Record autochanger for high-energy radiation X ray photograph

A high-energy ray and light photography technology, applied in optics, instruments for radiological diagnosis, medical science, etc., can solve the problems of greater harm to human health, low efficiency of photographic inspection, etc., to reduce auxiliary preparation time, reduce the number of times and Duration of stay, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

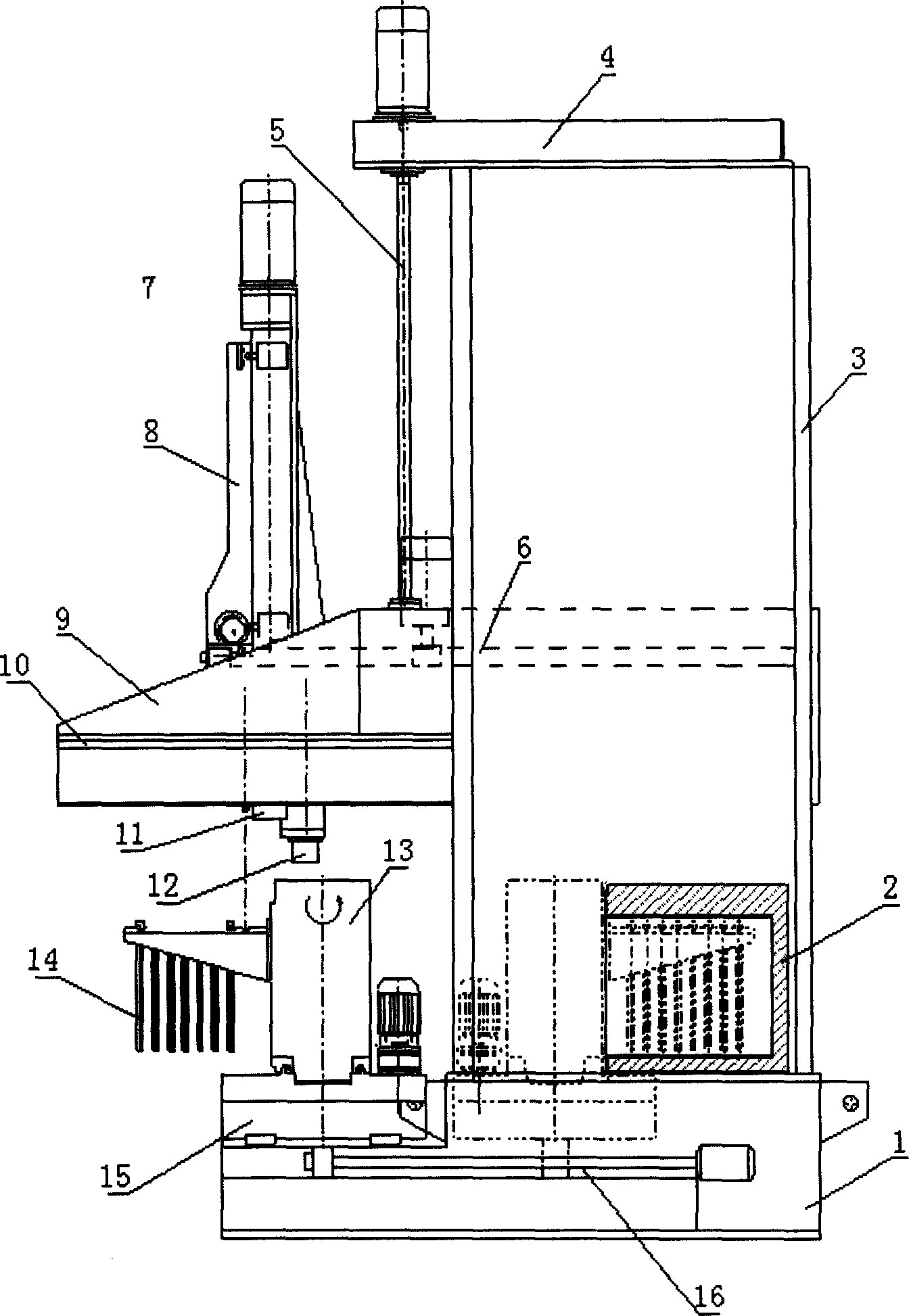

[0014] Referring to the accompanying drawings, the present invention includes a frame 3 , a bracket 9 and a base 1 connected to the frame 3 . The base 1 is provided with a film box capable of airtightly storing films, which is composed of a housing 2 connected to the upper plane of the base 1 and a movable film holder 13 that can be airtightly buckled with the housing 2 . A plurality of sheets of film 14 can be placed vertically evenly on the moving film holder 13, and the bottom of the moving film holder 13 is connected with a rotary mechanism 15 that can make it rotate. The slewing mechanism 15 is a rotating width structure formed by an external gear and an internal ring gear driven by a motor. The bottom of the slewing mechanism 15 is connected with the push-pull mechanism one 16 which is horizontally fixed in the base 1 . Push-pull mechanism one 16 is made up of motor and spiral width, and motor and the screw mandrel that is connected with motor output shaft are fixed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com