Transmission arrangement for transfer teeth of cylinder type sewing machine

A transmission structure, sewing machine technology, applied in sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of limited transmission device structure, inability to miniaturize the cylinder part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Refer to the following Figure 1 to Figure 5 Preferred embodiments of the present invention will be described.

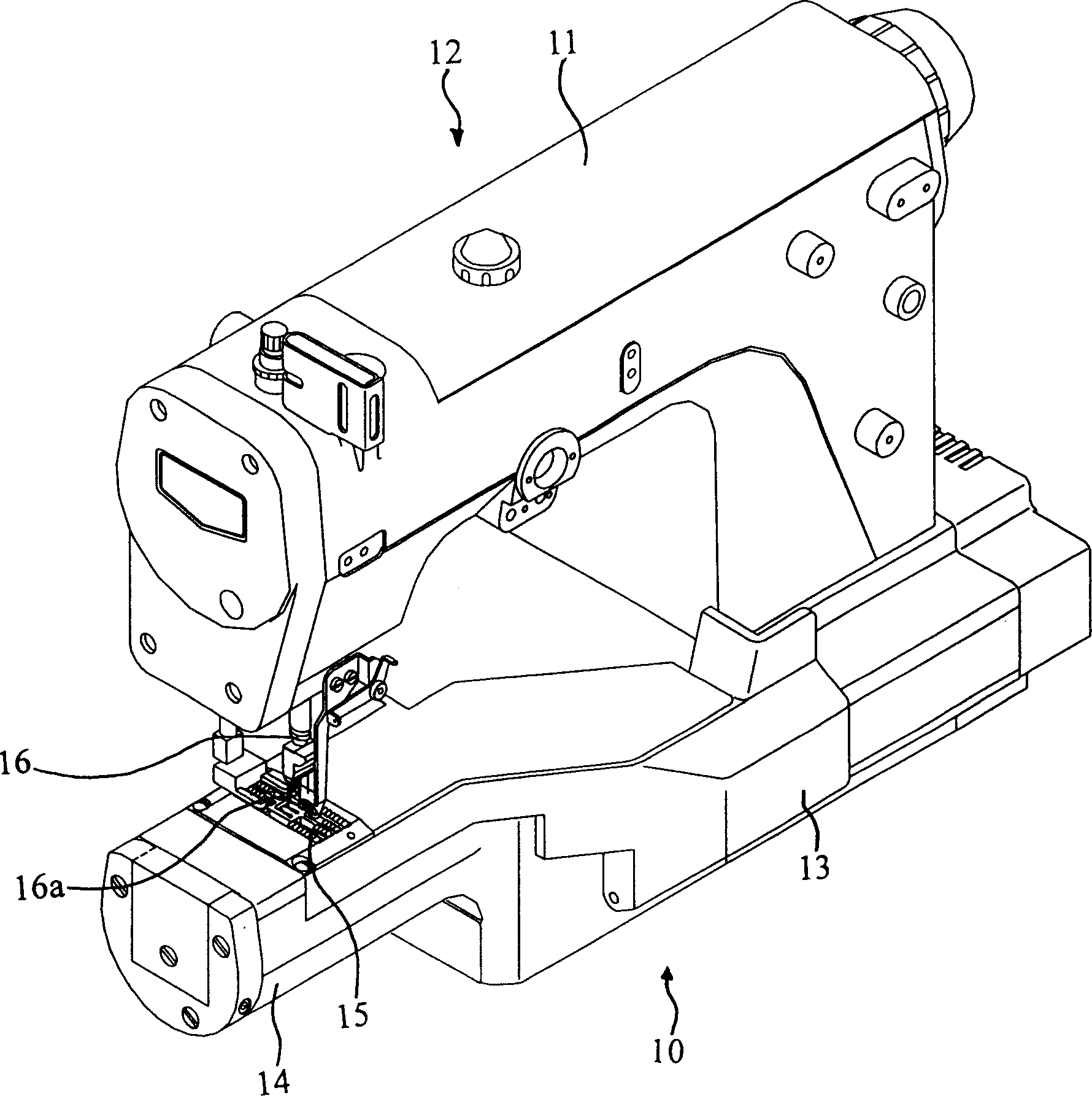

[0014] Such as figure 1 As shown, the sewing machine body 12 of the present invention is composed of a table part 10 and an arm part 11 located at the right end of the table part facing upwards. The machine unit 10 is composed of a rectangular box-shaped main unit 13 and a tubular cylindrical unit 14 protruding laterally from the main unit 13 . A needle plate 15 is provided on the cylindrical unit 14 .

