Multi-independent-temperature-zone mesh stove and its control method

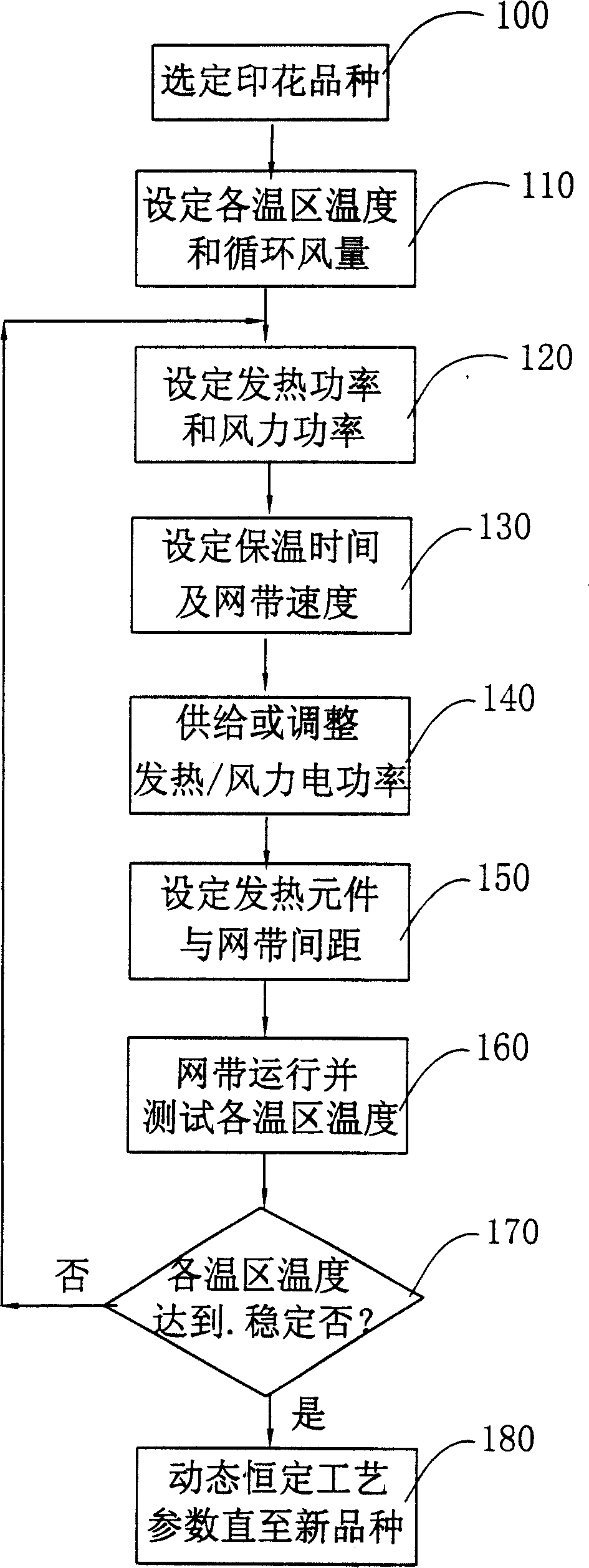

A control method and technology for a mesh belt furnace are applied in the field of textile printing, dyeing and drying furnaces, which can solve the problems of complicated adjustment work, inability to accurately realize independent temperature control, and difficulty in ensuring process adjustment stability and reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

