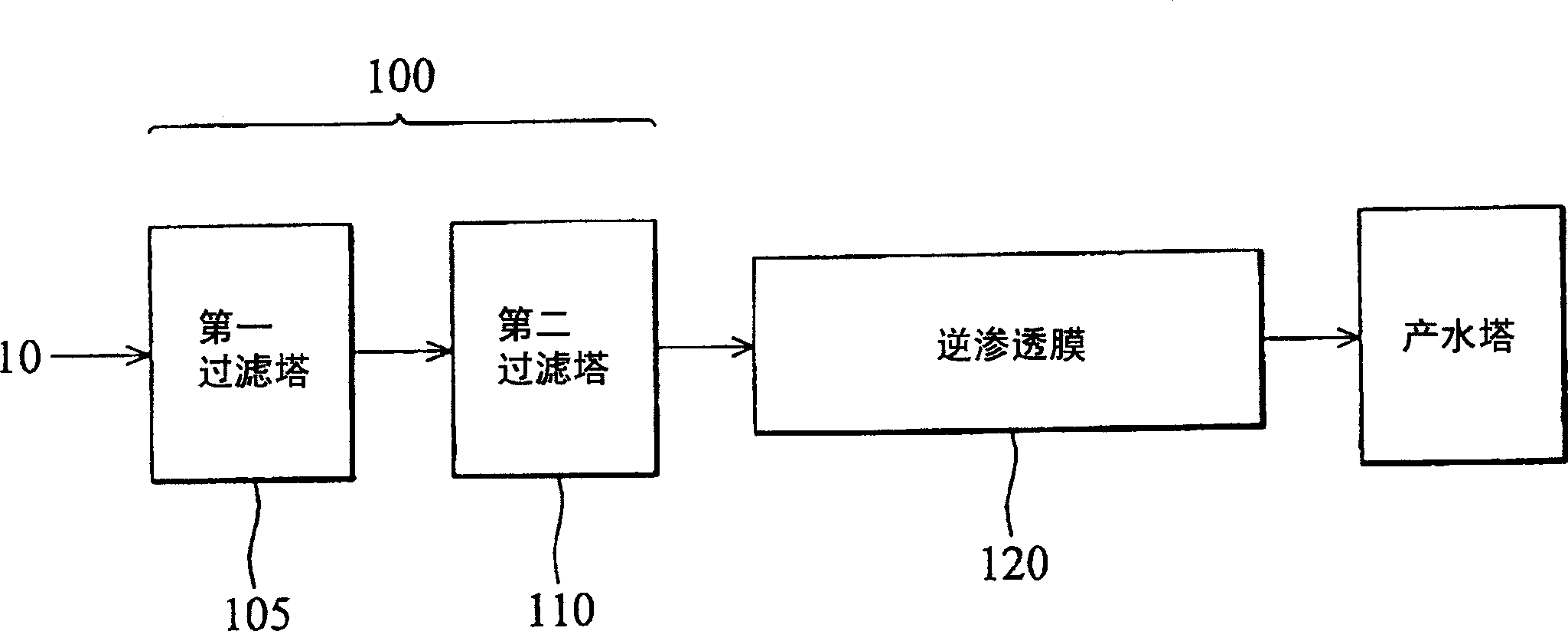

Method of cleaning reverse osmosis membrane and discharge water recovery method using said method

A technology of reverse osmosis membrane and waste water recovery, which is applied in the direction of osmosis/dialysis water/sewage treatment, separation methods, chemical instruments and methods, etc., and can solve the problems of low cost and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

