Elevator cable brake

A main cable and brake technology, which is applied in the hoisting device and other directions, can solve the problems of increased volume of elastic elements, difficulty in recovery, and increased cost, and achieve the effects of easy triggering, easy recovery, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

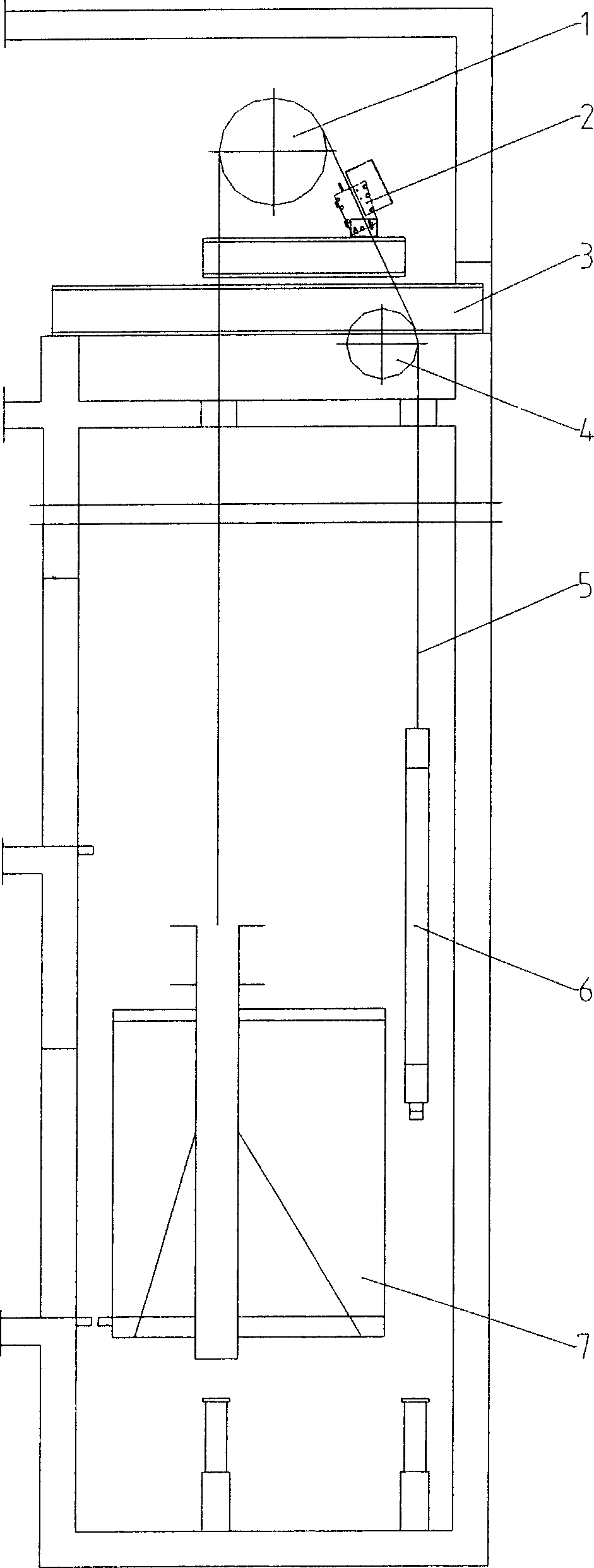

[0029] An example of the present invention is figure 1 As shown, the elevator car 7 and the counterweight 6 are suspended by the main steel cable 5, and vertically move up and down along the car guide rail and the counterweight guide rail respectively. One end of the elevator main steel cable 5 is connected to the car 7 and keeps It extends to the machine room, bypasses the traction sheave 1, then passes through the main cable brake 2, then walks around the guide wheel 4, passes out of the machine room and enters the hoistway, and the other end is connected to the top of the counterweight 6. In addition, the main cable brake 2 can also be installed vertically under the guide pulley 4 , and can also be installed vertically under the traction sheave 1 .

[0030] In addition to the 1:1 winding method of the elevator main rope 5 as mentioned above, the 2:1 winding method is also included.

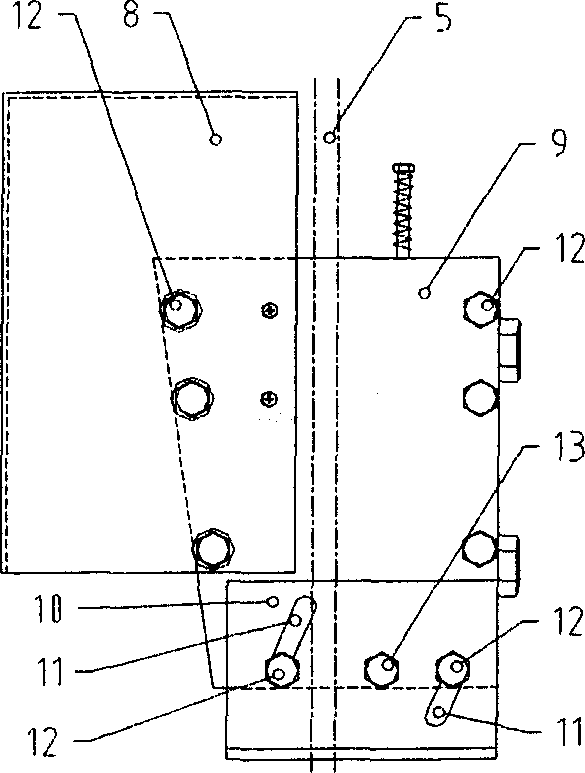

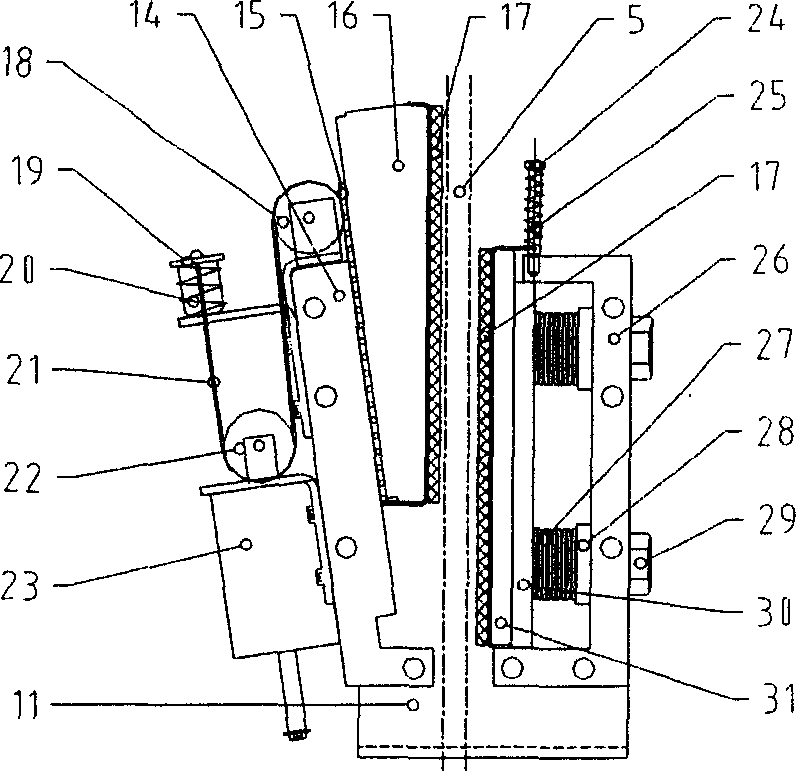

[0031] figure 2 It is the front view of the present invention before action. The connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com