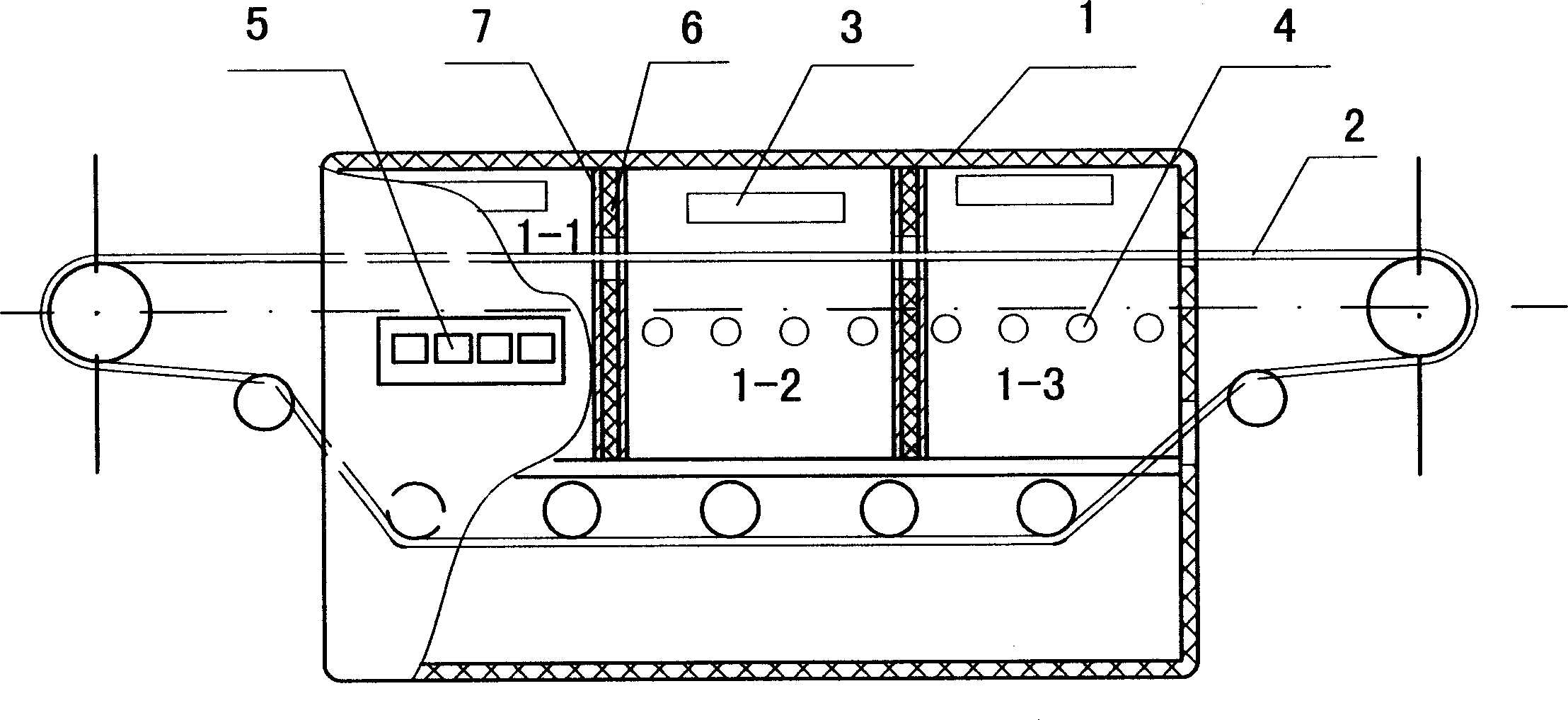

[0015] Such as figure 1 Shown: is a mesh belt furnace with three independent temperature zones of the present invention, the mesh belt furnace includes a furnace body 1, a transmission mesh belt 2 installed inside the furnace body, a heating element 3, a wind power system 4, and a control furnace The control system 5 of process parameters such as temperature and wind force adopts a microcomputer processor in the control system 5, and a memory for storing a temperature control mode database is integrated in the microcomputer processor. The mesh belt furnace is provided with three relatively independent heating temperature zones 1-1, 1-2, 1-3 along the longitudinal direction of the transmission mesh belt 2, and in each independent heating temperature zone 1-1, 1-2, 1 -3 is provided with independent heating elements 3 and independent wind power systems 4; the control system 5 includes heating power controllers (not shown in detail) and wind power controllers (not shown in detail)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com