Shaft damper

A technology for dampers and damping shafts, applied in the direction of shafts, flexible shafts, shock absorbers, etc., can solve problems such as no effect of bending vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

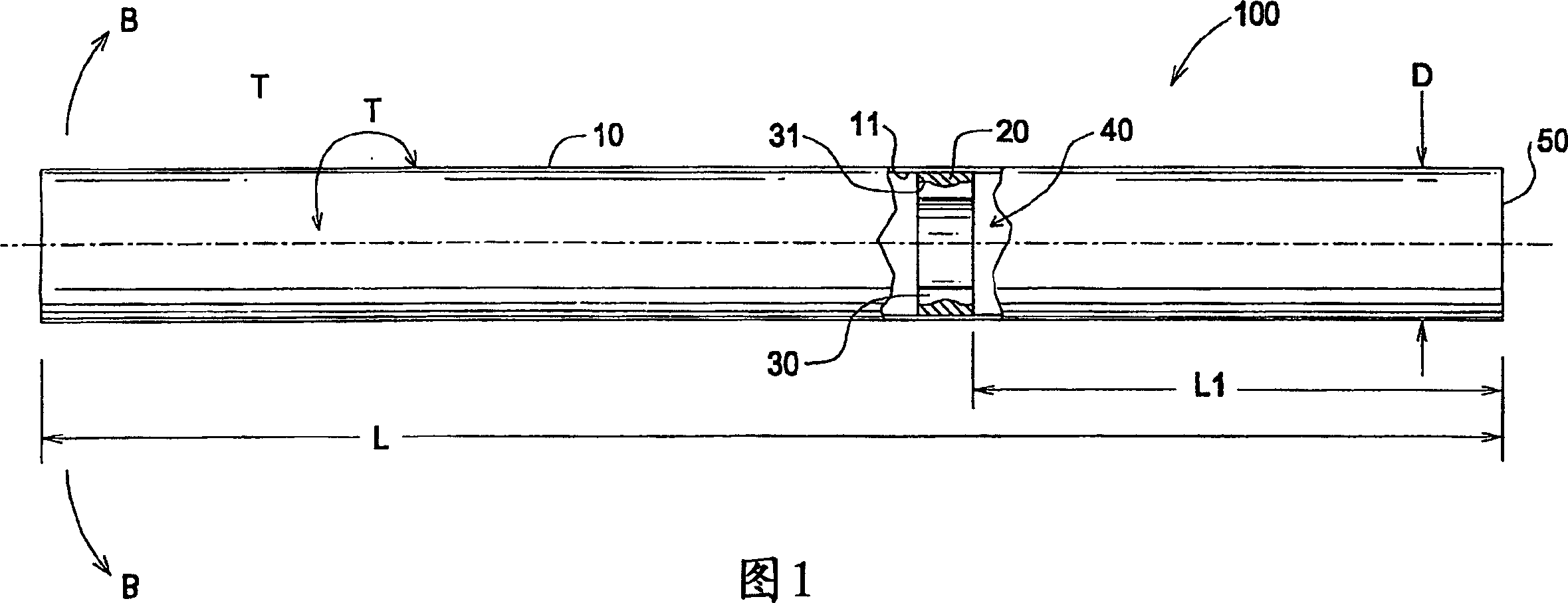

[0015] Figure 1 is a cross-sectional side view of the shaft damper of the present invention. The shaft damper 100 includes a shaft body 10 and a hole 40 . The shaft 10 has a length L and a diameter D. The elastic member 20 is engaged between the shaft body 10 and the inertia member 30 in the hole 40 . The elastic member 20 and the inertial member 30 are located at a distance L1 from the end 50 of the shaft 10 .

