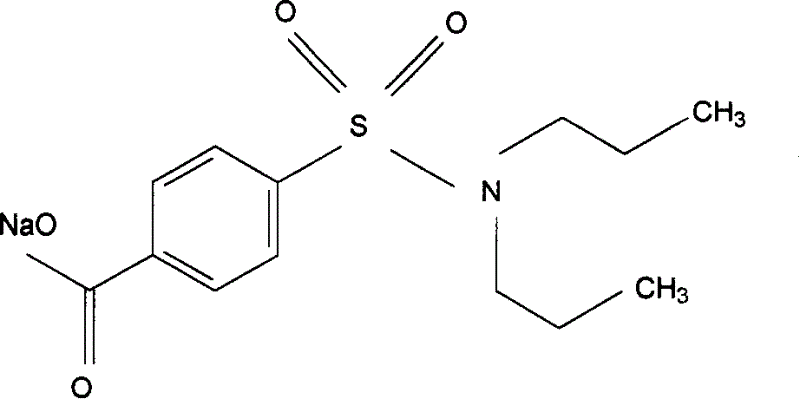

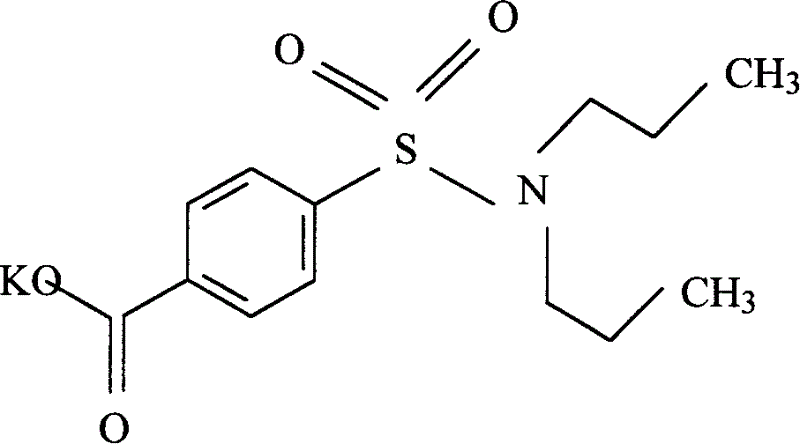

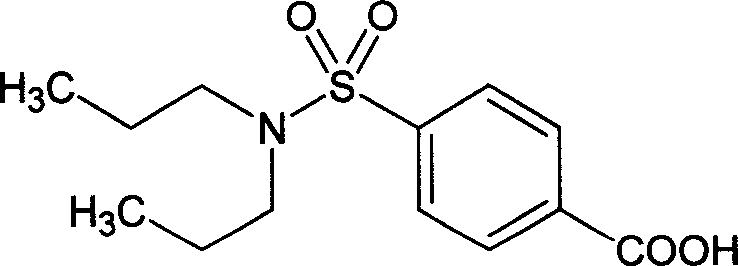

Preparation of sodium probenecid and potassium probenecid, compound injection prepared by sodium probenecid, potassium probenecid and beta-lactam antibiotics, and use thereof

A technology of probenecid sodium and probenecid potassium, which is applied in the field of powder injection and freeze-dried powder injection, can solve the problem of probenecid sodium that has not yet been seen, and achieve the effect of eliminating hemolysis and prolonging the half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0347] Example 1: Dissolve 22 kilograms of sodium hydroxide in 200 liters of purified water, add 142 kilograms of probenecid after all the dissolution, heat to 60° C., adjust the pH to above 7.5, and keep stirring until the pH value is basically constant. Under the condition of 60°C, it is sterilized by filtration through a 0.45 μm filter membrane, and then finely filtered through a 0.22 μm filter membrane to remove pyrogens, and dried under sterile conditions to obtain the raw material of probenecid sodium that meets the standards for human drug injections. White or off-white crystalline powder.

[0348] Probenecid sodium and penicillin G sodium are mixed under aseptic conditions at a weight ratio of 1:3, subpackaged under aseptic conditions, and finally made into a powder injection.

Embodiment 2

[0349] Example 2: Dissolve 28 kg of sodium hydroxide in 280 liters of purified water, add 143 kg of probenecid after all the dissolution, heat to 65°C, adjust the pH to above 8, and keep stirring until the pH value is basically constant. Under the condition of 65°C, it is sterilized by filtration through a 0.45 μm filter membrane, and then finely filtered through a 0.22 μm filter membrane to remove pyrogens, and dried under sterile conditions to obtain the raw material of probenecid sodium that meets the standards for human drug injections. White or off-white crystalline powder.

[0350] Probenecid sodium and ampicillin sodium are mixed under aseptic conditions at a weight ratio of 1:2.8, subpackaged under aseptic conditions, and finally made into a powder injection.

Embodiment 3

[0351] Example 3: Dissolve 40 kg of sodium hydroxide in 300 liters of purified water, add 150 kg of probenecid after all dissolved, heat to 70°C, adjust pH to 10, and keep stirring until the pH value is basically constant. Under the condition of 70°C, it is sterilized by filtration through a 0.45 μm filter membrane, then finely filtered through a 0.22 μm filter membrane to remove pyrogens, and dried under sterile conditions to obtain the raw material of probenecid sodium that meets the standards for human drug injections. White or off-white crystalline powder.

[0352] Probenecid sodium and cefazolin sodium are mixed under aseptic conditions at a weight ratio of 1:2, subpackaged under aseptic conditions, and finally made into a powder injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com