Rotary machine with rotary sensor

A technology of rotating machines, rotating detectors, applied in the direction of instruments, devices using electrical/magnetic methods, control/regulatory systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

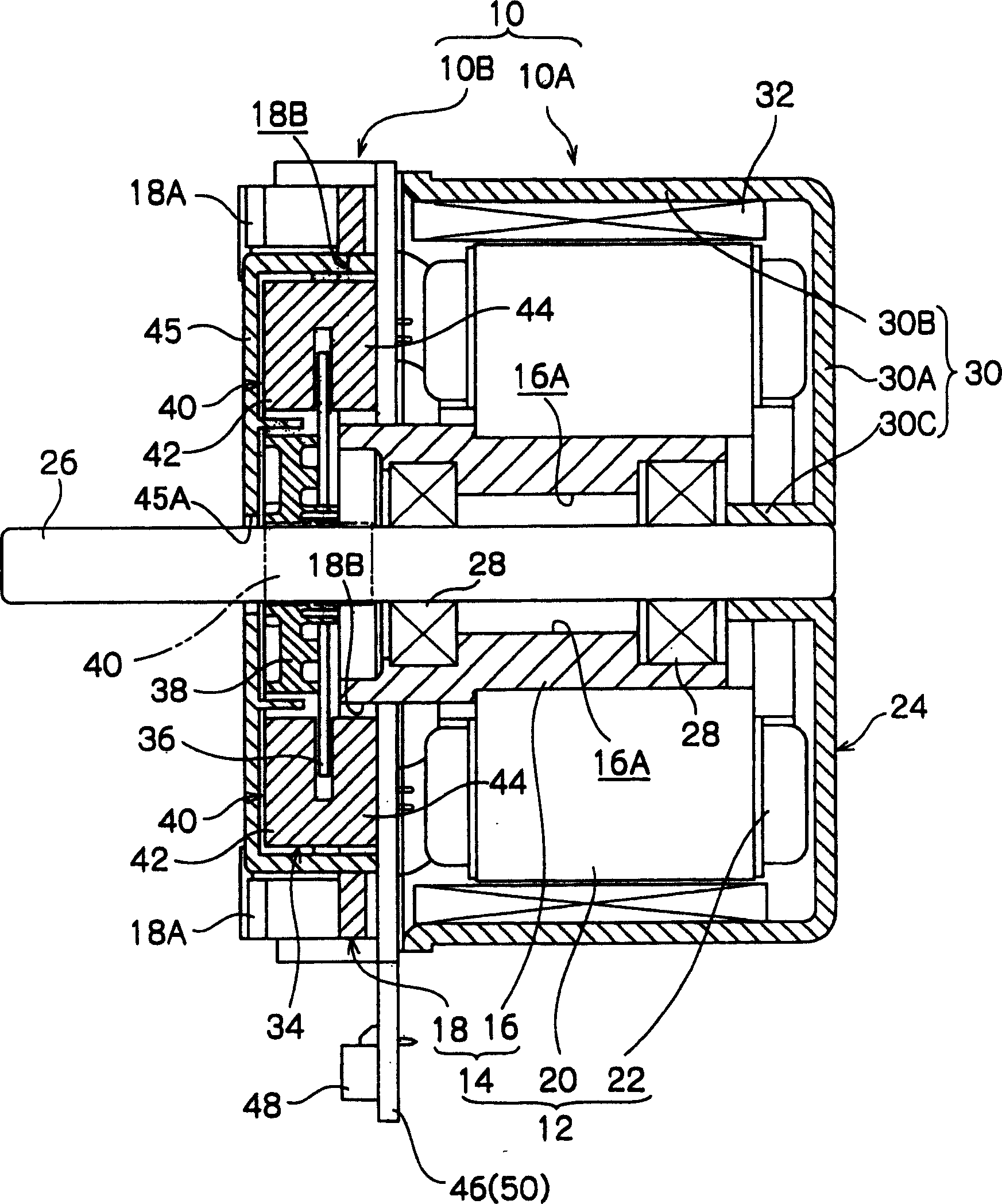

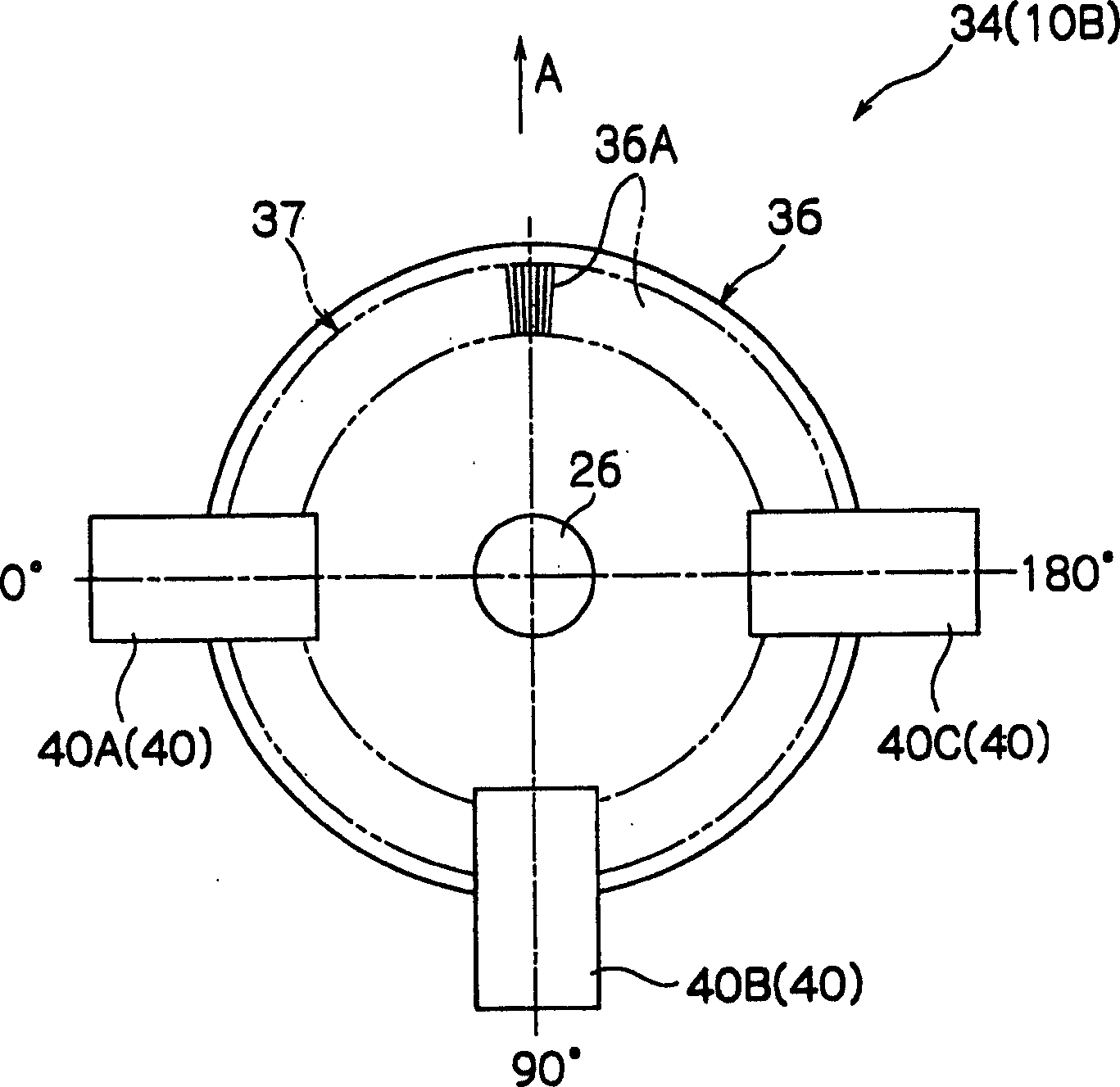

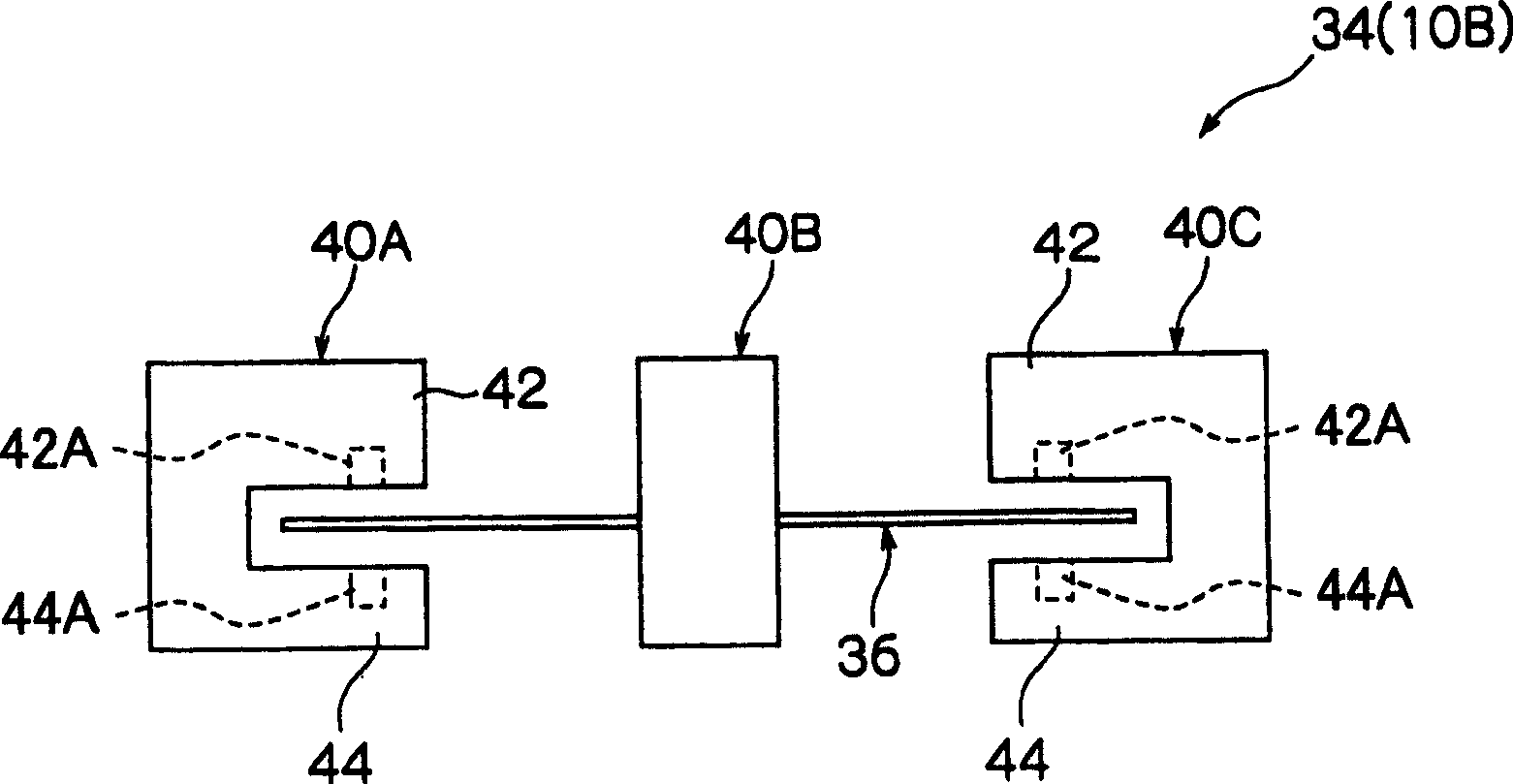

[0029] according to figure 1 Referring to FIG. 8 , an electric motor (rotary machine) according to an embodiment of the present invention, that is, an outer rotor type motor 10 will be described. First, the overall schematic configuration of the motor unit 10A of the outer rotor type motor 10 will be described, and then the rotation control unit 10B as the rotation control device, which is the main part of the present invention, will be described.

[0030] exist figure 1 In , a side section of the outer rotor type motor 10 is shown. As shown in the figure, the outer rotor type motor 10 is composed of a motor unit 10A and a rotation control unit 10B which will be described later. The motor unit 10A includes a stator 12 , and the stator 12 includes a stator base 14 . The stator base 14 is composed of a substantially cylindrical central tube portion 16 and a flat plate-shaped stator cover 18 protruding from an outer peripheral portion of one end portion of the central tube p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com