Compound instrument piece for musical bar instrument and manufacturing method thereof

A sound bar and piano piece technology, applied in the field of musical instruments, can solve the problems of unenvironmental protection, inaccurate scale, short sustain, etc., and achieve the effects of simple production process, stable scale and crisp sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

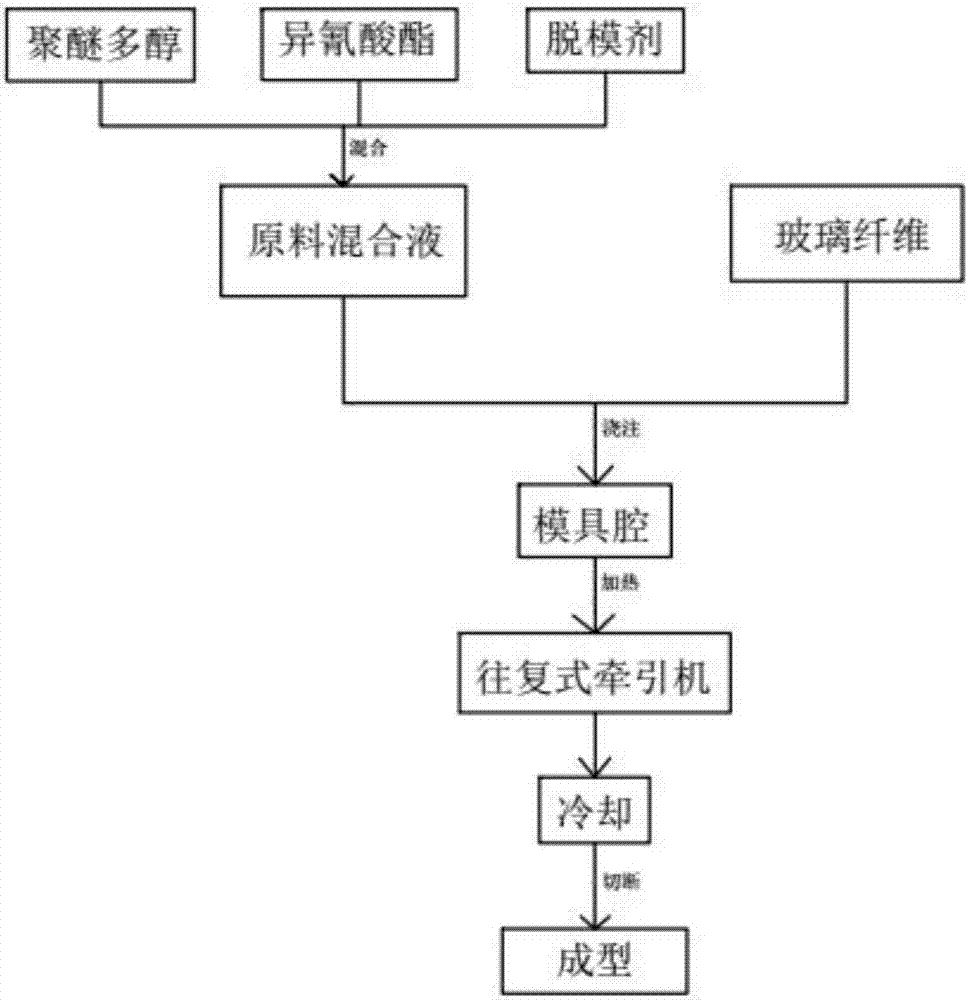

[0049] Thread 75% glass fiber raw material into the mold;

[0050] Inject 8% polyether polyol, 3% isocyanate, and 14% release agent into the raw material barrel to form a raw material mixture;

[0051] Pump the mixed raw material mixture in the raw material barrel into the injection gun;

[0052] The injection gun pours the mixed raw material mixture on the 75% glass fiber;

[0053] The glass fiber fully impregnated with the raw material mixture enters the heating cavity of the mold, and the heating temperature is 100°C-120°C;

[0054] The glass fiber impregnated with the raw material mixture is heated and solidified in the mold cavity;

[0055] The formed product is pulled out of the mold by a hydraulic reciprocating tractor, and the finished product is cooled;

[0056] Cut according to the length requirements of the product.

Embodiment 2

[0058] Thread 80% glass fiber raw material into the mold;

[0059] Inject 5% polyether polyol, 10% isocyanate, and 5% release agent into the raw material barrel to form a raw material mixture;

[0060] Pump the mixed raw material mixture in the raw material barrel into the injection gun;

[0061] The injection gun pours the mixed raw material mixture on the 80% glass fiber;

[0062] The glass fiber fully impregnated with the raw material mixture enters the heating cavity of the mold, and the heating temperature is 100°C-120°C;

[0063] The glass fiber impregnated with the raw material mixture is heated and solidified in the mold cavity;

[0064] The formed product is pulled out of the mold by a hydraulic reciprocating tractor, and the finished product is cooled;

[0065] Cut according to the length requirements of the product.

[0066] The synthesized violin piece prepared by the invention has clear and crisp sound, long sustain and good sound quality, can completely repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com