Reflector and light source apparatus having reflector

A reflective mirror and reflective surface technology, which is applied in the field of reflective mirrors, can solve problems such as reflection and inability to perform the function of reflective mirrors, and achieve efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

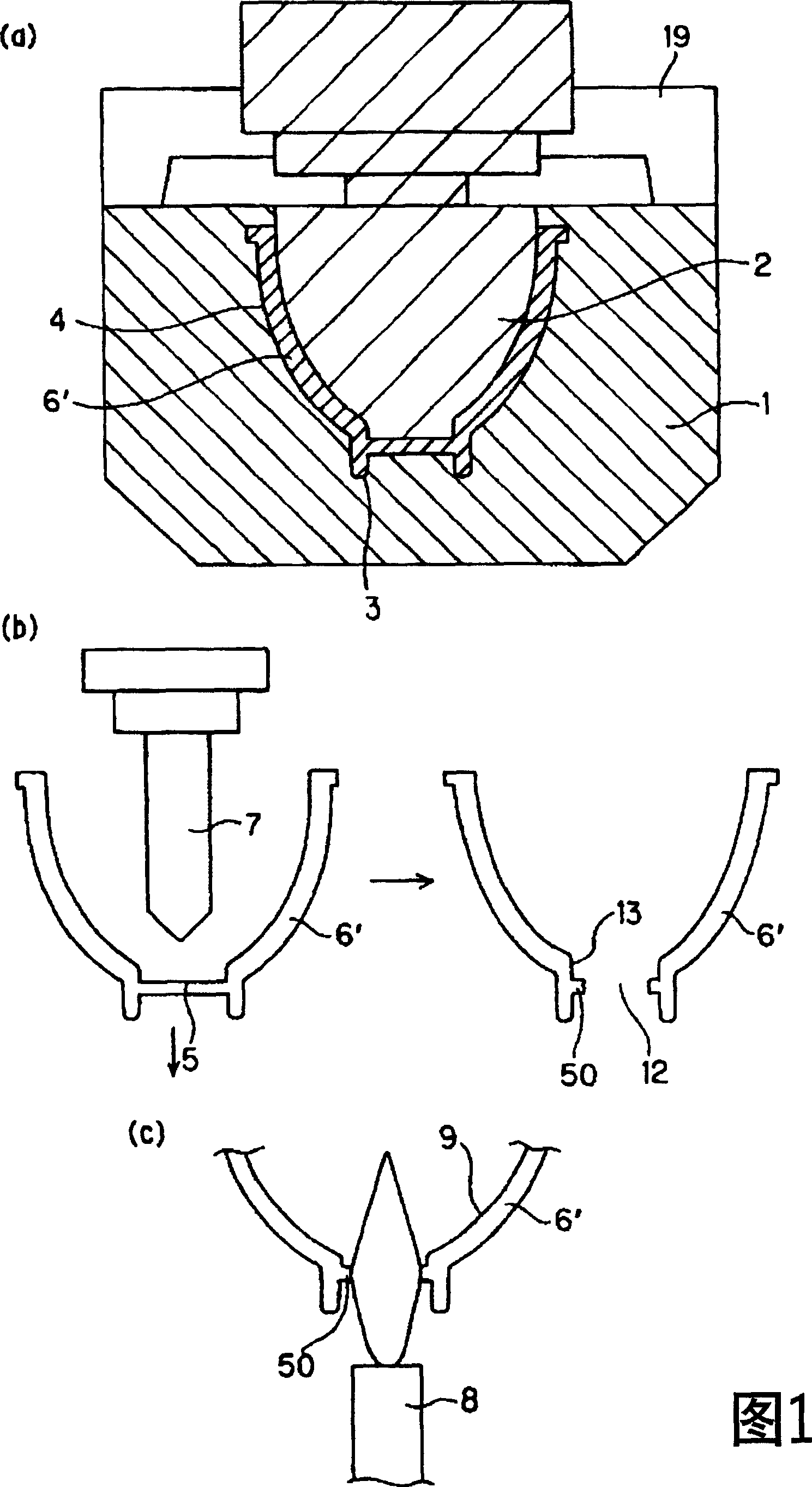

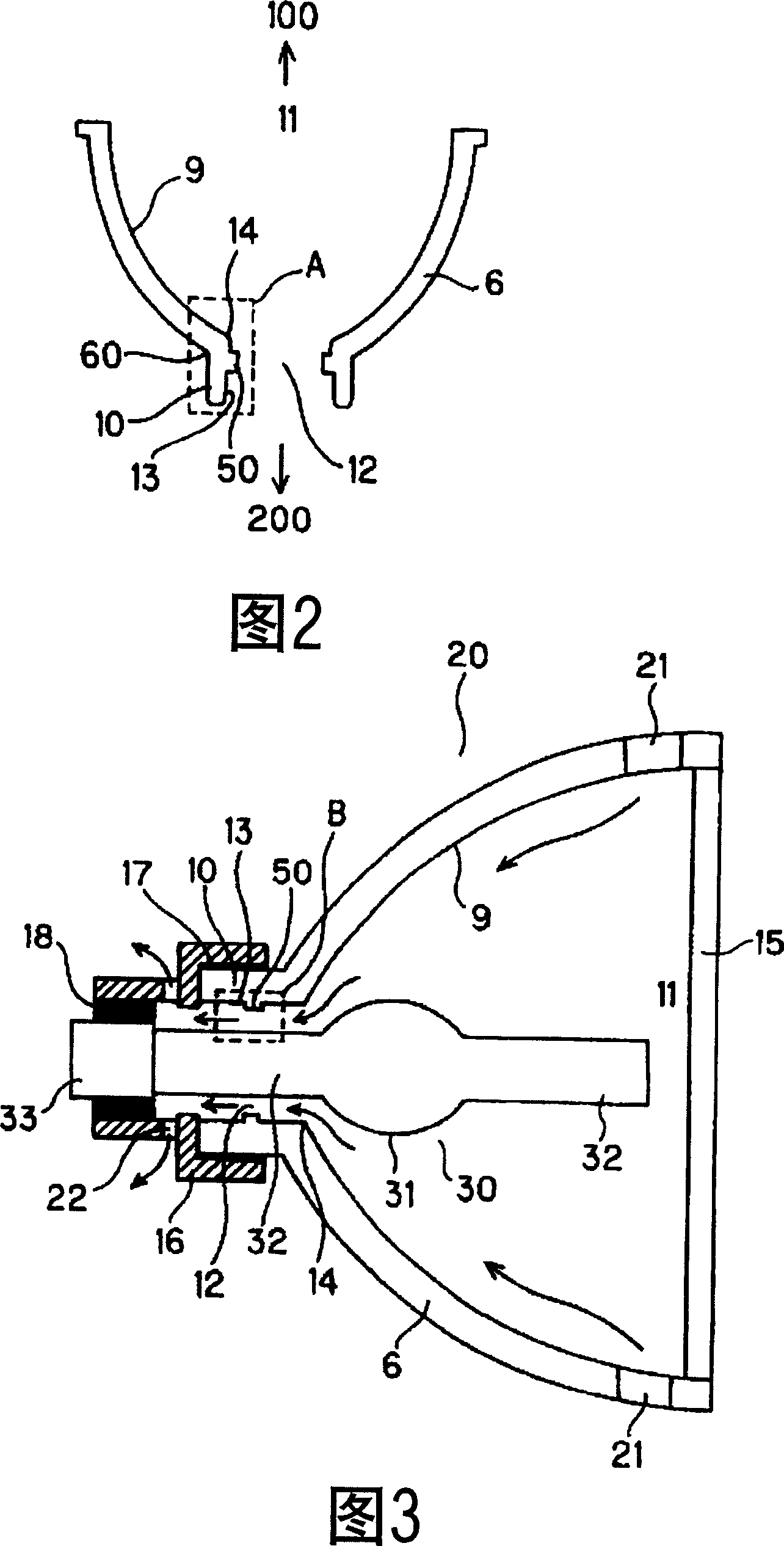

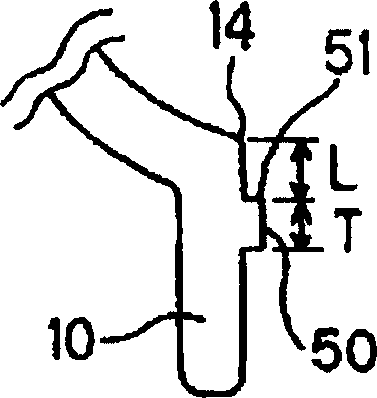

[0033] FIG. 1 is a diagram for explaining a method of manufacturing a reflecting mirror according to the present invention. As shown in FIG. 1 , the reflecting mirror according to the present invention is produced through the first to fourth steps.

[0034]

[0035] As shown in FIG. 1( a ), the female mold 1 has a concave portion suitable for the shape of the mirror to be molded, and has a neck hole 3 forming the neck of the mirror on the bottom of the concave portion. Molten borosilicate glass 4 is placed in the female mold 1, and press-fitted by applying pressure from above with a male mold. This male mold 2 is slightly smaller than the concave portion of the female mold 1, and forms the mold 6' of the reflecting mirror in the gap produced during pressing. The male die 2 is pushed down almost instantaneously, and the male die 2 is then raised. Then, the mold 6' of the reflecting mirror is taken out from the female mold 1 quickly after the male mold 2 is raised through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com