Winding wiring structure for ultra-large capacity on-load variac

A voltage regulating transformer and voltage regulating winding technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problem of high oscillation potential of voltage regulating winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

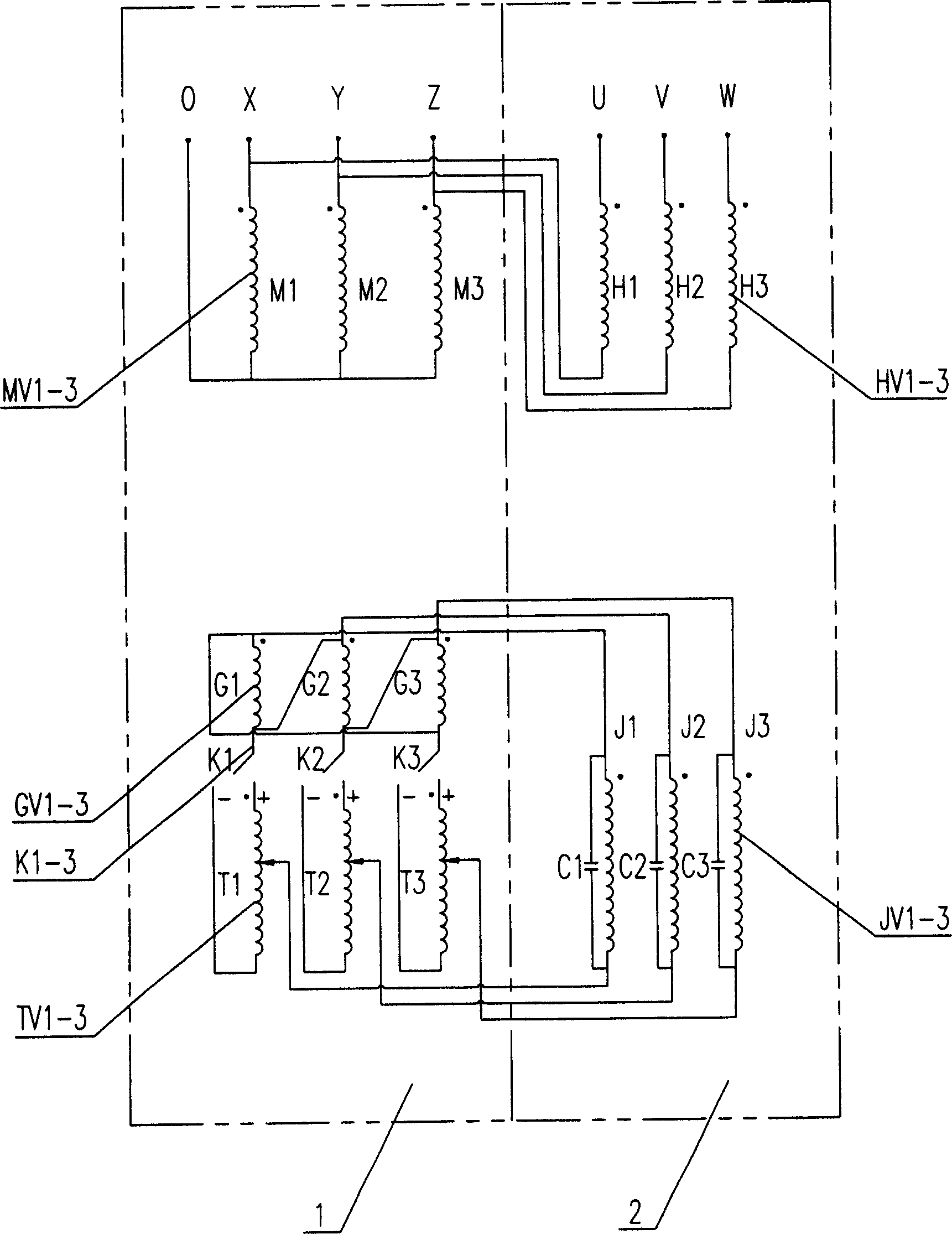

[0011] According to the winding structure of the ultra-large capacity self-coupling on-load transformer of the present invention, a 900MVA auto-coupling on-load voltage regulating transformer is designed, and its winding circuit structure is as attached figure 1 shown. M of common winding MV1-3 1 , M 2 , M 3 Three coils, G of GV1-3 of excitation winding I 1 , G 2 , G 3 T of the three coils and the voltage regulating winding TV1-3 1 , T 2 , T 3 The three coils are sequentially set on the three iron core columns of the constant flux device body, forming the constant flux device body—the public transformer (M transformer). While the H of the series winding HV1-3 1 、H 2 、H 3 Three coils with field winding II JV1-3 J 1 、J 2 、J 3 The three coils are successively set on the three iron core columns of the flux transformer body, forming the flux transformer body—series transformer (S transformer). The two bodies are installed together in the transformer oil tank.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com