Semiconductor laser ageing method

A semiconductor and laser technology, applied in the field of semiconductor laser aging detection methods and the equipment used, can solve the problems of aging, LD overcurrent aging, affecting life and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

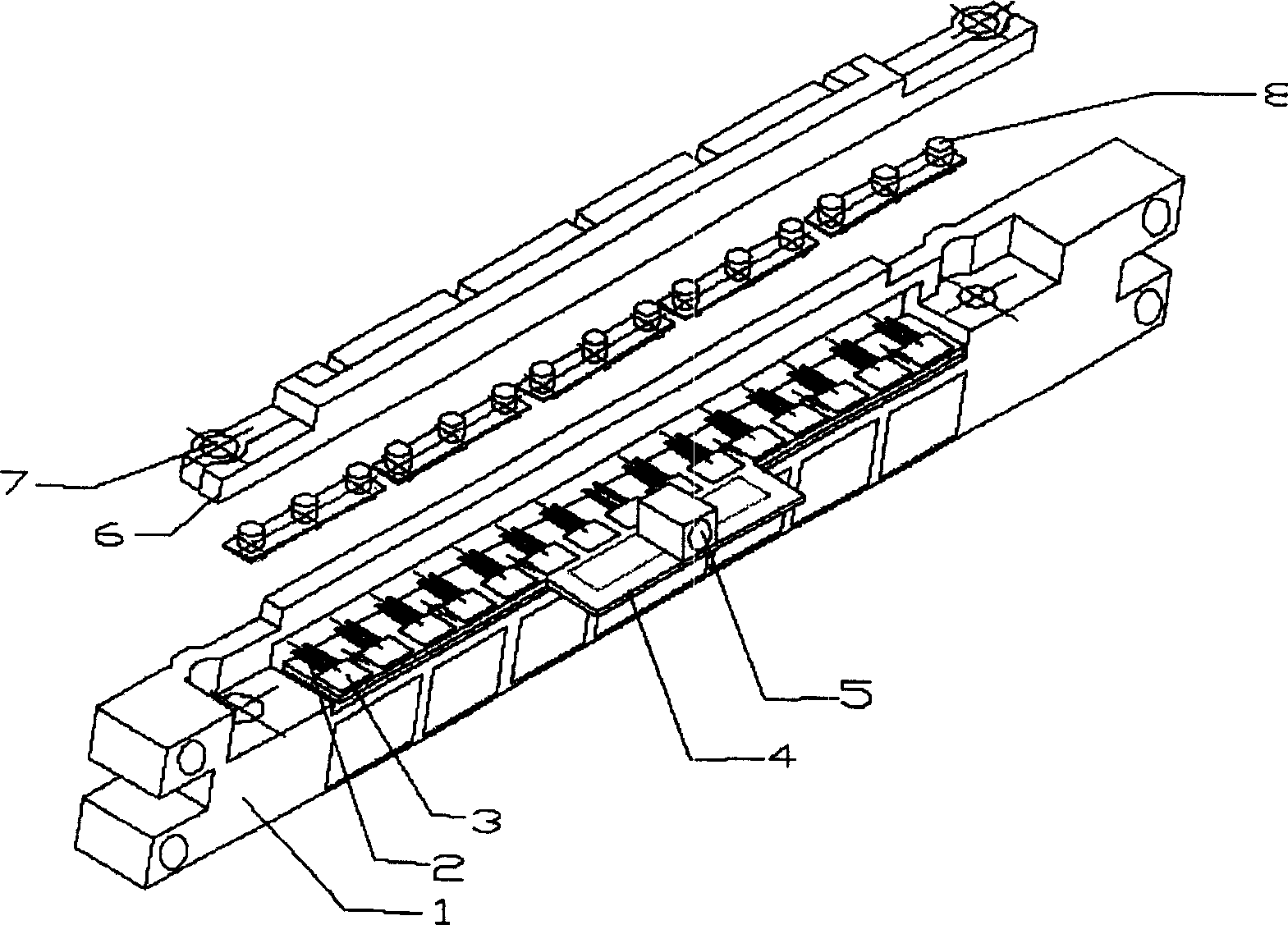

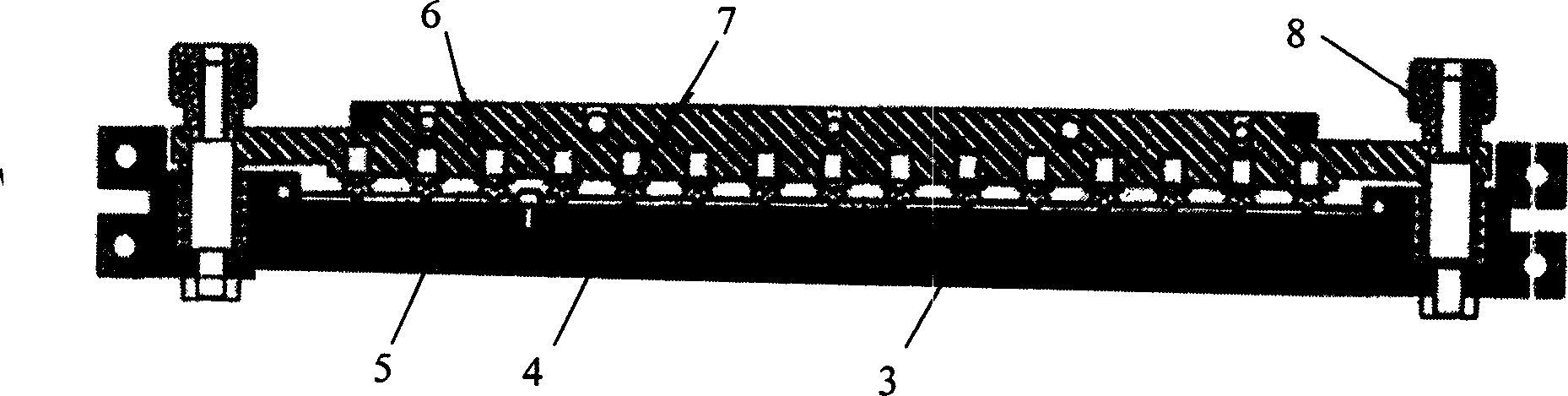

Image

Examples

Embodiment Construction

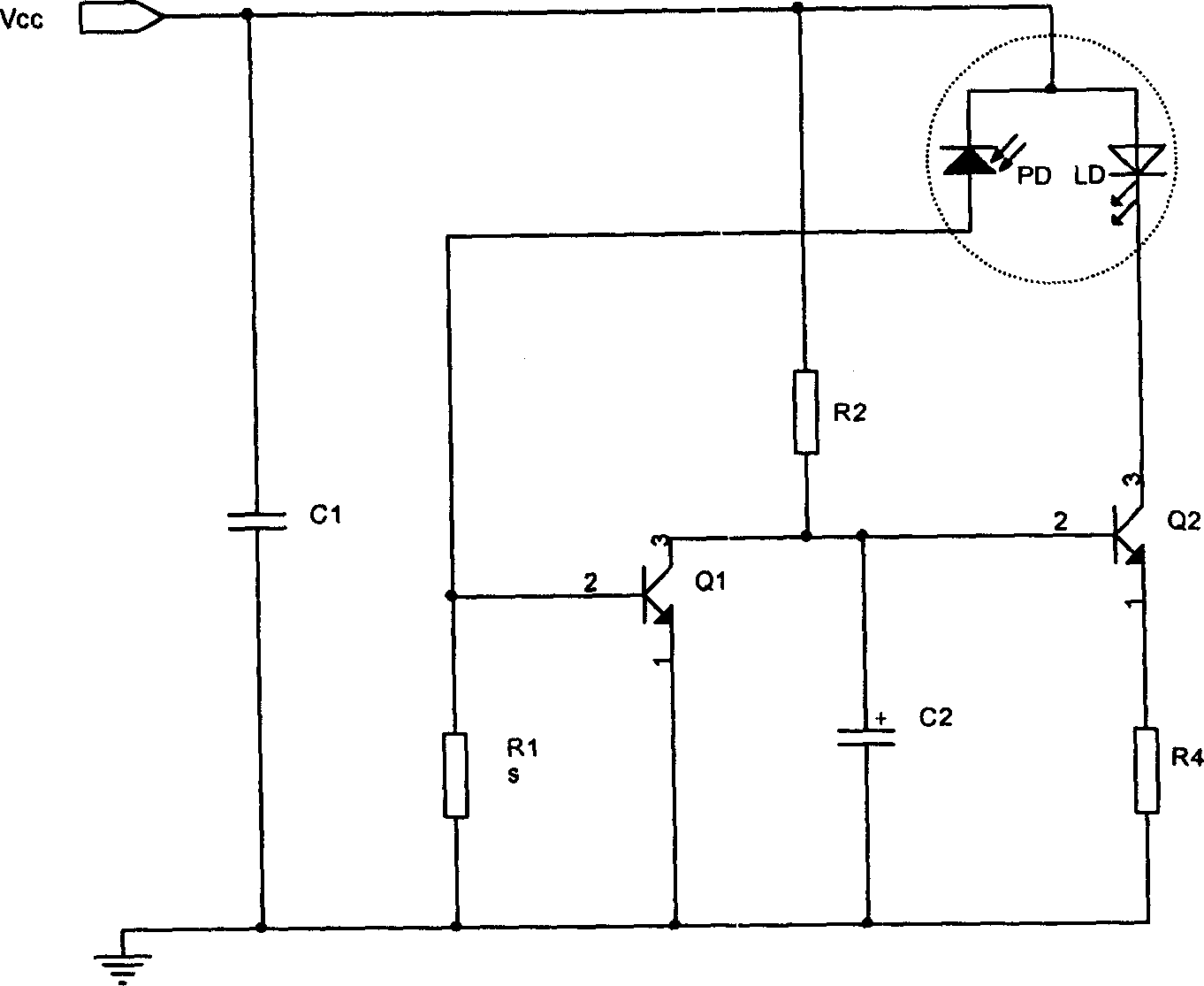

[0009] The idea of the present invention is: in the application of the semiconductor laser LD, it is always required that the LD can work at a constant power, so a constant power control circuit must be provided. Before LD is applied to actual products, in order to ensure the life of LD application products and the quality of LD in the application process, it is always hoped that LD can be aged in a constant power control circuit similar to its application, and it is more hoped that the aging power The working power is the same as the actual application or the aging power is higher than the actual application. At the same time, in order to be closer to the actual working conditions of the LD and to protect the LD, no adjustment can be made during the aging process (it will not always be adjusted in the actual application of the LD).

[0010] In order to meet the above requirements, people can of course directly use the constant power control circuit or a circuit close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com