Spinning reel sounding mechanism

一种绕线轮、构件的技术,应用在钓鱼用绕线轮、捕鱼、应用等方向,能够解决不能获得清脆的声音、妨碍卷筒平稳转动等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

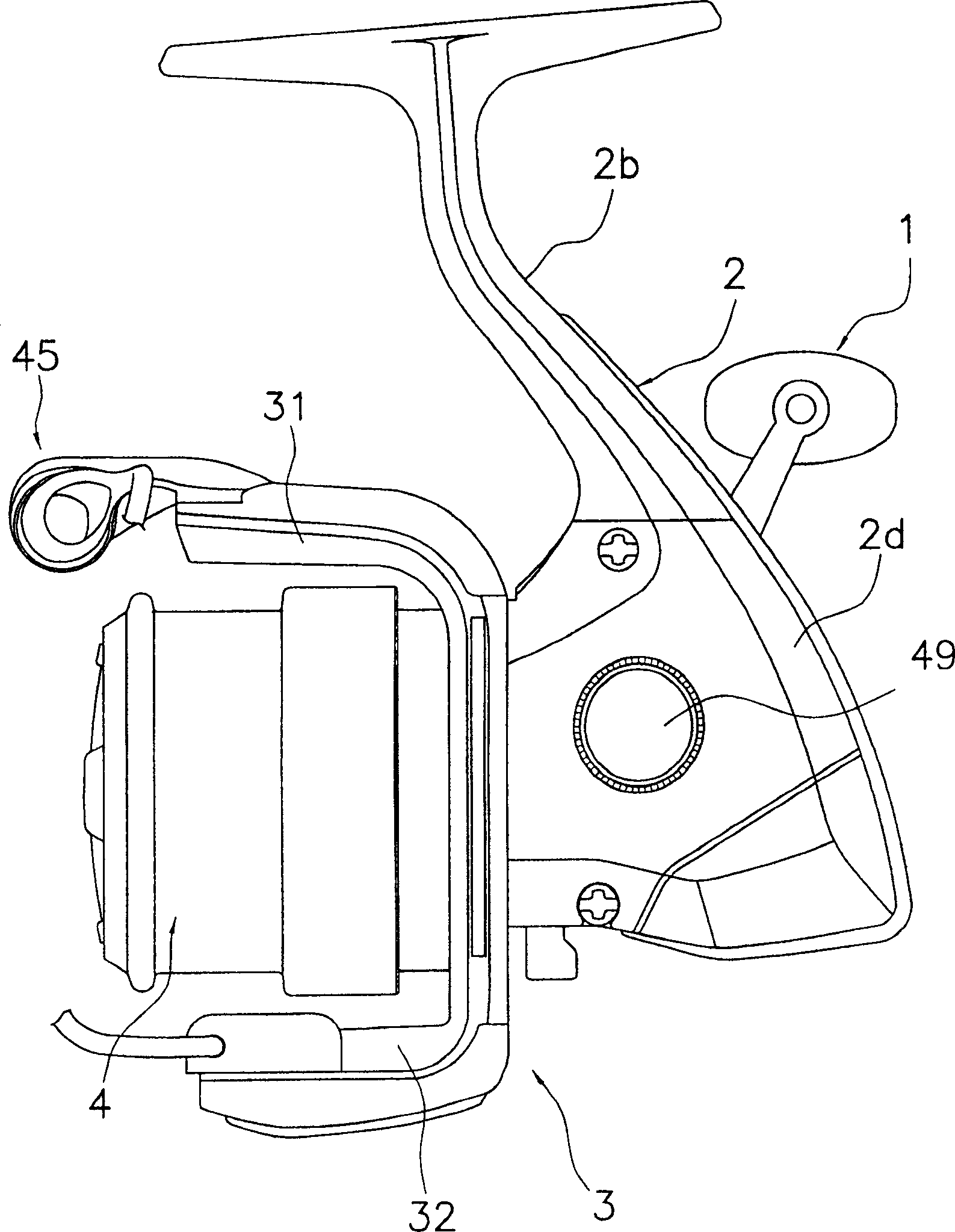

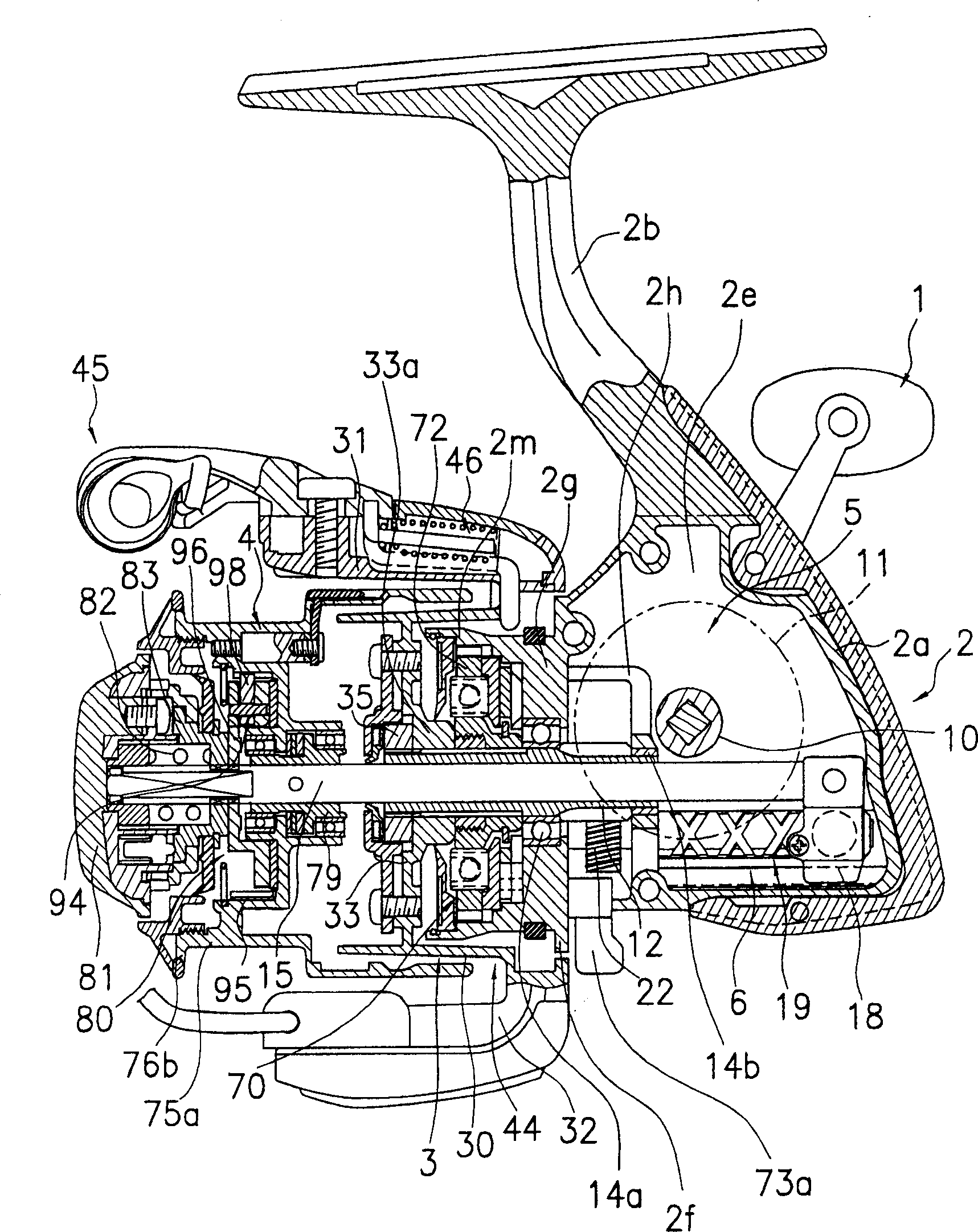

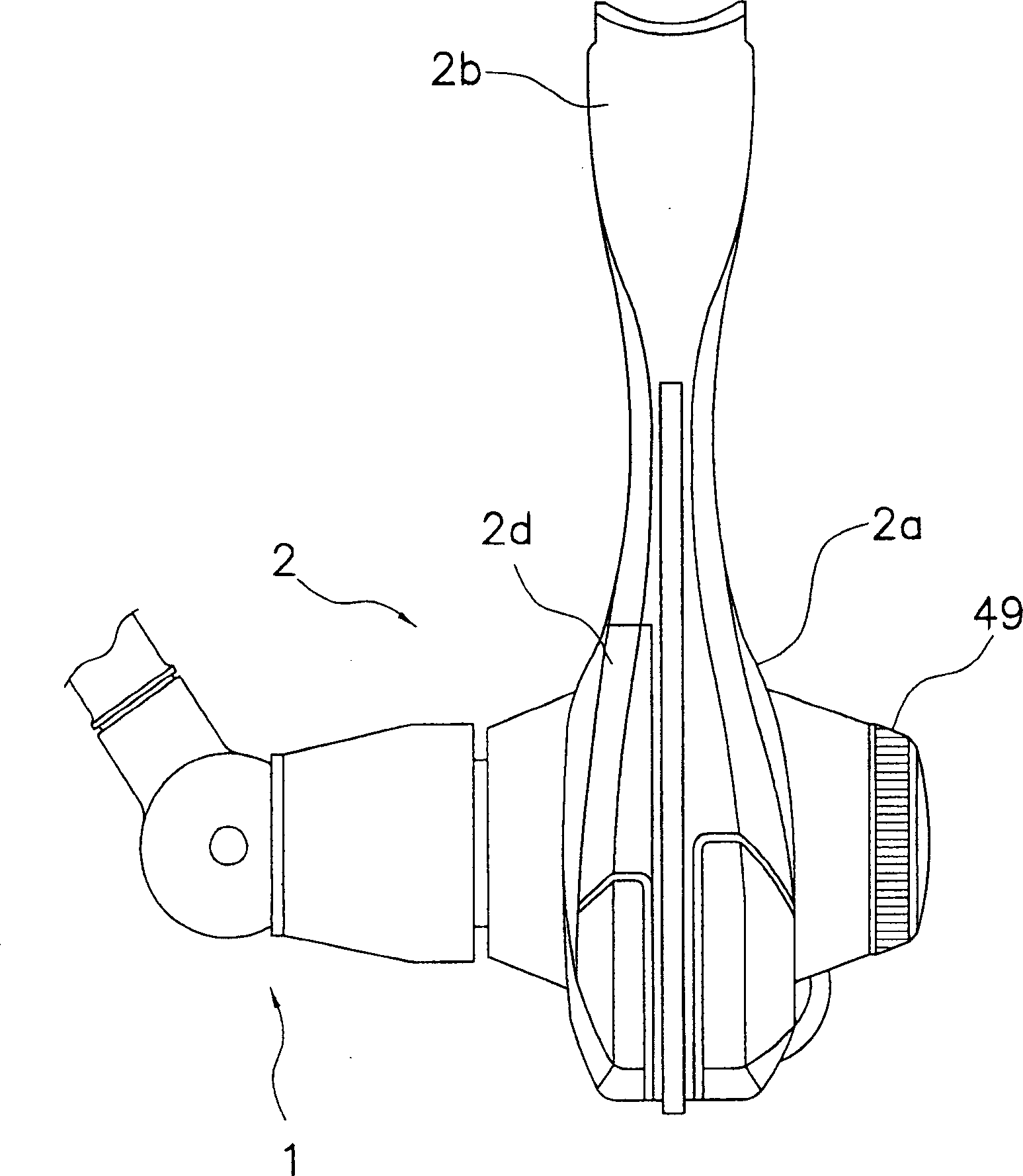

[0048] Selected embodiments of the present invention will now be described with reference to the drawings. It will be understood by those skilled in the art from this specification that the following description of the embodiments of the present invention is for illustrative purposes only, and is not intended to limit the present invention. The present invention is defined by the appended claims and their equivalents.

[0049] Such as figure 1 with 2 As shown, the rotating reel according to the embodiment of the present invention is adopted, including a handle 1, a reel unit 2 rotatably supporting the handle 1, a rotor 3, and a reel 4. The rotor 3 is rotatably supported on the front part of the reel unit 2. The reel 4 makes the fishing line wind around its outer peripheral surface and is arranged on the front of the rotor 3 so that the reel 4 can move back and forth. Noticed as figure 1 with 2 As shown, the crank 1 is installed on the right side, and the crank cover 49 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com