Vane structure of vertical axis wind-driven motor and speed stablizing apparatus thereof

A wind engine and wind blade technology, applied in the direction of wind engine, installation/supporting configuration of wind engine, wind turbine components, etc., can solve the problem of unreasonable structure of wind blade, low generator, unsteady speed of large wind turbine, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

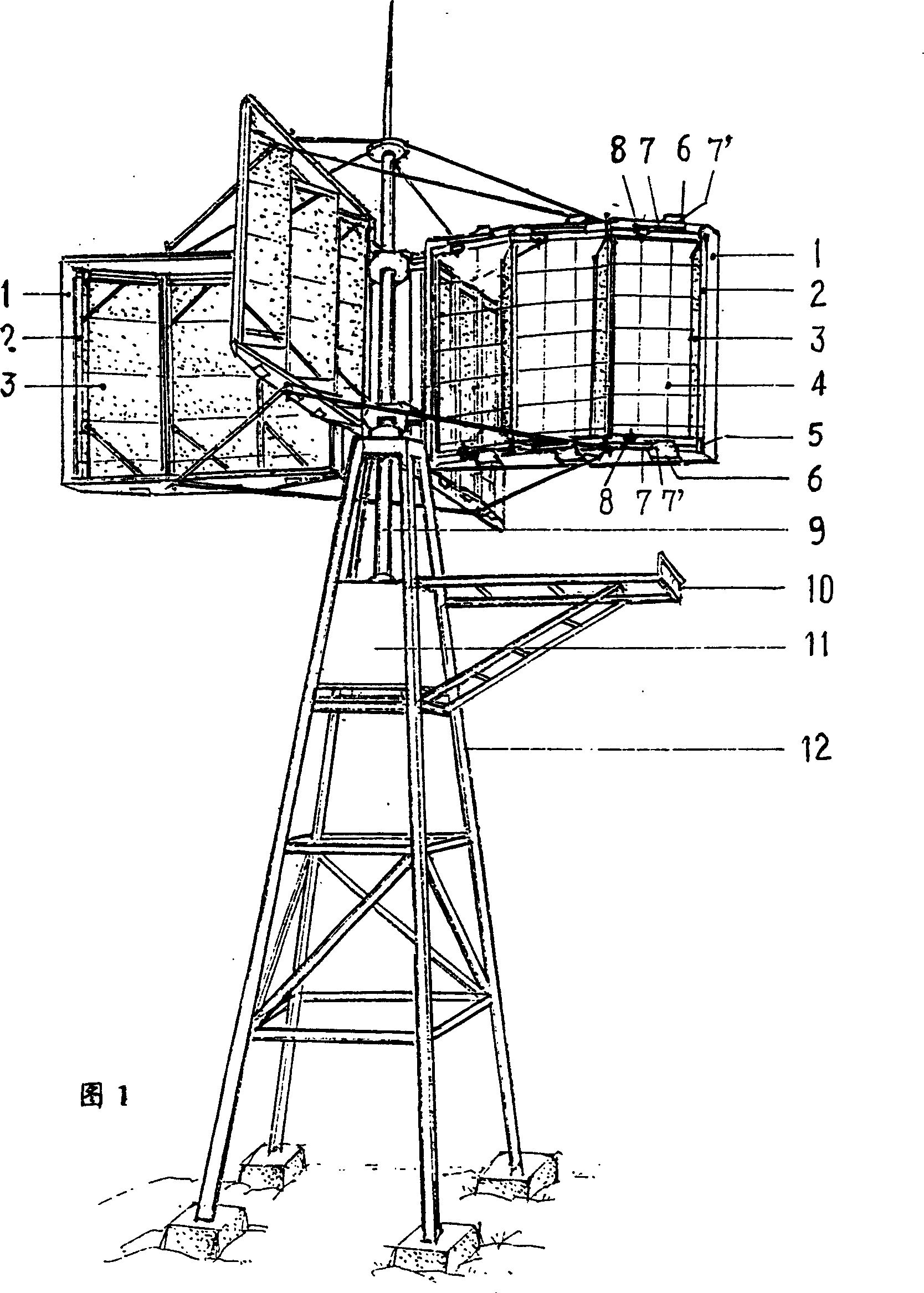

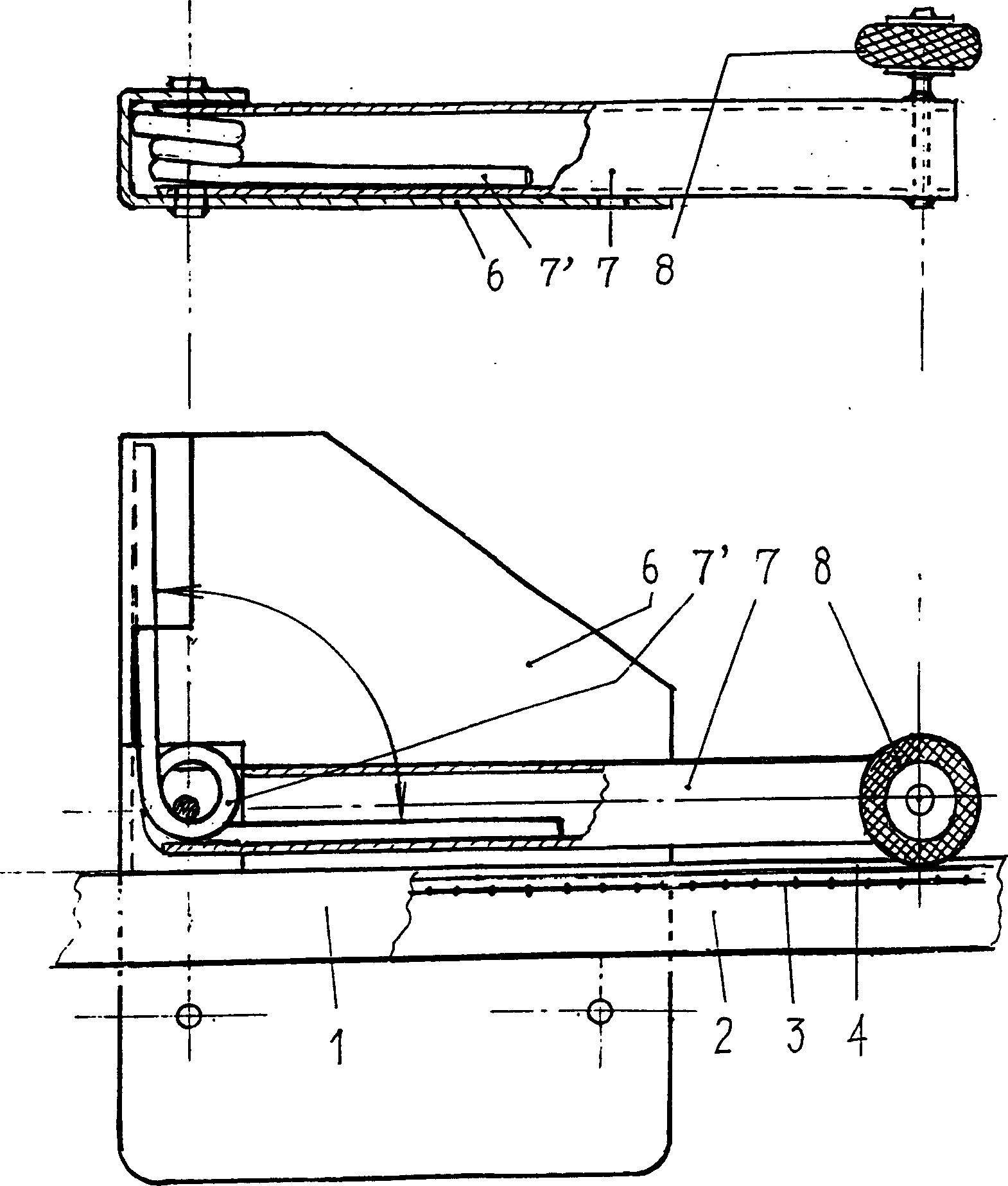

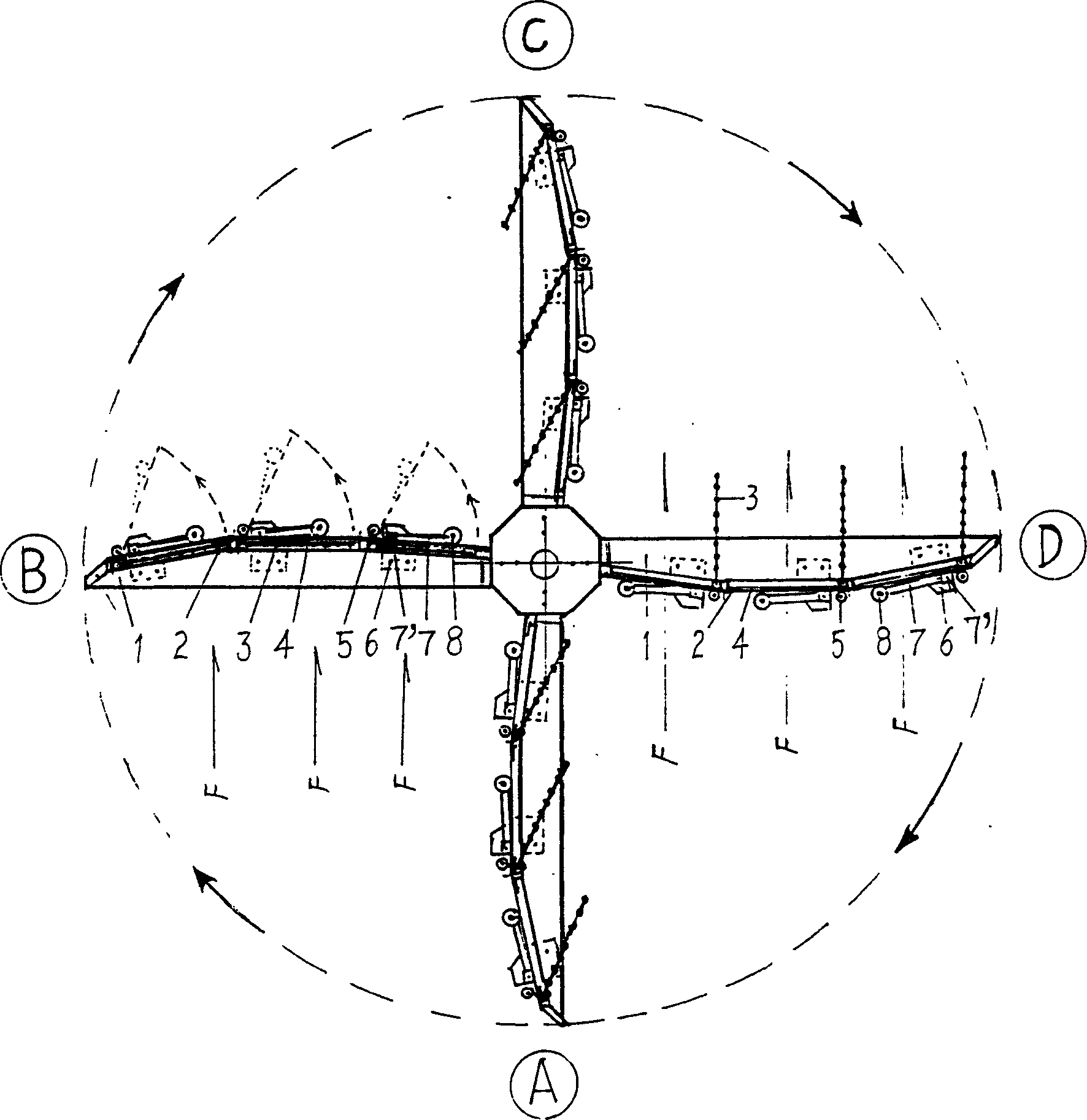

[0020] As shown in Fig. 1, the present invention is a fan blade structure and a speed-stabilizing device specially designed for vertical-axis movable blade wind turbines. Several small wind blade frames 2 are housed in each large wind blade frame 1, and the small wind blade frame shaft 5 is connected with the large wind blade frame 1 on the upper and lower sides of a mullion on the outside of the small wind blade frame 2 away from the main shaft 9 of the wind turbine. The inner side of the small fan blade frame 2 facing the wind-receiving facade is provided with movable small blades 3 and is connected with the small fan blade frame 2 with the second small shaft on the upper and lower sides of the inside of the vertical frame, and the movable small blades 3 can be wound around The second small axial small blade frame 2 rotates towards the inside of the wind-receiving facade to form the open and closed states of the wind blades. The small wind blade frame 2 is provided with a sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com