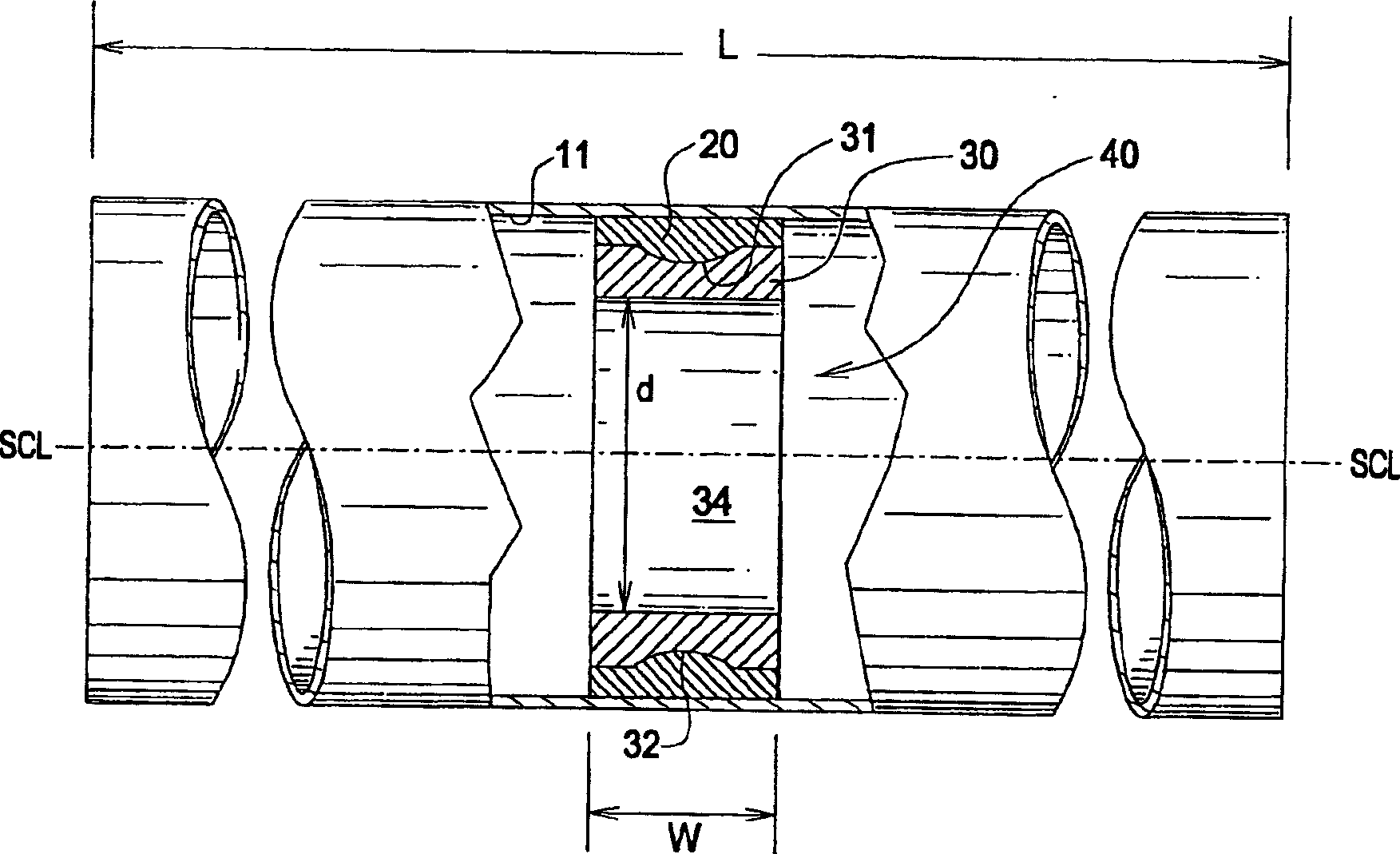

[0016] figure 2 is a detailed view of the shaft damper of the present invention. The elastic member 20 is engaged between the inner surface 11 of the shaft and the outer surface 31 of the inertia member. The inner surface 11 may have a surface roughening to increase the surface coefficient of friction.

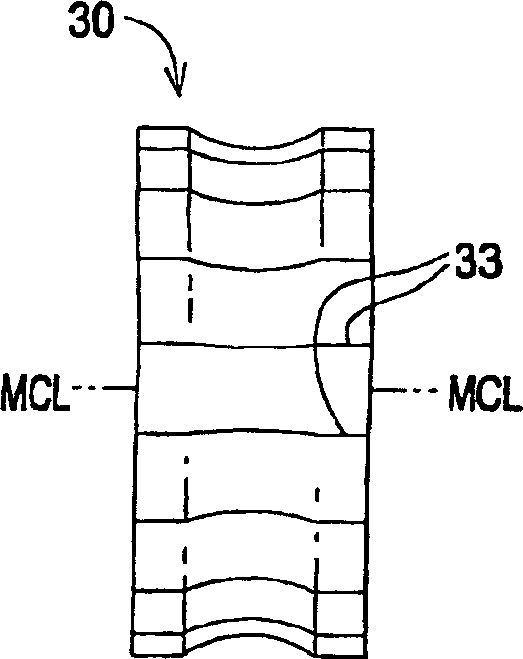

[0017] The elastic member 20 is compressed between the inner surface 11 and the outer surface 31 in the range of 5% to 50%. The inertial member 30 further includes an undulating surface 32 on the outer surface 31 for mechanically engaging the inertial member 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com