Damaged pipeline repairing apparatus and method thereof

A pipeline repair and pipeline technology, which is applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve complex and difficult problems such as loose connections of PE and PP pipes, and affect the effect of long-term use. The effect of cost reduction, low dryness and cleanability, and convenient and quick repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

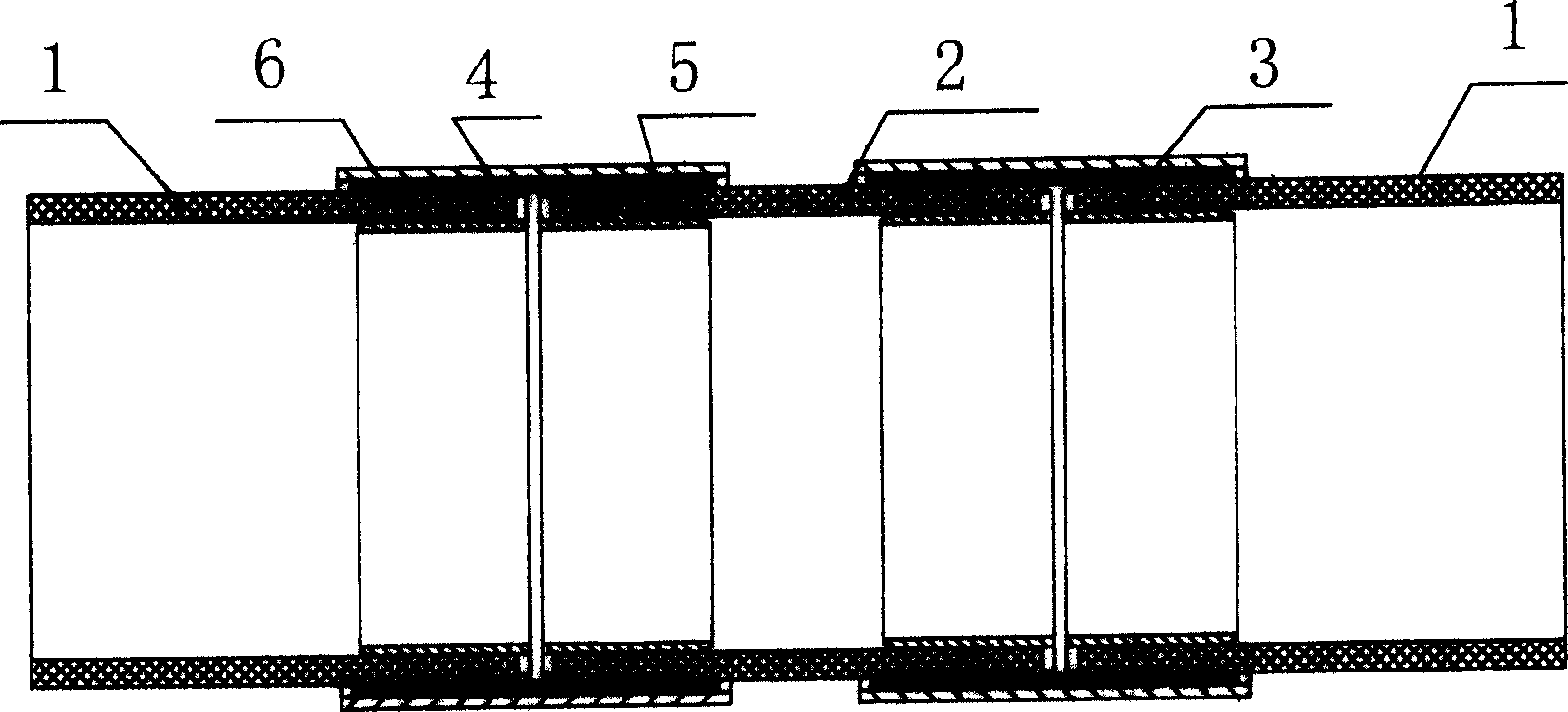

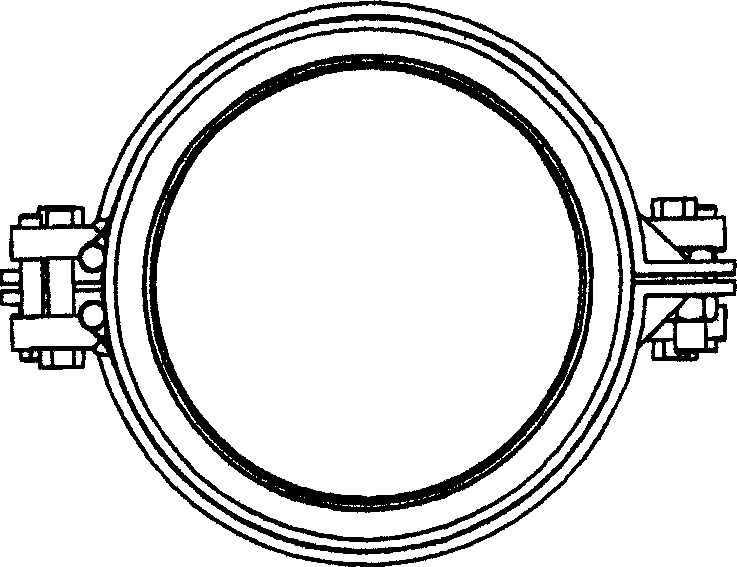

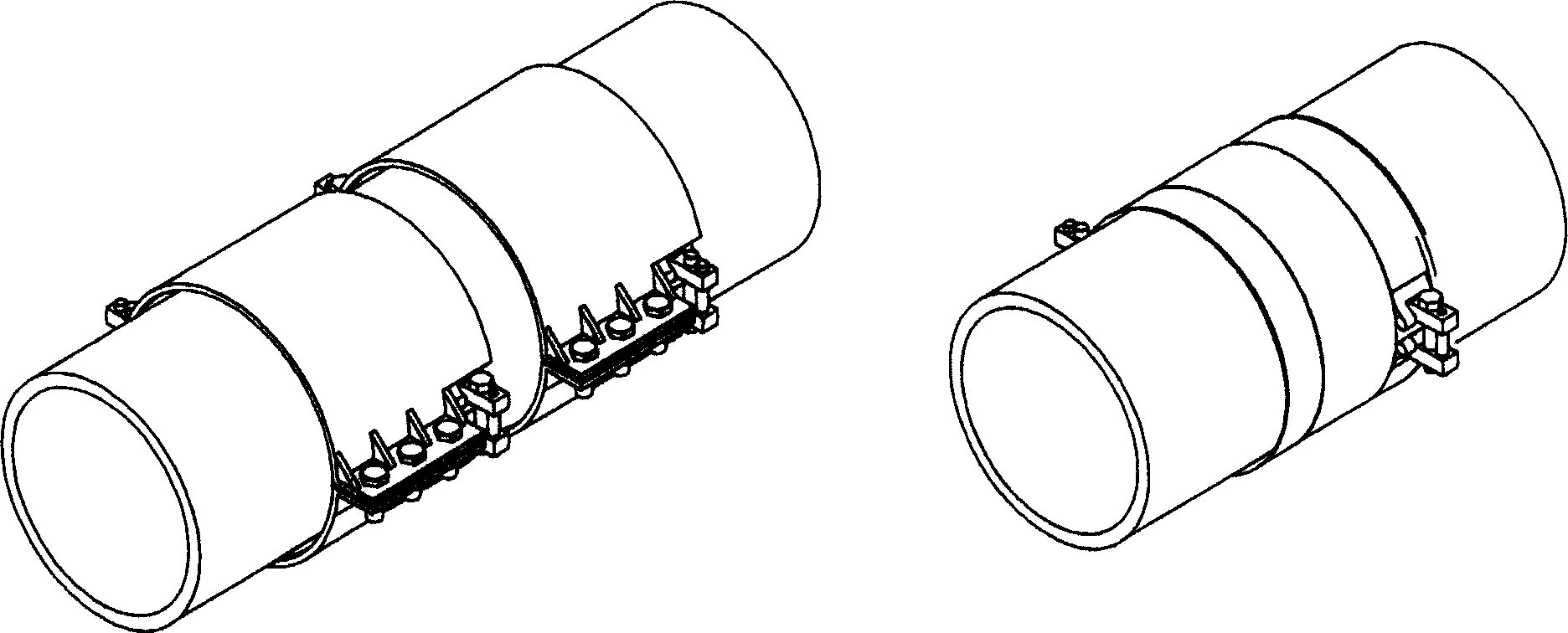

[0043] The structural sectional view of this embodiment is as attached figure 1 As shown, it is composed of a broken pipe 1, a replacement pipe 2, a steel hoop 3, a rubber sleeve 4, a stainless steel strap 5, and a half plate 6.

[0044] The pipeline repair method is as follows:

[0045] The part to be repaired of the ruptured pipeline 1 is cut into two sections;

[0046] Put the steel hoop 3 into the ports of the ruptured pipe 1 and the replacement pipe 2 respectively;

[0047] Align the ports of the ruptured pipe 1 and the replacement pipe 2, and put a rubber sleeve 4 on the joint of the two pipes;

[0048] Lock both ends of the rubber sleeve 4 with a stainless steel pull belt 5 to form a sealed cavity;

[0049] On the outer surface of the rubber sleeve 4, two upper and lower half boards 6 are put on, and the joints of the half boards 6 are locked with screws.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com