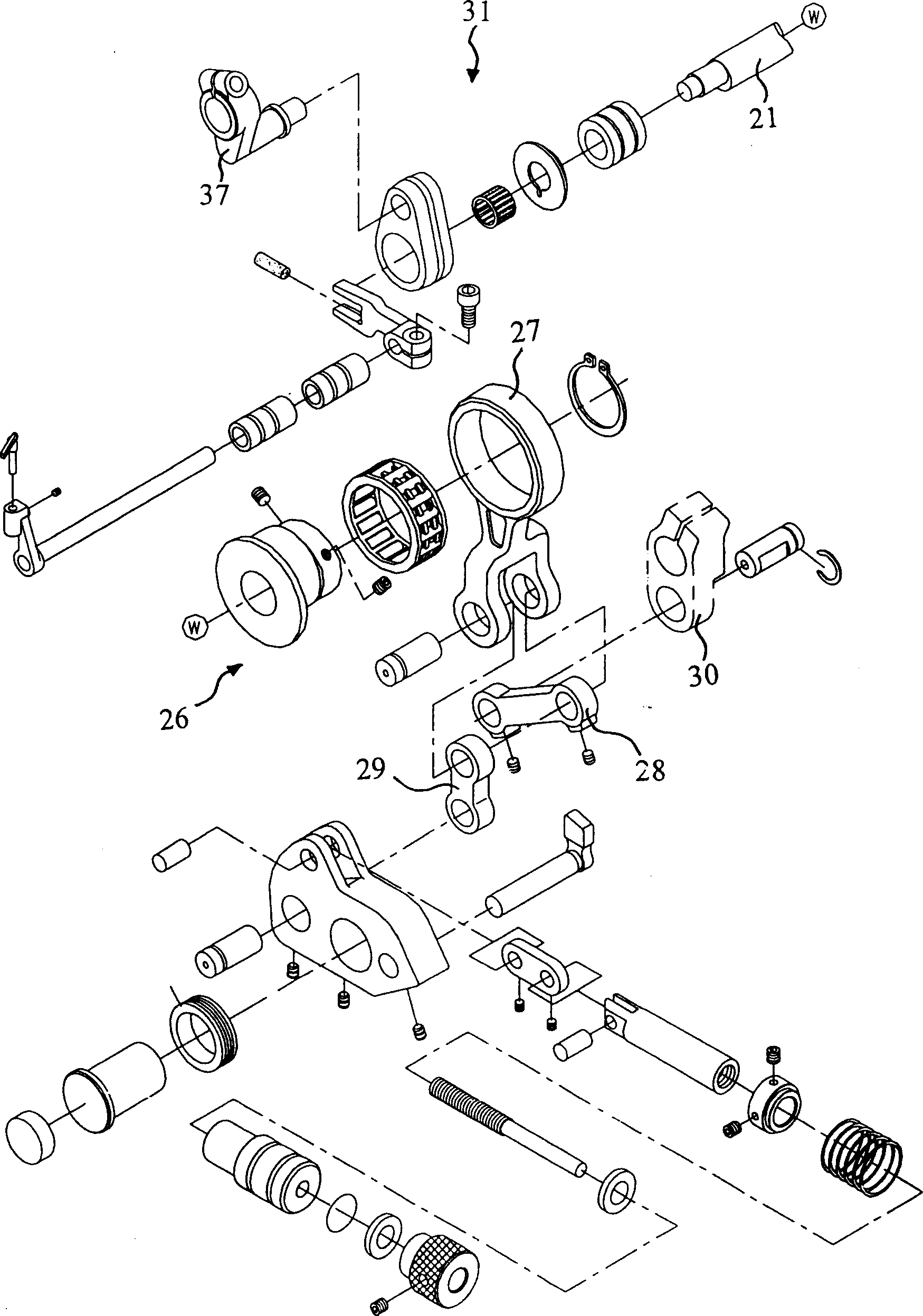

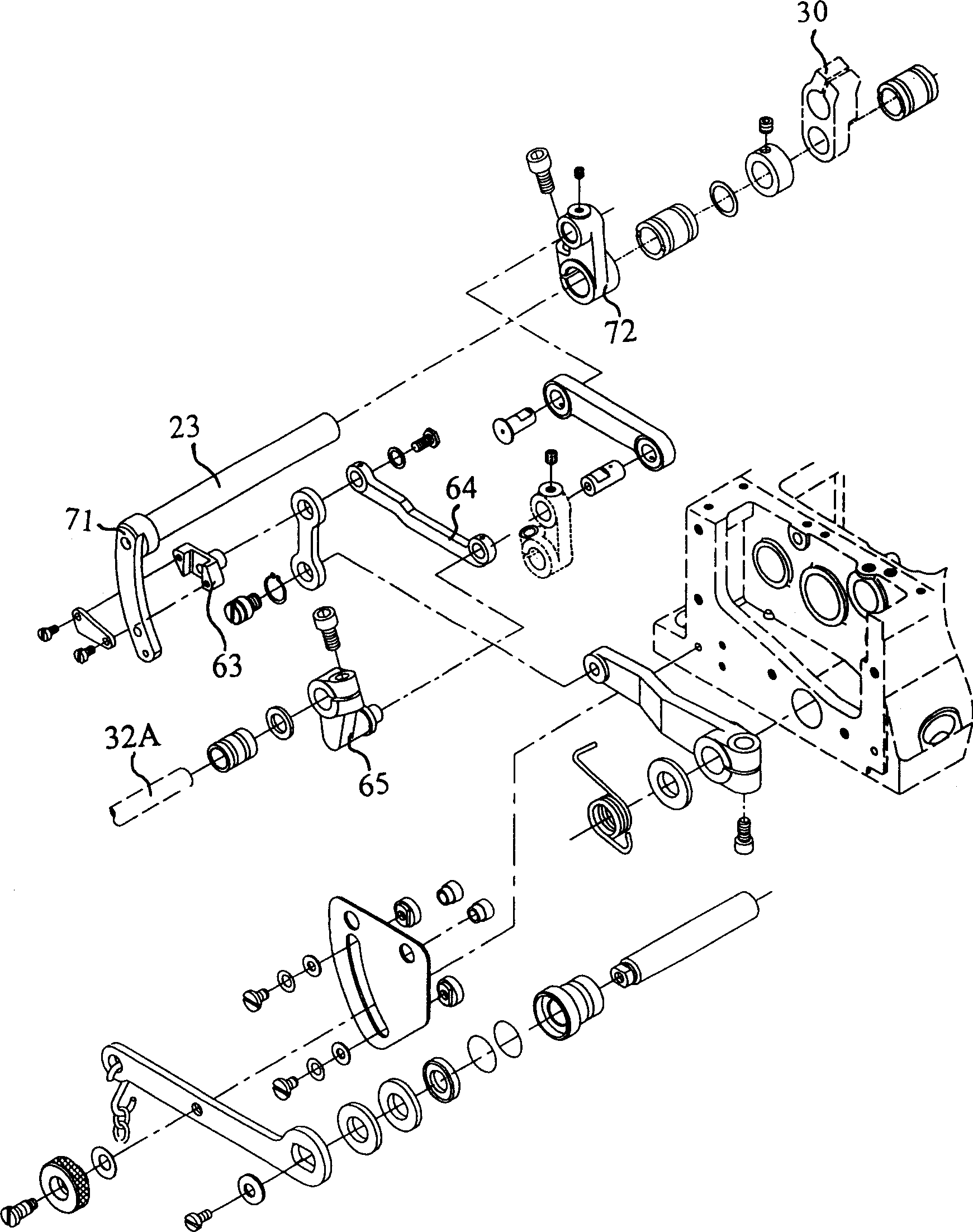

[0015] A needle bar 16 with a plurality of sewing needles 16a is provided at the lower front end of the arm 11 facing the needle plate 15, and the needle bar 16 sews clothes reciprocally up and down along with a driving mechanism (not shown). On the cylindrical portion 14 below the needle plate 15, a shackle (not shown) is provided, and at the same time, as Figure 4 As shown, the cylindrical part 14 is provided with a forward transfer tooth 17 and a rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com