Pressure-compensated drip irrigation belt

A technology of pressure compensation and drip irrigation belt, which is applied in the direction of climate change adaptation, horticulture, botany equipment and methods, etc., can solve the problems that affect the service life of irrigation equipment, cannot use underground irrigation, and blockage can not be controlled, so as to prevent internal blockage, Ease of transportation and high water-saving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

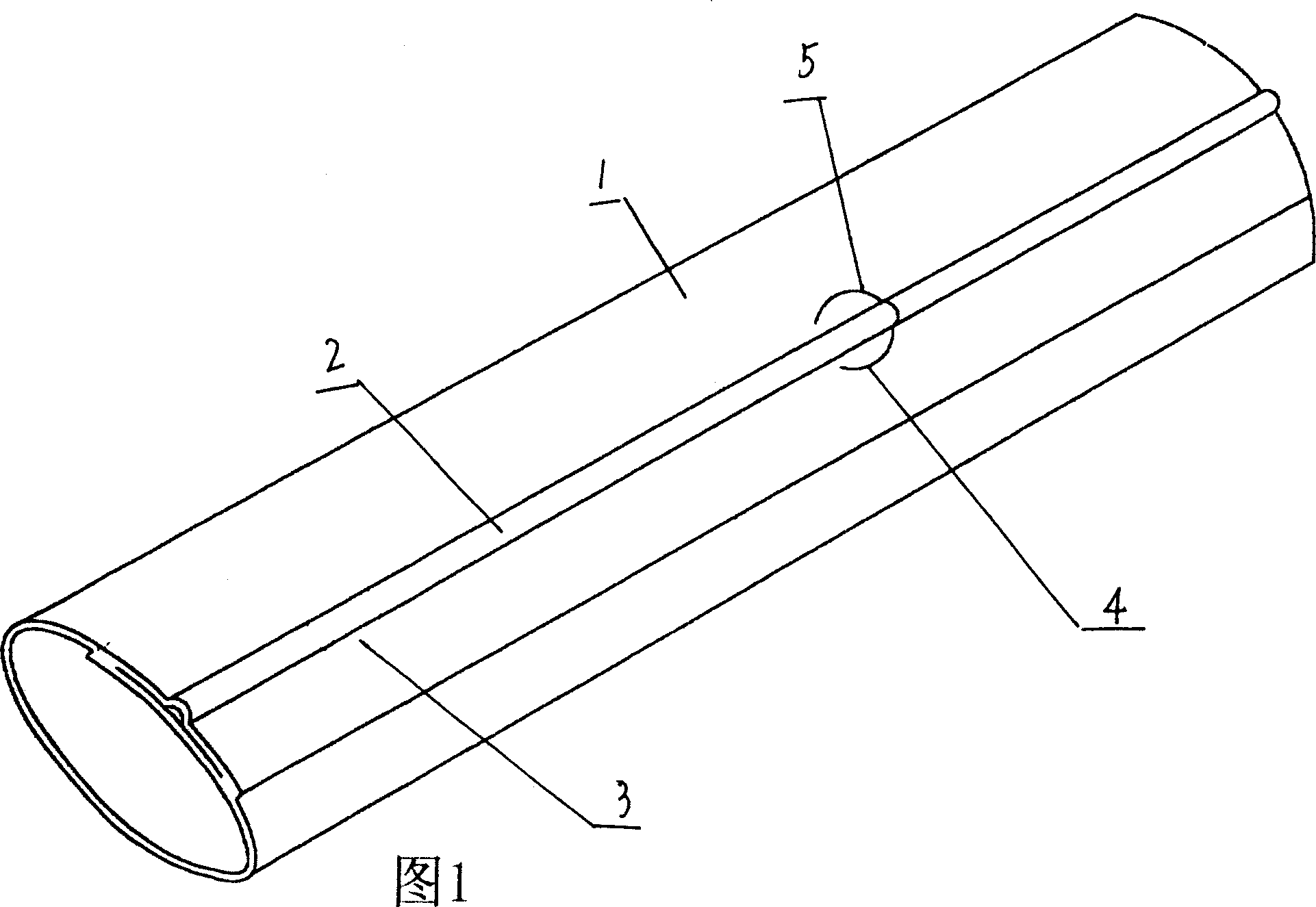

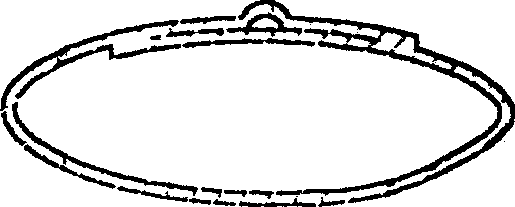

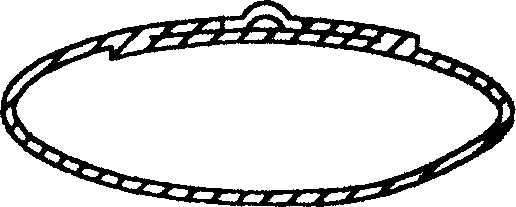

[0019] A pressure-compensated drip irrigation belt, the drip irrigation belt is a double-layer structure closed on both sides in the area where the flow channel and the water inlet and outlet are set, and the flow channel is pre-formed before welding the double-layer pipe wall. As shown in Figure 1, the hook groove flow channel of the drip irrigation tape is set on the outer layer; as shown in Figure 5, the hook groove flow channel of the drip irrigation tape is set on the inner layer. Both forms have an arc-shaped hook groove-shaped flow channel 2 running through the belt body in the belt body 1. This flow channel deforms under the change of water pressure in the pipe, and this deformation affects the cross-sectional area of the flow channel. The water output at different pressures can be automatically adjusted to achieve uniform irrigation. Several water inlets 3 and water outlets 4 are arranged staggeredly on the belt body, so that each water outlet on the drip irrigation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com