Rolling control device and rolling control method

A technology of a control device and a control method, which is applied to the rolling mill control device, rolling force/roll gap control, metal rolling, etc., can solve the problem that the plate thickness offset cannot be removed from the exit side, the offset cannot be eliminated, and the exit side cannot be eliminated. Plate thickness offset and other problems, to achieve the effect of reducing the actual unqualified length and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

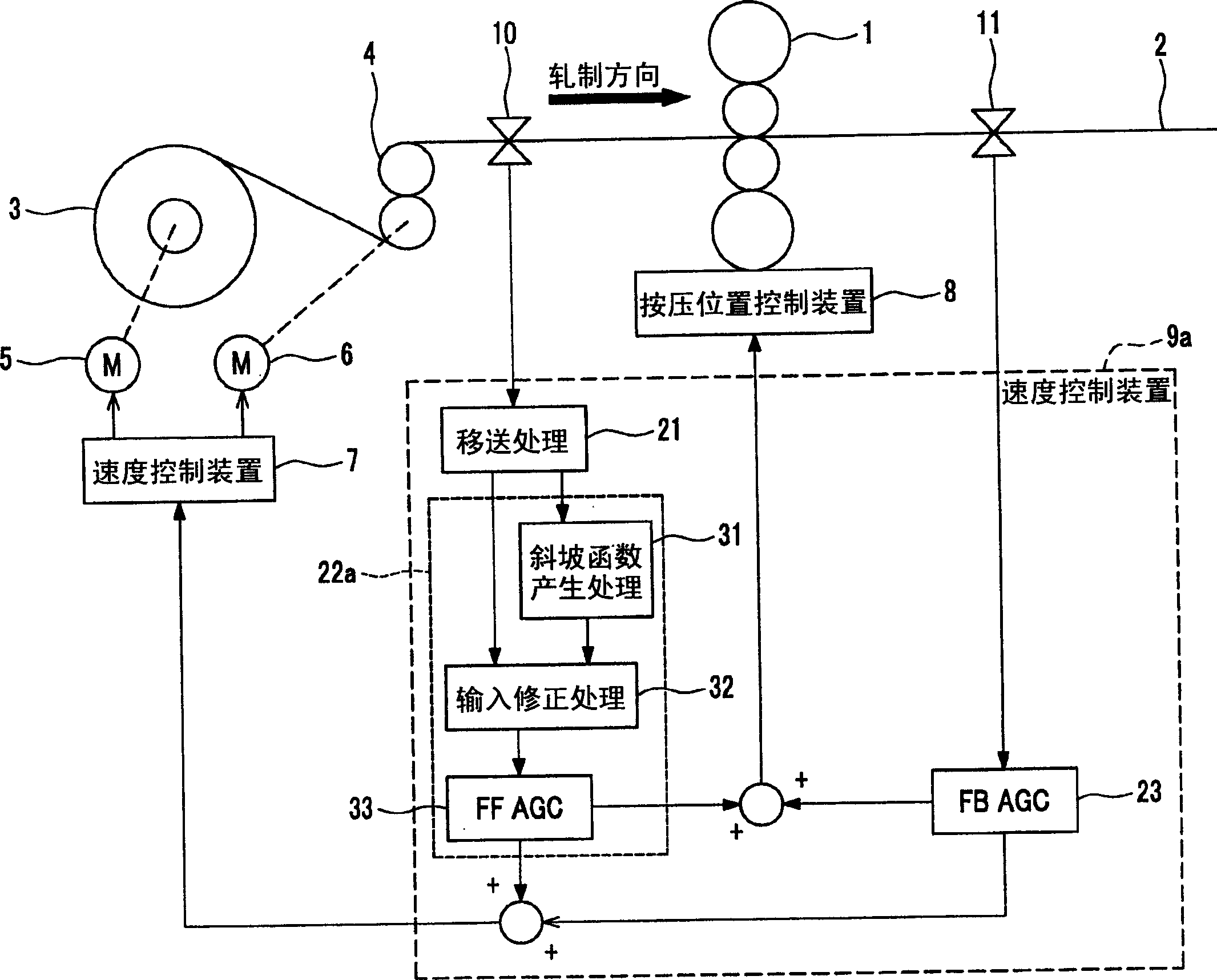

[0025] figure 1 It is a figure which shows the block structure of the thickness control system of the rolling mill in the prior art.

[0026] In the rolling mill, a rolling mill 1, a tension reel (tension reel) 3 and a tension roll (bridle roll) 4 are provided. The side tension coiler 3 (not shown) and tension roll 4 (not shown) are transferred from the entry side to the exit side, and rolling is performed while applying a load by the rolling mill 1 . Moreover, the speed control device 7 controls the rolling speed of the entry side and the exit side of the rolled material 2 by controlling the rotational speeds of the motors 5 and 6 respectively driving the tension coiler 3 and the tension roll 4, and controls the pressing position. The device 8 controls the load applied to the material to be rolled 2 by changing the pressing position (roll gap) of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com