Grinding device and method for determining thickness of grinded material

A grinding device and grinding shaft technology, which is applied to the parts of grinding machine tools, grinding machines, optical surface grinders, etc., can solve the problem of high thickness accuracy of the ground material, high technical ability requirements of the staff, and difficulty in improving the ground material Thickness detection accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

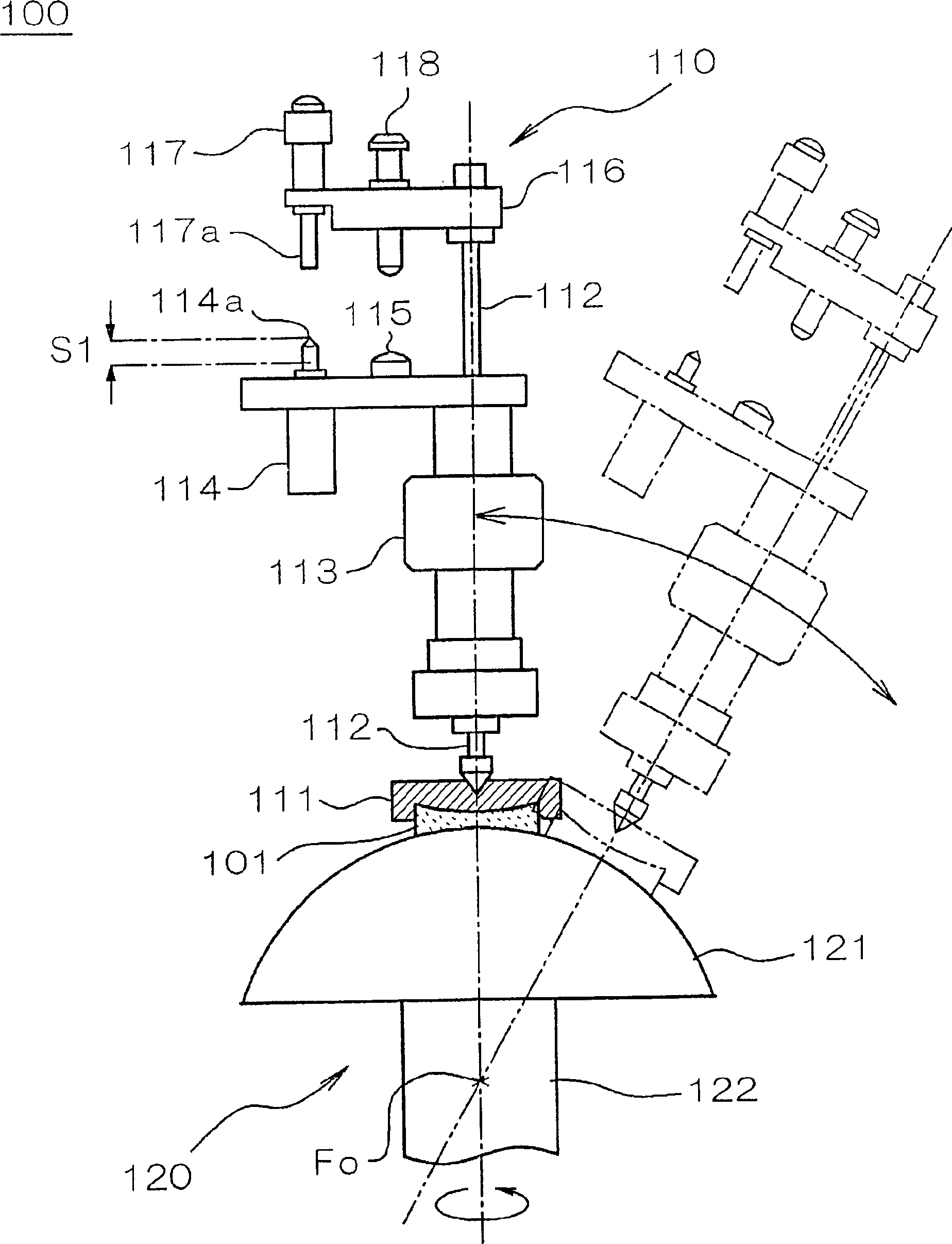

[0027] Embodiments of the present invention will be described below with reference to the drawings.figure 1 It is a schematic structural diagram showing the main part structure of the polishing apparatus 100 of this embodiment. The grinding device 100 shown in the figure is an upper shaft ball core swinging type grinding device. However, the function and structure of the upper shaft part and the lower shaft part of the grinding device 100 may be reversed to form a lower shaft center swing type grinding device. In this polishing device 100, the upper shaft part 110 rotates around the swing center Fo, and the lower shaft part 120 rotates around the axis.

[0028] On the upper shaft portion 110 , a first grinding member (grinding disc) 111 is fixed to a first grinding shaft (swing member) 112 , and the first grinding shaft 112 is axially supported relative to a supporting member 113 so as to be movable in the axial direction. The support member 113 is driven by a swing drive mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com