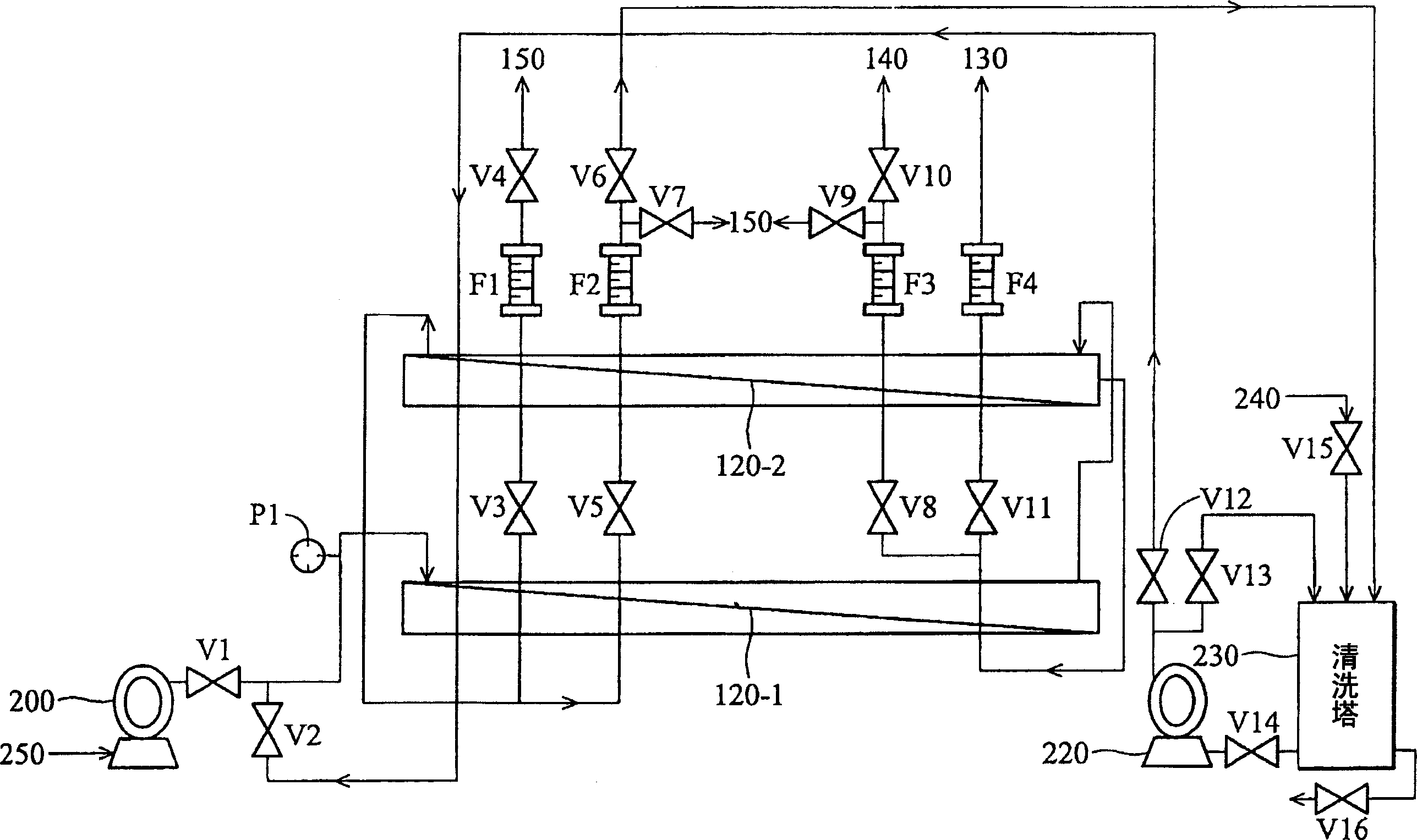

[0035] see figure 2 , is a method for cleaning a reverse osmosis membrane according to an embodiment of the present invention. In this method, before cleaning the reverse osmosis membrane 120, a cleaning agent preparation will be carried out. The steps are as follows. First, start a high-pressure pump 200, and open the valve 1, so that the filtrate 250 flows through the pressure gauge P1 and enters the reverse osmosis membrane. Permeable membrane 120-1.

[0036] If the water quality of the filtrate discharged from the reverse osmosis membrane 120-1 at this time meets the standard of process water, it will directly pass through the valve 11 through the flow meter F4 and enter the water production tower 130 for storage for use in the process, or by the branch pipeline ( Through the valve 8, through the flow meter F3 and the valve 10), it enters the temporary storage tower 140 for storage. During this period, the valve 9 can also be opened to introduce the wastewater into a neu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap