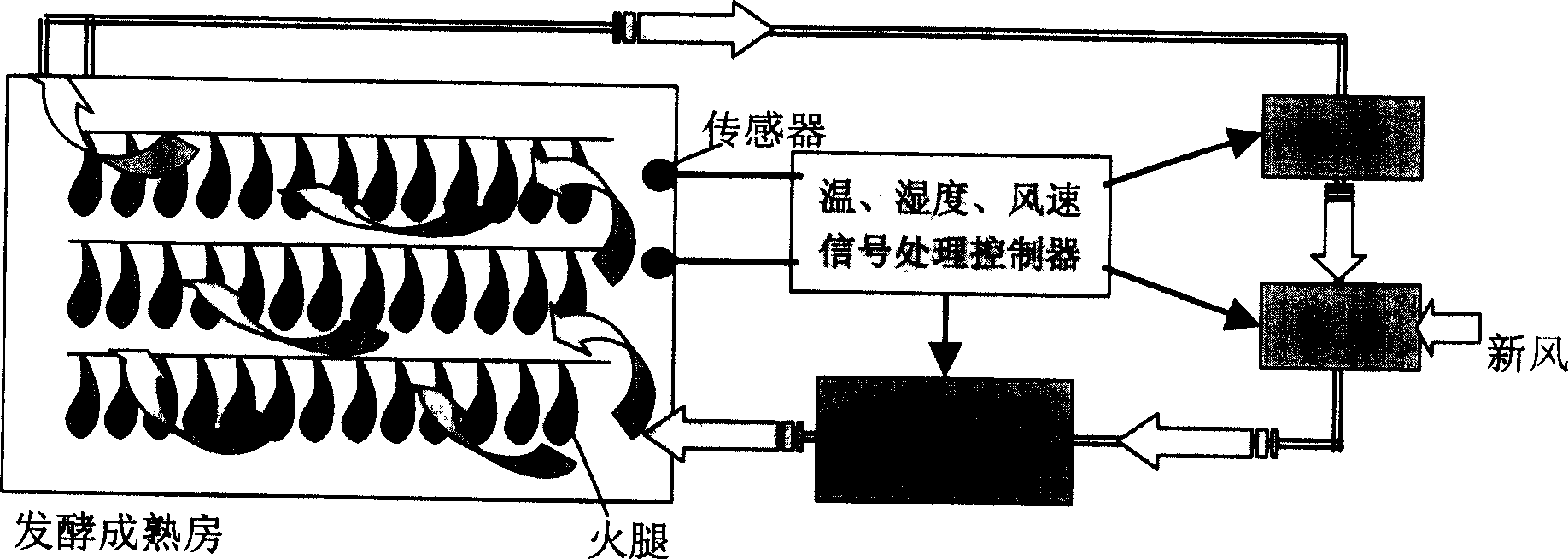

Ferment and mature process of dried pickled ham

A technology for fermenting mature, dry-cured ham, applied in food preservation, climate change adaptation, meat/fish preservation, etc. The effect of modern and intelligent control, shortening process time, breaking through seasonal constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The dry-cured pork legs that have been soaked, rinsed and dried are hung on the shelves of the fermentation maturation room according to a certain distance, and then enter the fermentation maturation process after being dehydrated at 10-16°C for 3-10 days; the temperature range of medium-temperature fermentation is 16 -30°C, the time is 30-60 days; the temperature range for high-temperature maturation is 30-40°C, the time is 30-50 days, of which the high temperature time of 35-40°C is controlled at more than 20 days; the daily temperature during the fermentation and maturation process The rise and fall simulates the natural process, the set temperature value is lowered by 5±3°C, and the low temperature is maintained for 6-10 hours at night; during the medium-temperature fermentation process, the fresh air volume entering the fermentation maturation room gradually increases from zero to 30-40%, and the relative humidity is at In the range of 80%RH-30%RH, it gradually decr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com