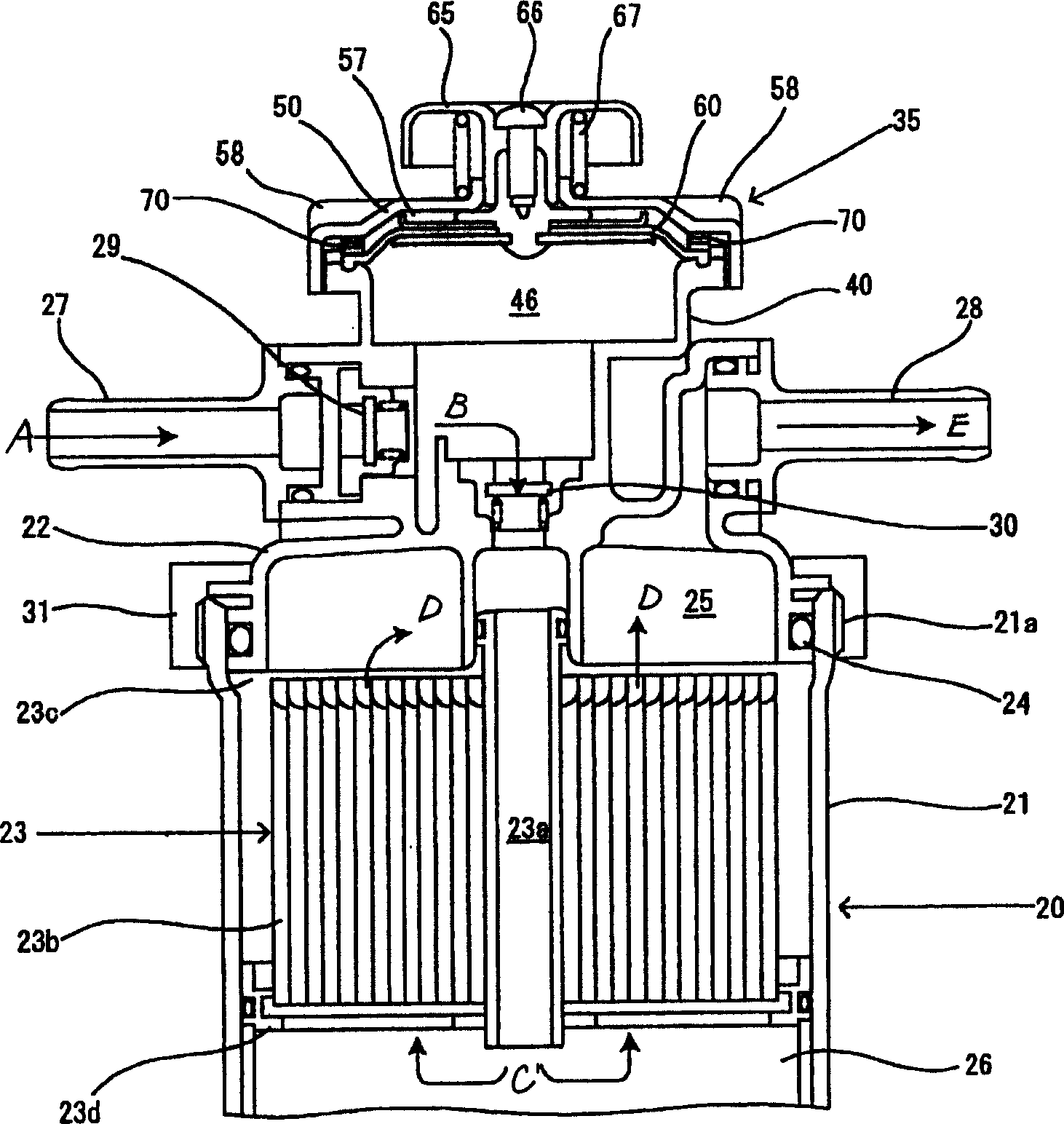

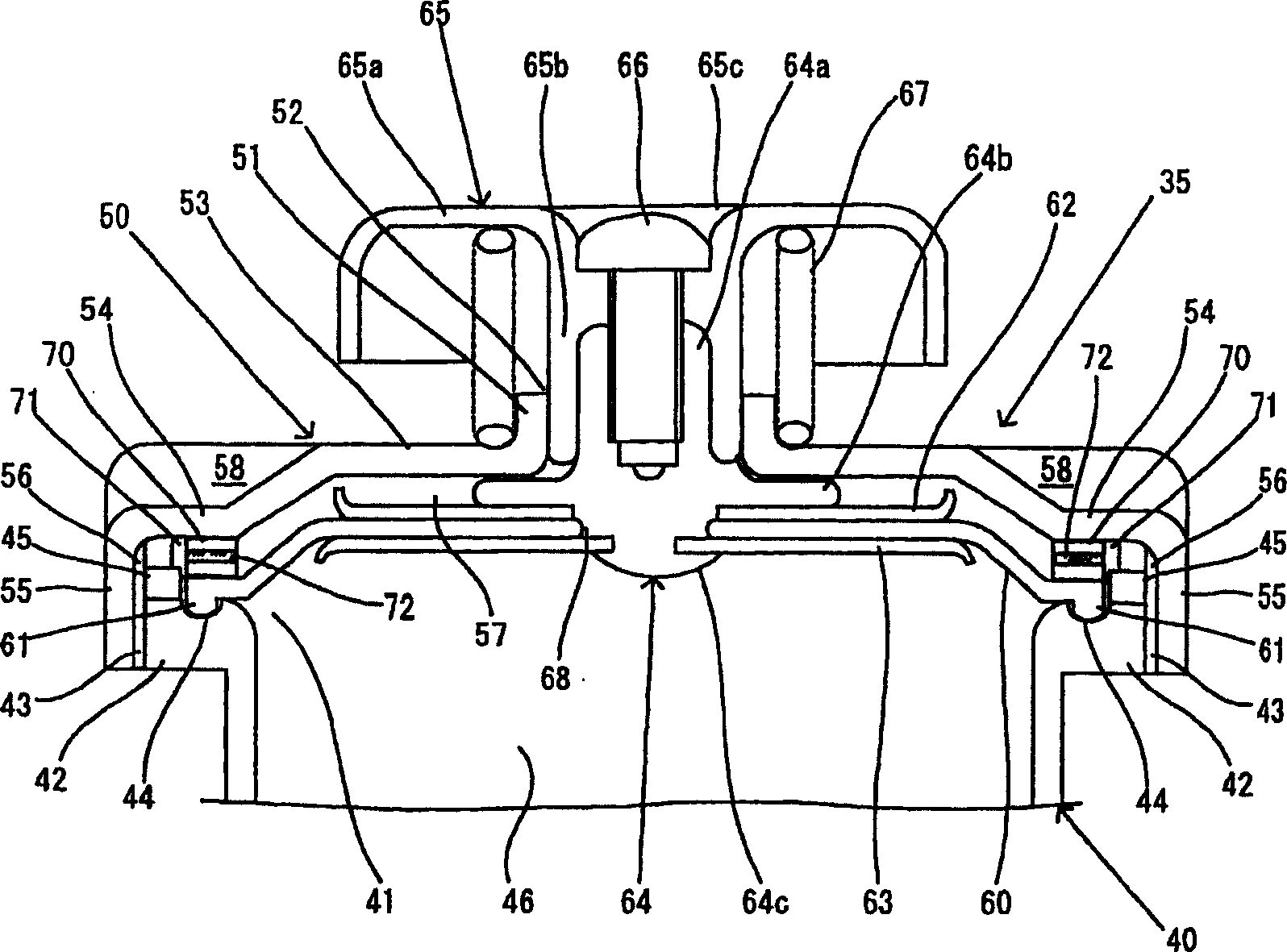

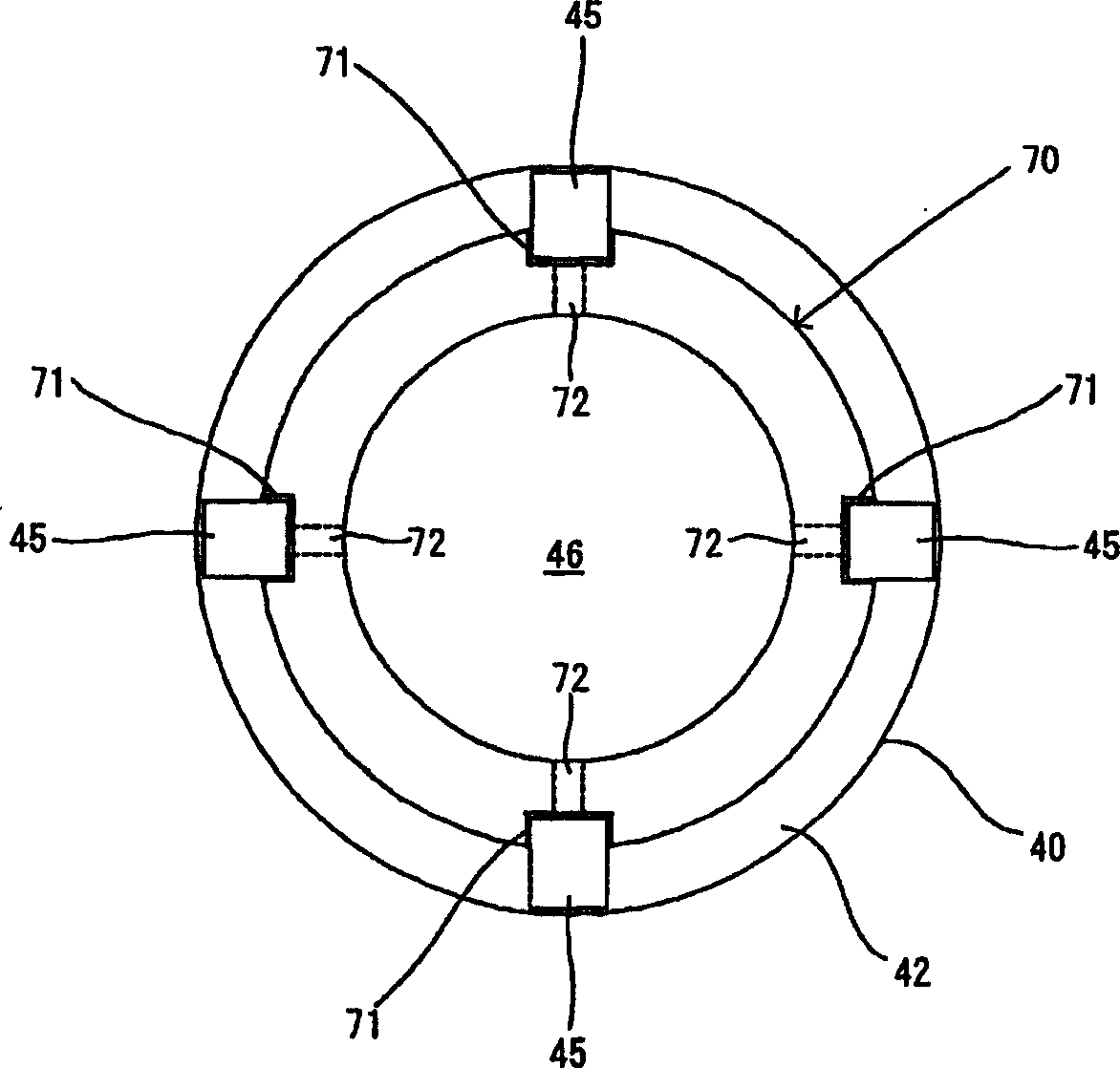

[0041] Referring to the drawings, in which like reference numerals designate like parts throughout the several views, and in particular figure 1 , which shows a diaphragm pump 35 provided with a diesel filter 20 according to the invention, which can be installed in the fuel system of an automotive diesel engine.

[0042] The diesel filter 20 includes a cup-shaped housing 21 defining an outer shell, a cap 22 detachably mounted at an open end of the housing 21 , and a filter device 23 placed inside the housing 21 .

[0043] The casing 21 is made of a resinous hollow cylinder with an upper opening. On the outer circumference of the upper end of the housing 21, a thread 21a is cut.

[0044] The filter device 23 is composed of a fuel path pipe 23a, a filter element 23b, an upper end plate 23c with holes (not shown) and a lower end plate 23d with holes (not shown), wherein the fuel path pipe 23a is coaxial with the The rolled sheet (or sheets) forms the filter element 23b. A fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com