Method of producing coating composition and coating composition made therefrom

A composition and coating technology, applied in the direction of powder coating, coating, coating non-metallic protective layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

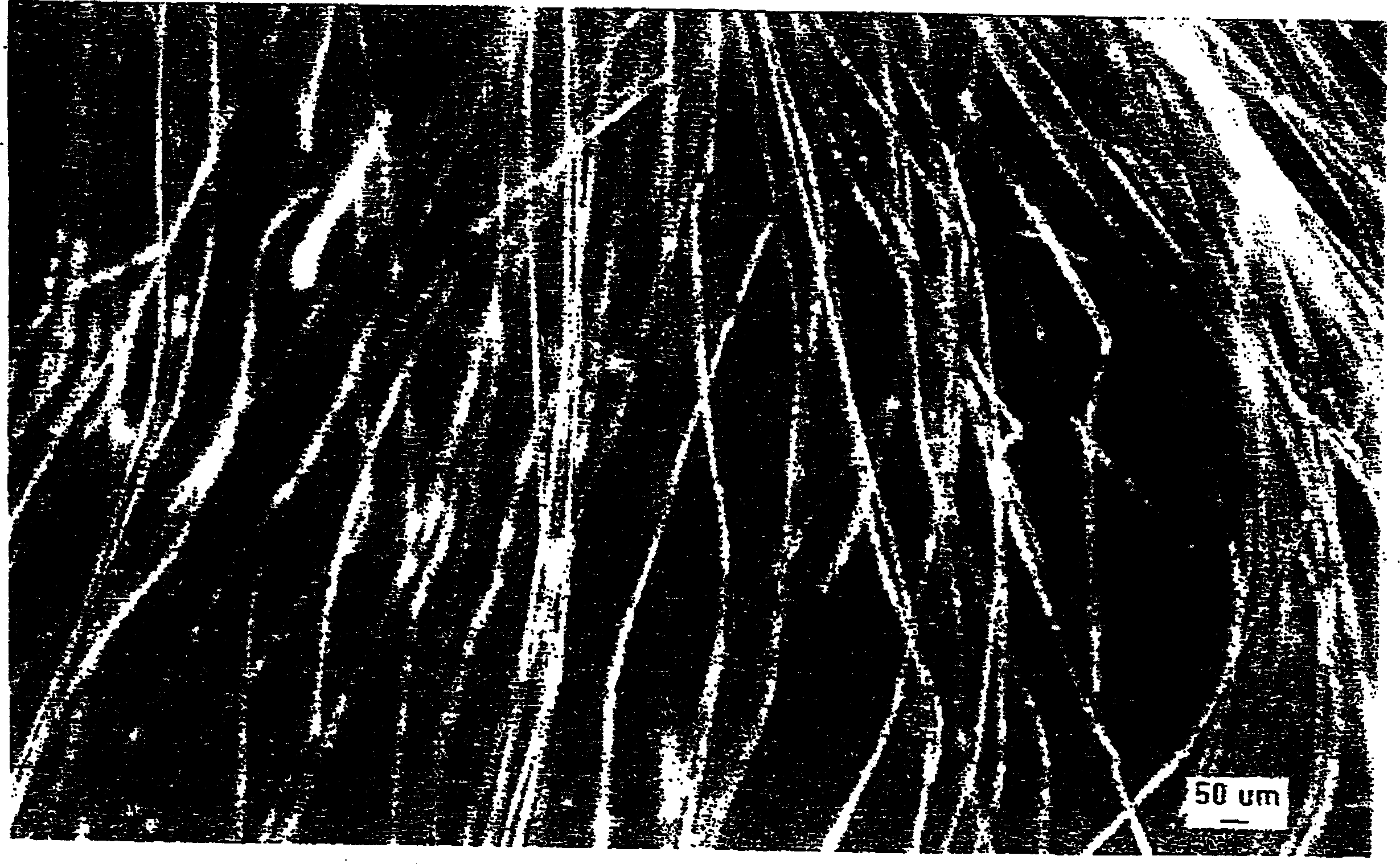

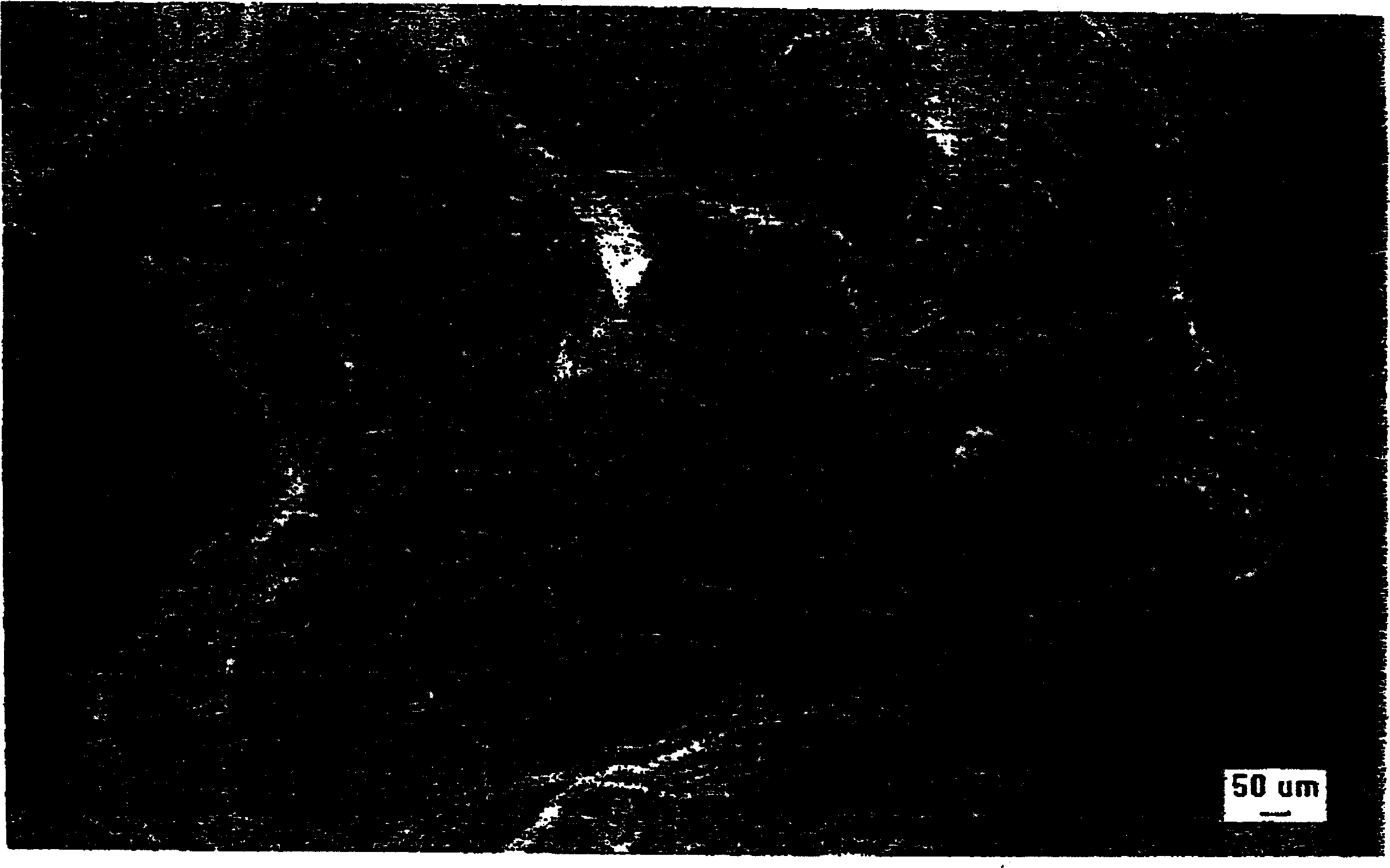

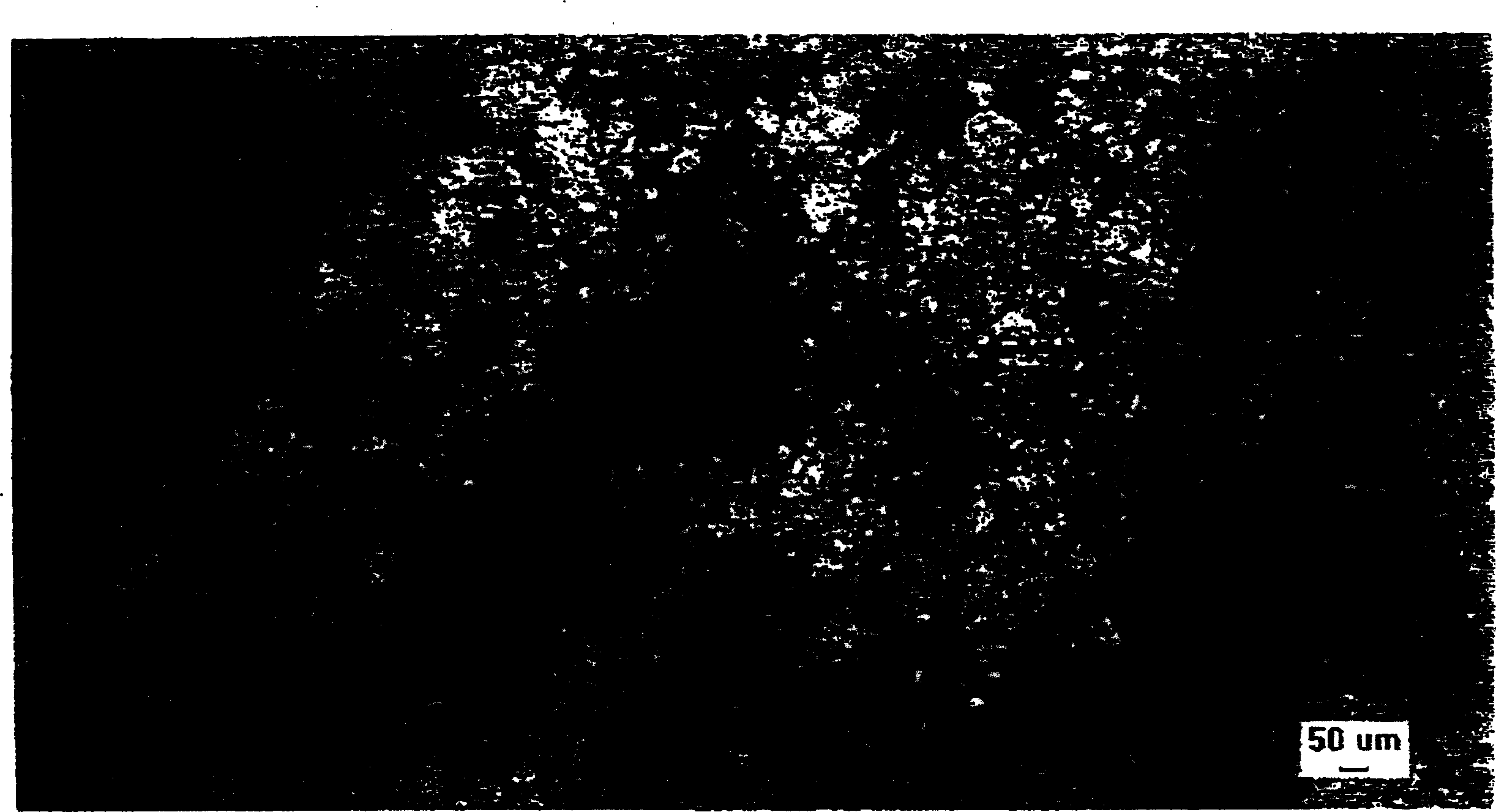

Image

Examples

Embodiment 1

[0165] Embodiment 1 (contrast)

[0166] The primer was prepared by mixing together 600 grams of 615S Variprime(R) self-corrosion primer with 400 grams of 616S Converter, both supplied by DuPont Company, Wilmington, Delaware.

Embodiment 2

[0168] Example 1 was mixed with 17.50 grams of Slurry 3 to produce Example 2.

Embodiment 3

[0169] Embodiment 3 (contrast)

[0170] A two-pack primer was prepared by mixing together 954.40 grams of 4004S Ultra Productive 2K Primer-Filler (gray), 85.31 grams of 1085S ChromaSystem® Mid-Temp Reducer, and 143.40 grams of 4075S Ultra Productive Mid Temp Activator. All courtesy of DuPont Company, Wilmington, Delaware.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com